One of the most important factors in any high-purity gas tungsten arc welding (GTAW) project is the quality of the tungsten electrode used. If the tungsten is not sufficiently pure, the weld may need to be scrapped and redone, which lowers productivity and increases material costs. High-purity, high-quality tungsten electrodes create reliable, repeatable, and predictable welds for even the most demanding projects.

Why AMI Tungsten Electrodes?

AMI offers tungsten electrodes made by Wolfram Industrie in Traumstein, Germany. Wolfram specializes in manufacturing tungsten electrodes that are factory ground and polished with a high degree of precision. All of our tungsten electrodes boast the following characteristics.

AMI Tungsten Electrode Characteristics

- High purity

All our tungsten electrodes begin from powder containing 99.5% or more pure tungsten. - Consistent Weld Quality

Low burn-off and consistent material distribution across electrodes ensure reliable weld quality even on the largest of projects. - Pre-ground and Polished

Electrodes are pre-ground and polished to offer superior precision and consistency.

- Excellent Ignitability Characteristics

Our electrodes are built for optimum ignition reliability. - Stability

Our pure tungsten or tungsten-alloy electrodes are tested after manufacturing to ensure stability.

Buying Pre-Ground, High-Quality Tungsten Electrodes

No matter what type of GTAW project you are working on, safety and quality control are crucial. Common procedures like grinding and replacing electrodes are not always feasible as they require additional man-hours and equipment and may result in inconsistent weld quality. A better option is to rely on pre-ground tungsten electrodes to ensure a proper grind angle as well as weld precision and reliability.

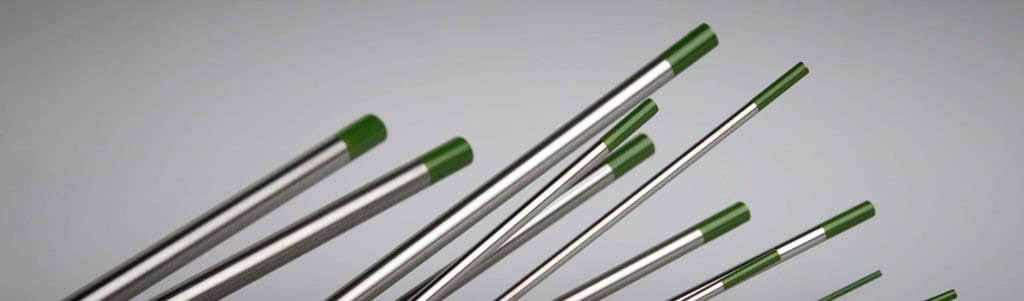

Pure Tungsten Electrodes

Pure tungsten electrodes, which are color-coded green, are made from powder of at least 99.5% purity. These electrodes have good ignitability as the temperature increases at the tip. Pure tungsten electrodes are typically used for projects such as AC welding on aluminum and magnesium alloys.

Thoriated Tungsten Electrodes

Containing as much as 4% thorium dioxide, thoriated tungsten electrodes have higher ignitability than pure tungsten. These electrodes are very versatile, and thoriated tungsten usage includes narrow gap welding and other applications where stable electron exit is mandatory.

Lanthanated Tungsten Electrodes

Aside from thoriated, lanthanated tungsten electrodes are the most versatile. They are used for TIG, orbital, resistance, and plasma welding. These electrodes contain no more than 2% lanthanum (III) oxide and can also be used for AC welding of aluminum.

Ceriated Tungsten Electrodes

The use of ceriated tungsten electrodes is on the rise globally, and this alloy may eventually replace thoriated tungsten as it exhibits better ignition behavior. These electrodes are best used at low amperages.

Zirconiated Tungsten Electrodes

Zirconiated tungsten electrodes are used almost exclusively for TIG welding. They have a low alloy content (0.8% zirconium oxide) and create highly pure welds.

Your welds are only as good as the electrodes you use. High-quality pre-ground and polished tungsten electrodes offer the advantages of reliability, consistency, and precision to support even the most demanding GTAW applications.

READY TO CONNECT?

For inquiries regarding tungsten electrodes, contact sales@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs.