Orbital welding plays a critical role in joining tubes and pipes across many industries. However, specific industries and applications will often present unique welding specifications and require specialized welding equipment for best results. AMI’s weld head and power supply offer solutions for a wide range of applications:

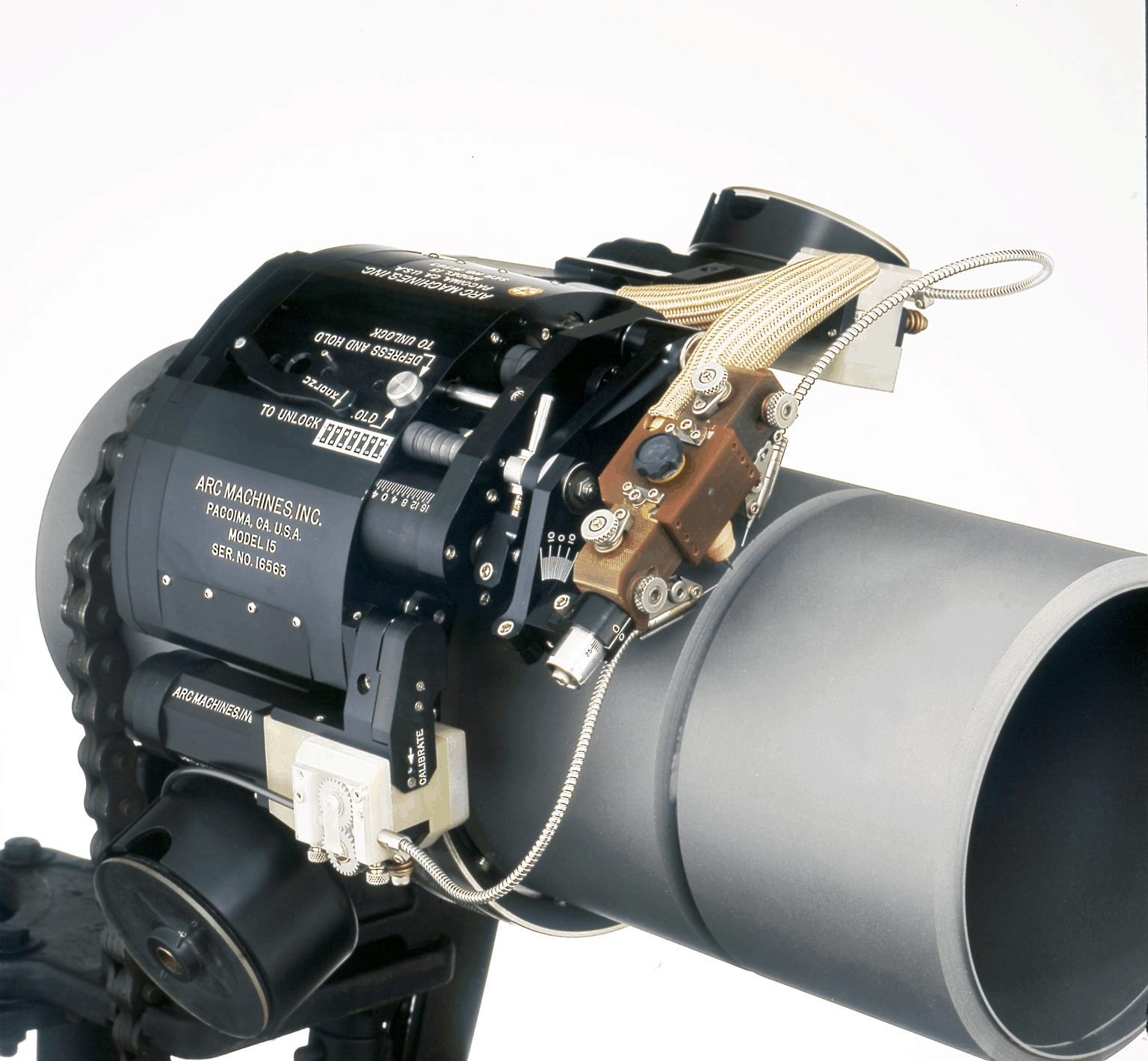

Orbital weld heads clamp to the fixed pipes on a set track or guide ring to perform the weld. As the weld head is mounted to the workpiece and automatically driven, weld consistency is easy to maintain. Fixed parameters allow the weld head to reliably produce uniform, high-quality results.

The power supply supports orbital welding by optimizing the available electrical power and enabling welders to control elements of current flow—including voltage, amperage, and polarity—for the desired welding application. This level of control allows operators to monitor welding process parameters that include feed speed, arc length, and more. As a result, industries can leverage these controls to achieve consistency and quality in precision-oriented applications such as semiconductor manufacturing.

Benefits of Orbital Welding Equipment

AMI provides orbital welding equipment specifically designed to meet a wide range of requirements to achieve industrial expectations. When compared with manual welding, the automated tools operate consistently and reliably without error or fatigue. Increased productivity and efficiency, along with waste reduction, can also balance the initial investment. With tools suitable for a wide range of applications, manufacturers can leverage the following benefits: