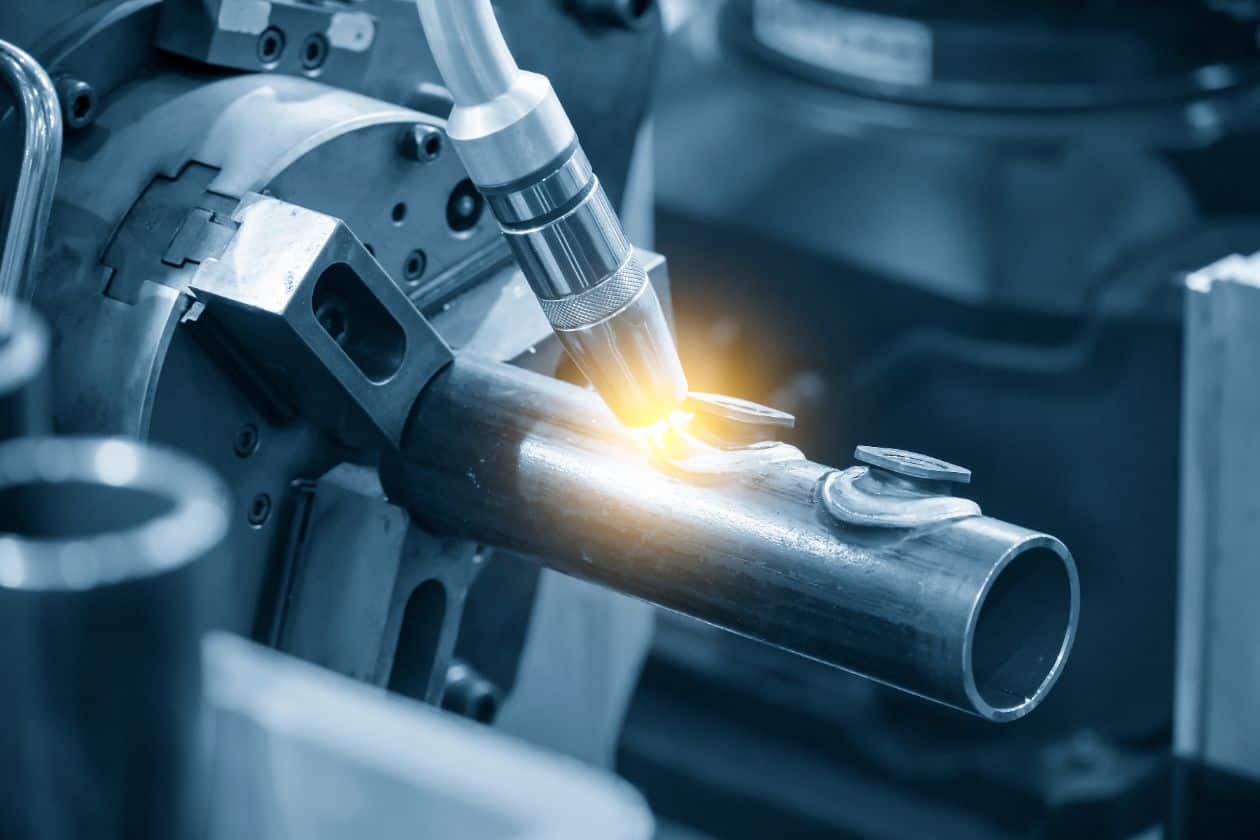

Welding has always been a demanding skill requiring significant time and dedication to master. And welding expertise is essential for GTAW, or TIG, welding, which is one of the most difficult techniques to perform manually. However, welder shortages, an emphasis on welder safety, and the availability of new technologies have resulted in smarter welding driven by automation. For piping systems, orbital TIG welding leads the way as an automated process that removes the welder from the hazards of the workspace and leverages advanced technology. Further, robotic TIG welding is gaining traction as a solution for improving your piping system assembly project when coupled with an advanced robot programming software tool.

What Is Robotic TIG Welding?

GTAW, or TIG, welding is widely considered the best technique for the permanent assembly of piping system elements where precision, quality, and efficiency are primary requirements. This includes pressure vessels commonly used in energy generation facilities and sanitary systems such as food and biopharma processing. TIG welding requires expertise and is a relatively slow, meticulous process; therefore, it is performed best by utilizing orbital welding equipment. The quality and precision of welds produced by TIG welding make it an excellent candidate for robot implementation.

Robotic TIG welding can be defined as follows:

| Robotic TIG welding is a software and electrically controlled process for bonding metals that require high-quality, precise weld joints. The system is composed of a robot or robot arm, a computing unit for programming robot arm movements, a weld head positioned by the robot, a pressurized gas delivery system, as well as an electric power supply and controller. |

Advantages of Using Robots for GTAW

The use of robotics can enhance the already precise TIG welding process by adding more flexibility to the positioning of the tungsten electrode and welding tip. For some robots, this precision can be as fine as .001 mm. Additionally, robots are impervious to physical safety hazards—including toxic gases, such as hexavalent chromium, UV radiation, and glare—that accompany many pipe welding applications. Perhaps the most significant advantage of robotic TIG welding is its impact on welding workflow. Not only can robots operate for extended periods without servicing, but they can improve efficiency by virtually eliminating bad welds that lead to process downtime and the need for extra materials.

How to Improve Robot Performance for TIG Welding of Piping Systems

To maximize the use of robotics for your piping system projects, follow the guidelines listed below.

Optimizing Robotic TIG Welding of Pipes

- Follow best practices for your robotic welding programming

- Avoid using robots from different manufacturers to simplify software integration

- Utilize tandem robots to reach difficult positions

- Leverage offline programming for high-mix, low-volume welding

- Use the best TIG orbital welding equipment

By instituting the suggestions listed above, manufacturers can ensure the robotic TIG welding process delivers superior results, especially when the industry’s best welding equipment is coupled with advanced robot programming software.

READY TO CONNECT?

Arc Machines, Inc., since its founding by former NASA engineers in 1976, has been an industry leader in solving difficult problems with innovation and advanced technology. This has led to the development of industry leading orbital welding machines and weld heads that can integrate with advanced software to build robotic TIG welding systems to optimize weld consistency and quality. This excellence is only enhanced by AMI’s expert advice and support. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.