The history of orbital welding began with the need to fix a leaking pipe, albeit one that was destined to travel to the edge of space. From there, orbital welding heads grew to play a role in wastewater treatment, orbital sanitary welding for biopharmaceuticals, nuclear power, and even experiments on fusion power, among other things. Orbital weld heads are used in nearly every industry and come in various types that can be adapted for many uses.

Types of Orbital Welding Heads

The sheer usefulness of automated orbital welding has created many orbital welding heads intended for a vast range of purposes. This includes fixed and mounted weld heads that do not technically orbit the workpiece and are essentially orbital welding heads by association rather than technical accuracy.

| Orbital Weld Head Types | ||

| Closed Orbital Welding Head | Description | Applications |

|

A weld head that encloses the entire circumference of the tube, helping to encase it in shielding gas. Used for thin-walled materials that can be welded autogenously in a single pass. |

|

| Open Orbital Welding Head | Description | Applications |

|

Larger diameter pipe or thick-walled materials that require narrow groove pipe welding require an open orbital weld head. These mount to tracks that can be adjusted to fit around a range of pipe sizes. |

|

| Tube to Tubesheet | Description | Applications |

|

Tube-to-tube sheet orbital weld heads are unique. They create a filet weld on one end of the weld to securely join a tube to a sheet where several holes are made for several tubes. |

|

| Fixed/Mounted | Description | Applications |

|

Fixed and mounted weld heads are customizable for a range of applications. They can be fixed while a workpiece moves beneath them, or they can be mounted to robotic arms to perform a more specialized task. |

|

| Interior Diameter | Description | Applications |

|

Not all pipe and tube welding takes place on the exterior of the pipe. Joints may need to be welded from the interior occasionally, and pipe may need lining with a corrosion-resistant metal. |

|

| Specialized | Description | Applications |

|

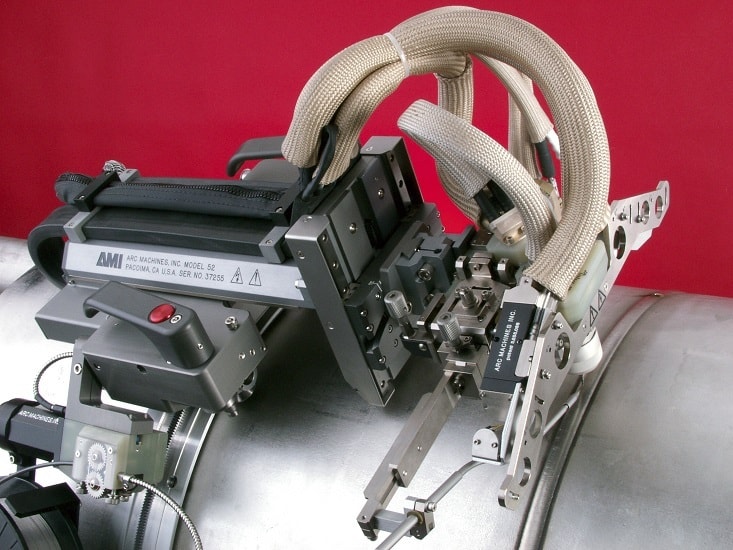

Specialized orbital weld heads take many forms. They are designed and made to fulfill a highly specific role. From the benchtop model left to specialized welding for sealed canisters, there are many options for these highly nuanced orbital weld heads. |

|

In addition to a wide variety of form factors and functional mechanisms, there are also a wide variety of welding types that have been incorporated into orbital welding heads. These include gas and flux-shielded processes and, on occasion, even unusual welding processes. However, the process has been inextricably linked since its inception to gas tungsten arc welding (GTAW).

Orbital Welding Heads: Gas Tungsten Arc Welding

GTAW orbital welding heads provide the highest quality pipe and tube welds barring some exotic welding techniques. These exotic techniques are generally too large to maneuver, meaning that they cannot orbit a workpiece. In most applications where a pipe must be fixed into place, it cannot be used. This leaves GTAW orbital welding heads as the highest quality choice for pipe welding in most applications.

Arc Machines, Inc. provides high-quality orbital welding heads and power supplies for GTAW pipe welding and other specialized industrial uses. Contact us to discuss your specific needs.