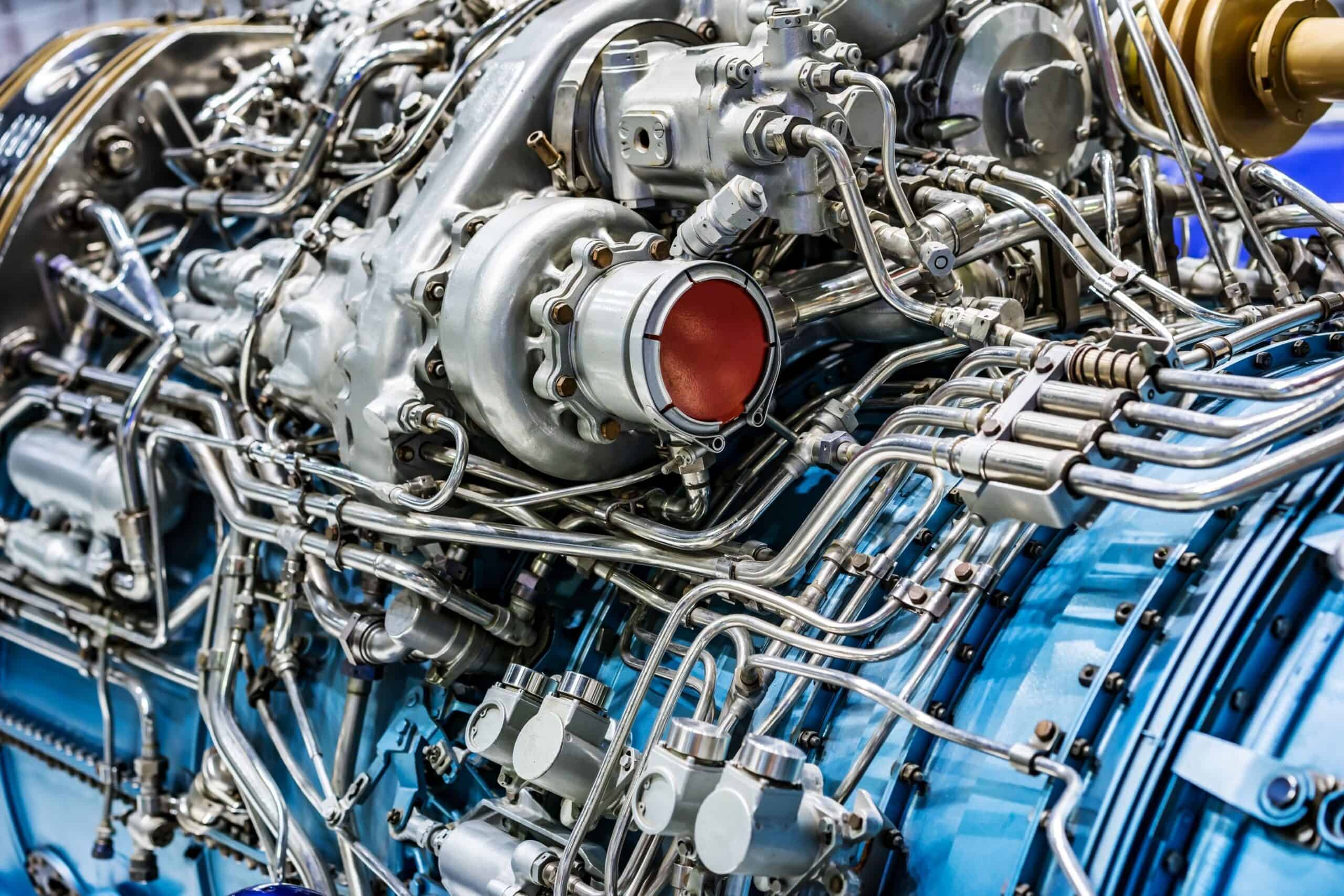

Today, industrial production is in the midst of a revolution. And this latest industrial overhaul, commonly referred to as Industry 4.0 or manufacturing 4.0, significantly impacts the welding profession. Key aspects of this trend are its emphasis on attaining higher quality and greater efficiency through automation, robotics, and software. Additionally, when weld strength and reliability are primary concerns, the best materials are also required. As a result, welding titanium pipe is gaining acceptance for many applications beyond aerospace, where titanium historically has been utilized for hydraulics and other lines.

Why Weld with Titanium?

Manufacturers once considered titanium an exotic metal, and its usage, in terms of piping and tube, was predominantly limited to aircraft applications. However, as the demand increased for stronger, lightweight materials for automobiles and other systems, titanium has continued to garner more attention due to its many advantageous properties.

Advantageous Properties of Welding Titanium

The strength to density ratio of titanium is better than that of other materials like stainless steel used in many welding applications.

One of titanium’s greatest welding assets is its resistance to moisture-driven corrosion. This property expands potential titanium pipe and tube welding applications to include industries like shipbuilding.

Although brittle at cold temperatures, titanium is ductile at high temperatures and retains its shape well.

Compared to steel and aluminum, titanium has a very high melting point, providing an advantage for welding processes that utilize electrodes.

How to Optimize Welding of Titanium Pipe and Tube

Due to a high melting point, titanium pipe and tube do not easily lend themselves to autogenous welding. However, when coupled with the best tungsten electrodes, a GTAW process can be optimized to produce the highest quality welds.

The Best TIG Welding of Titanium Pipe and Tube

By automating the welding process, manufacturers can leverage the consistency and high-quality weld beads produced by TIG welding.

Welding process quality is only as good as its implementation equipment. Be sure to keep your equipment in top condition by following a preventive maintenance program to minimize the likelihood that any contingency could take your project offline.

When working with titanium, the operator should keep the weld pool clean to avoid contamination that could cause the weld to be brittle.

Nitrogen and oxygen can diffuse into titanium and cause brittleness.

By following these guidelines when welding titanium pipe and tube, you can take advantage of the properties that are expanding titanium’s ever-increasing application areas.

READY TO CONNECT?

Arc Machines, Inc., since its founding by former NASA engineers in 1976, has been an industry leader in producing high quality and high tech welding equipment. This includes orbital welding machines and weld heads that make it easy to leverage the advantages of welding titanium pipe and and tube. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.