According to the U.S. Bureau of Labor Statistics, hundreds of thousands of people in the U.S. work as welders, cutters, solderers, and brazers in industries like manufacturing, agriculture, aerospace, construction, petrochemical, food and beverage, and more. It’s clear that welding is a pillar that supports and is essential for much of the U.S. economy. In fact, many industries where large assemblies are required, such as shipbuilding, power plants, and large-scale construction, likely would not exist without welding processes.

To produce high-quality welds, very skilled professionals and the use of the right equipment and the correct process for the project at hand are also necessary. For example, joining pipes or tubes can be done manually; however, it involves challenges that are not easy to overcome, not the least of which is the need to achieve a consistent weld throughout a 360-degree rotation. The best answer to the difficulties of welding pipe and tube is an automated orbital welding process. Let’s delve a bit deeper into when to use orbital welding and what type of process to use.

What Is Orbital Welding?

As the name implies, orbital welding involves rotating the welding arc through an orbit or complete revolution to secure two metal structures. Most often, the pieces being joined are tubes or pipes; however, one of the pieces may be a pipe or tube and the other a tubesheet or plate used to support the tube. Orbital welding is used for pipe bends, butt welding, flanges, valves and T-fittings, as well as for welding oil storage tanks, boilers, heat exchangers, and other energy system applications.

Manual Versus Orbital Welding

As with other technical skills, becoming an expert welder takes years of experience. Unfortunately, in the U.S., the demand is outpacing the number of qualified welders needed. It is estimated there will be a shortage of about 400,000 workers within the next few years. Coupled with welder shortage, the advanced skill and expertise required for performing many types of industrial pipe and tube welds make orbital welding a natural choice for many of these applications.

Advantages of Orbital Welding Over Manual Welding

Overall, orbital welding offers a number of advantages over manual welding of pipe and tube, including:

- Greater productivity: Orbital welding takes advantage of automation to rotate the weld arc around the workpiece. This eliminates the need for the welder to reposition themselves and to stop and start the weld for each quarter of the pipe, improving welding productivity.

- Consistent, high-quality welds: Automation and programming allow for greater precision and consistency than is possible over time manually.

- Simpler process for the welder: Welding around pipes, especially those of large diameter, places physical stress on the welder. This is eliminated with orbital welding, which enables a mechanically inclined technician to perform with adequate training.

- More cost-effective: Many aspects of orbital welding contribute to its cost-effectiveness, including faster production, fewer weld defects and rework, and the ability to use lower-skilled personnel.

- Safer process: Some welding projects have constraints attached, such as space and clearances, that can place the welder in potentially dangerous positions. Fumes and radiation can also be hazards during manual welding. Orbital welding allows the welder to be at a distance from the joint being welded while managing the process through a remote weld pendant.

As the list above shows, there are many advantages of orbital welding over manual processes. Below, we’ll take a look at when these advantages should be leveraged.

When to Use Orbital Welding

As a mechanized welding process, orbital welding removes a good deal of the physical challenges of manual welding, resulting in a more consistent, reliable, and safe operation. However, there are still situations where a manual process may be a better choice. As an example, for one-off projects of limited size, the costs associated with acquiring and learning to use orbital welding equipment may not be justified. The table below lists some situations where orbital welding may be able to reduce welding costs. If you are considering an orbital welding process for your project, ask yourself the following questions:

| Are precision and consistency high priorities? |

| Is the workspace difficult for a welder to access? |

| Is the project a high-specification and/or high-volume job? |

| Is the environment harsh (e.g. low visibility, tight spaces, presence of radiation or dangerous fumes)? |

| Do welding parameters need to be monitored or traceable? |

| Are few skilled welders available? |

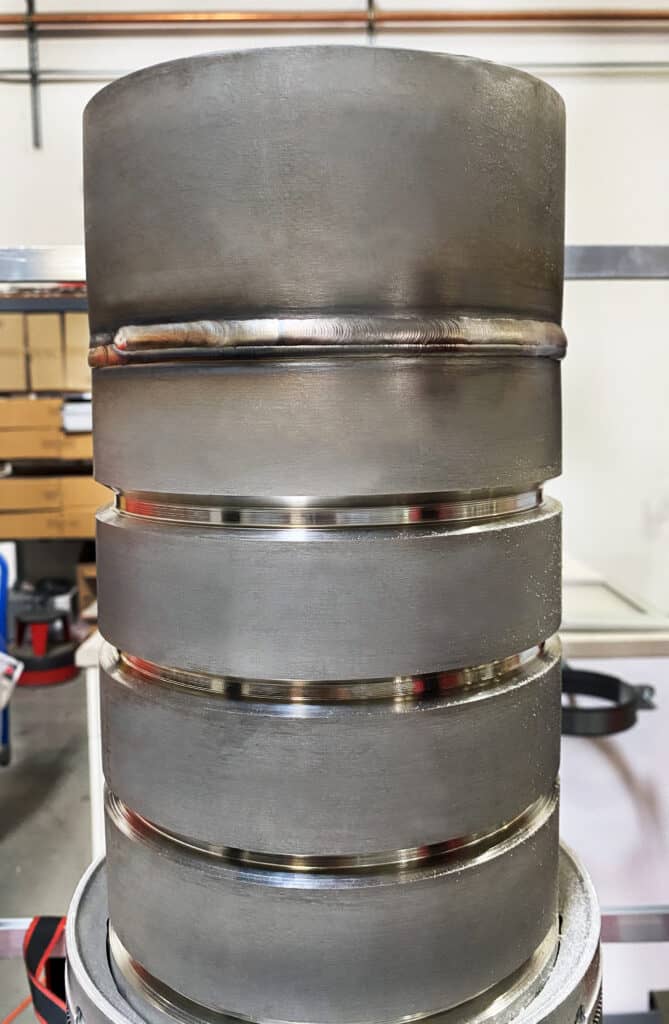

If you can check yes to one or more of the questions above, then orbital welding may be the best option for your project. One of the best uses of automatic orbiting welding is the gas tungsten arc welding (GTAW) process, which was used to create the high-precision welds in the image below.

So, when should you use orbital welding? Many projects can benefit from the regularity, precision, and cleanliness of high-quality GTAW orbital welding, whether the welds are on thin-wall tubing, large-bore piping, a tube-to-tubesheet assembly, or something else. As evidenced by the consistency of welds shown in the figure above, if your project is a good candidate for orbital welding, the high-quality results speak for themselves.

Arc Machines, Inc., specializes in high-quality, precision orbital GTAW welding and has been a leader in advanced welding technology processes and equipment since its founding by former NASA engineers in 1976. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.