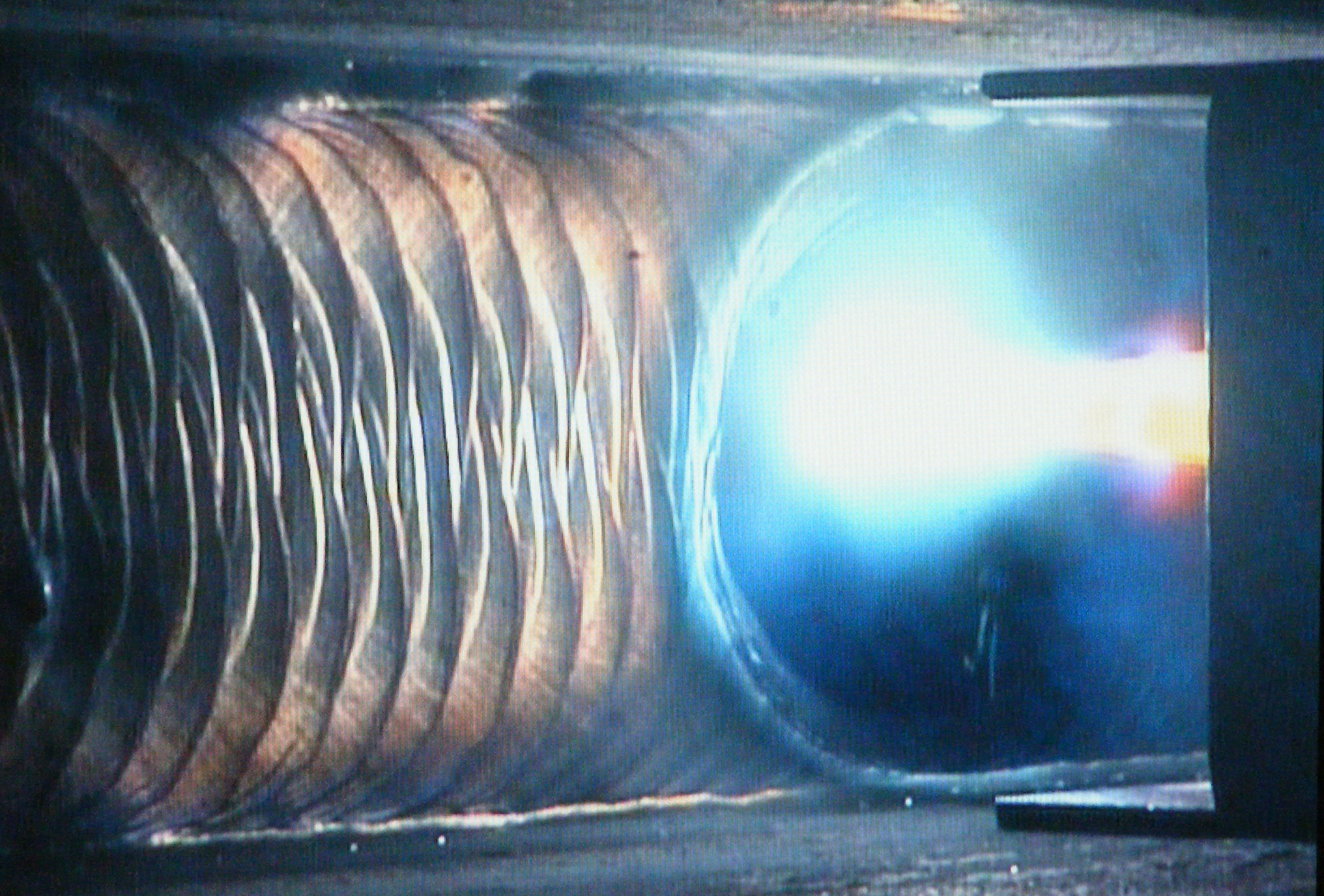

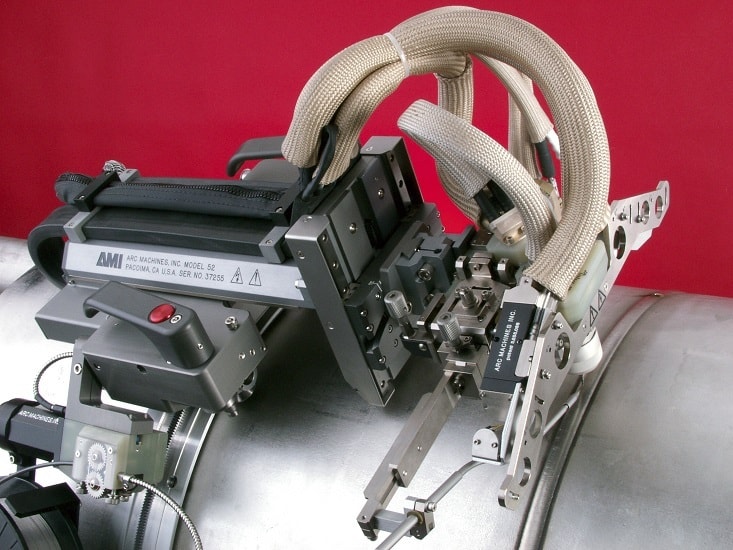

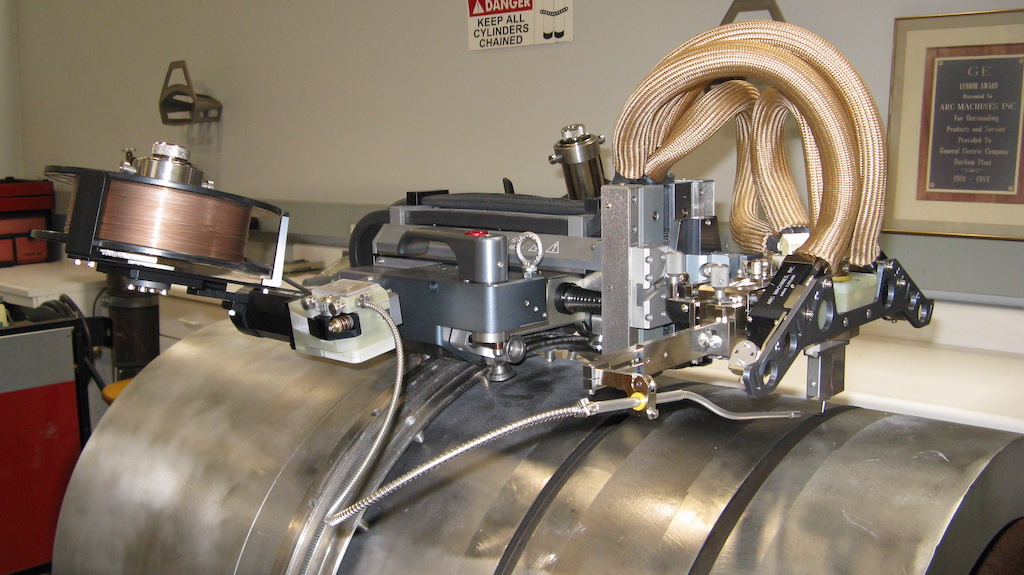

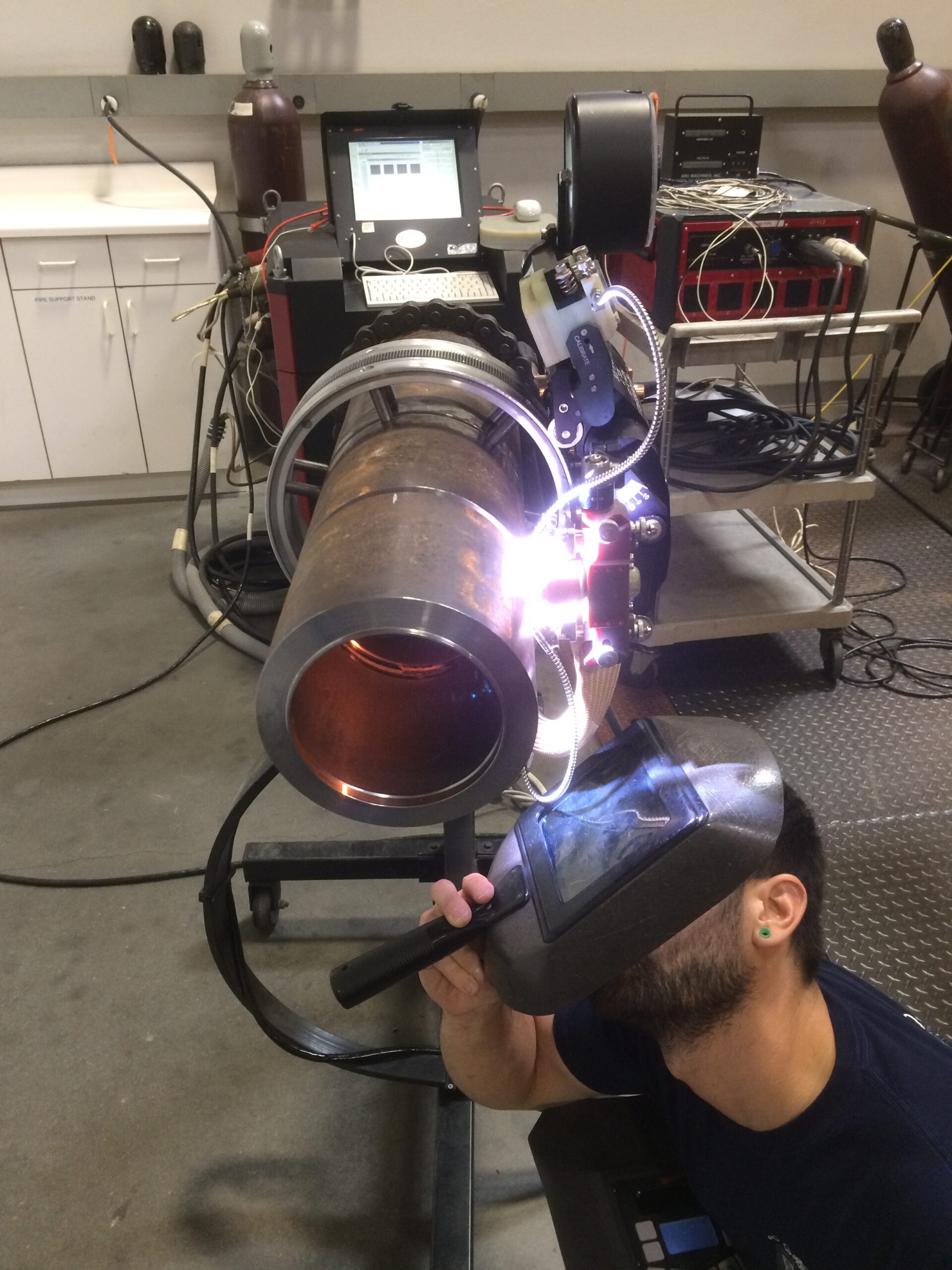

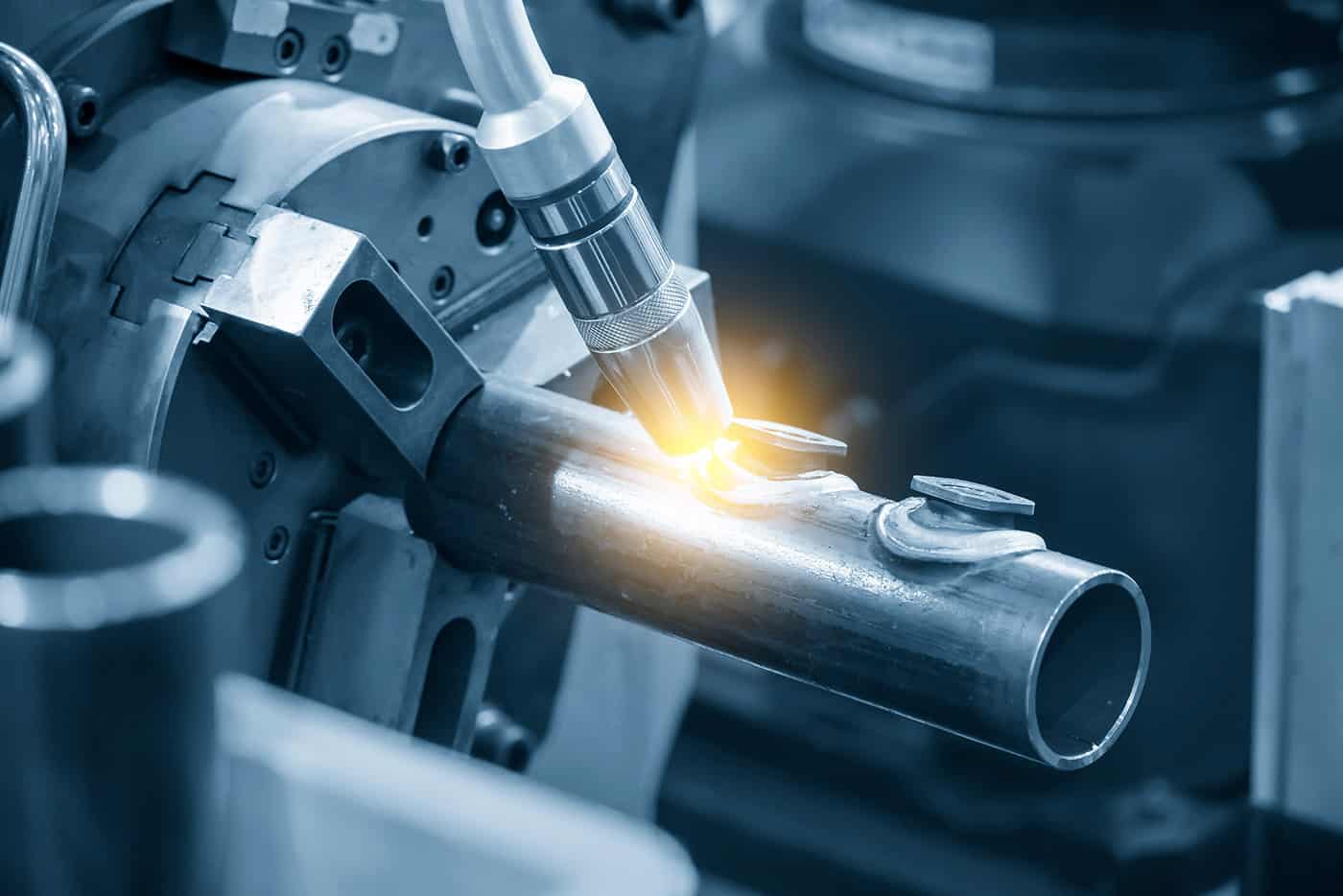

Pipe is notoriously challenging to weld; welders must manage constant changes in arc length. Positioning as the welder moves around the pipe is seldom optimal. The difficulty is high enough that many would prefer to position the electrode in a fixed position and rotate the pipe beneath instead. This is…