Pipe and tube welding is hard. It is so difficult in fact that it has its own dedicated certification process called 5G to weld the circumference of a horizontal fixed pipe. This pipe cannot be moved to make things easier, and if a welder produces a qualified weld and receives a 5G certification then they are widely considered to be qualified to do most any welding work with the arc welding process they got the cert with.

Orbital welding is an exception to this rule, even though it is working with the same sort of pipe used in 5g. It is an automated arc welding process. At first glance the skills needed to set up an orbital TIG welding parameter, and weld a bead around a pipe are very different. This discourages a lot of welders from even considering orbital welding as a possibility. So is orbital welding hard for manual welders to learn? The answer is no. With proper training experienced welders can learn the process and open up new career opportunities in fields they may have never considered.

Why Orbital Welding is Overlooked

The perception that orbital welding is hard has to do with two different factors. The first is a culture in industry at large that isn’t restricted to the world of welding. Namely the perceived divide between blue collar and white collar work. Welders working on the shop floor have traditionally been a part of the working class blue collar world. Whatever the actual color of their collars are.

Inputting parameters into a computer—what autogenous orbital welding boils down to—has belonged to the educated professional white collar world. This has meant that many welders never even consider the possibility that they might be a good candidate for an orbital welding position. The process seems like it belongs to engineers who can do calculations, and not to welders who spend their days staring at an eighth of an inch of glowing molten metal. This isn’t an accurate perception because:

|

|

Combined these factors mean that while orbital welding is technically sophisticated it still requires the know-how of a skilled and diligent operator to reach its full potential. It is welding automation that brings a welder to a new level, not a replacement for a skilled welder.

Is Orbital Welding Hard? Why the Answer is No.

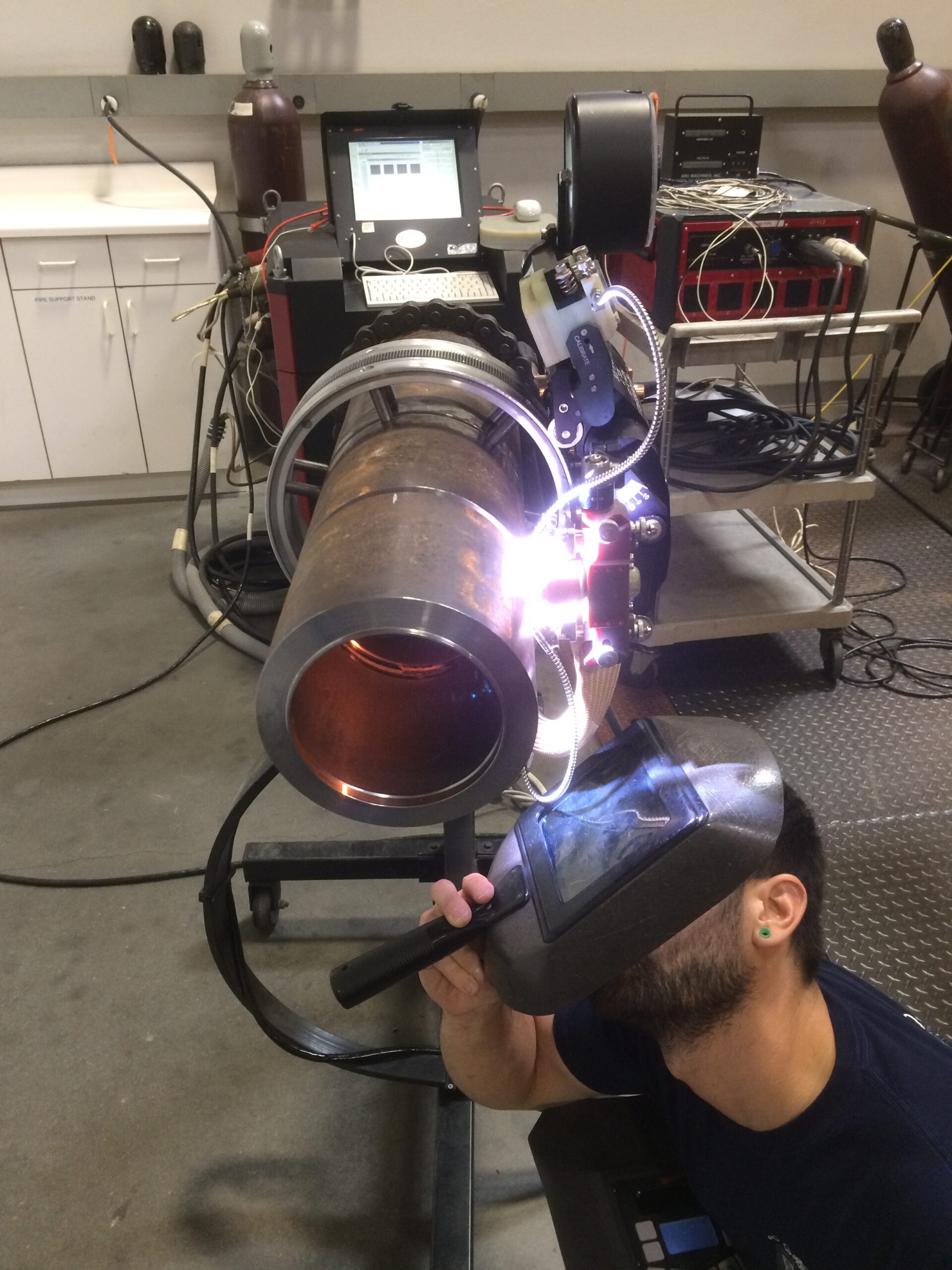

“Is orbital welding hard?” is a natural thing to wonder when confronted by digital readouts and screens displaying a range of factors someone may not have thought too much about. It is easy to be intimidated by new and sophisticated—and expensive—welding equipment. However, this isn’t necessary as modern orbital welding power supply types are intuitive, allowing interactions with welding parameters through a touch screen with a clear display rather than a confusing array of function keys that require an arcane combination to get the desired result.

The biggest reason is the question. “is orbital welding hard,” can be answered with a definitive no is that much of it comes down to the ability to read a puddle. This is something that most welders are already intimately familiar with. If you can read a molten puddle and know that you’re burning too hot and need to increase the arc distance or alternatively that travel speed can be stepped up then you already have many of the skills needed for orbital welding. All that is needed is training with orbital equipment to learn how to direct the machine to comply with your directions.

Orbital Welding Training and Equipment

Arc Machines is a longtime leader in orbital tig welding power supplies and weldheads that conducts regular training in using our equipment to its greatest effect. This can be conducted remotely by video conferencing, or in person by a specialist trainer with years of experience to help welders learn the machines, develop welding parameters, or prevent and troubleshoot common issues.

With professional training and long term support orbital welding is anything but hard. Arc Machines can even help you find the equipment that best fulfills your needs for high specification, high precision, and high purity TIG welding in aerospace, pharmaceuticals, petrochemical, and other industries.

Arc Machines, Inc. is an industry leader in developing advanced and orbital welding systems. To begin orbital welding training and make high specification TIG welding of pipe and tube easy with our experts contact us.