Nuclear energy represents one of the safest forms of energy production in use today. However, risks are ever-present. Nuclear power plants have supplied electricity for over a half-century now, and the industry has not escaped catastrophe: we are all familiar with Three Mile Island and Chernobyl. While we know that safe nuclear energy production is the norm, it is essential to mitigate all risks.

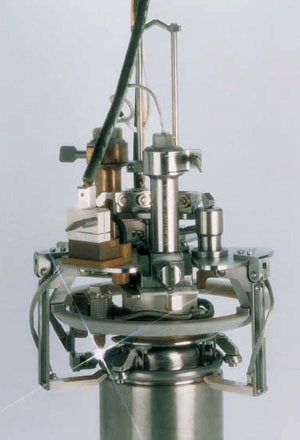

Seal and weld failure for pressurized storage containers presents one of the greatest risks at nuclear power plants. Pressure vessel welding quality is critical for nuclear power and other applications—such as where heat exchangers and boiler tubes are used. Choose the most reliable process for your applications, automated TIG welding, and the best equipment—available from Arc Machines (AMI).