One of the most common uses for computer vision is tracking objects. This means identifying a particular object, remembering its specifics—dimensions, location, etc.—and then being able to follow that object as it moves around a frame of reference such as a video frame. Simple object tracking is much easier than object recognition. For example, it’s relatively easy to determine that there is a face in a video. A few well-known algorithms define things like the general shape and placement of features like the eyes, nose, and mouth. It’s much more difficult for computers to recognize a specific individual’s face, especially when complexities like different viewing angles and proportions add to the challenge. These challenges in facial recognition have equivalents when it comes to using computer vision in welding.

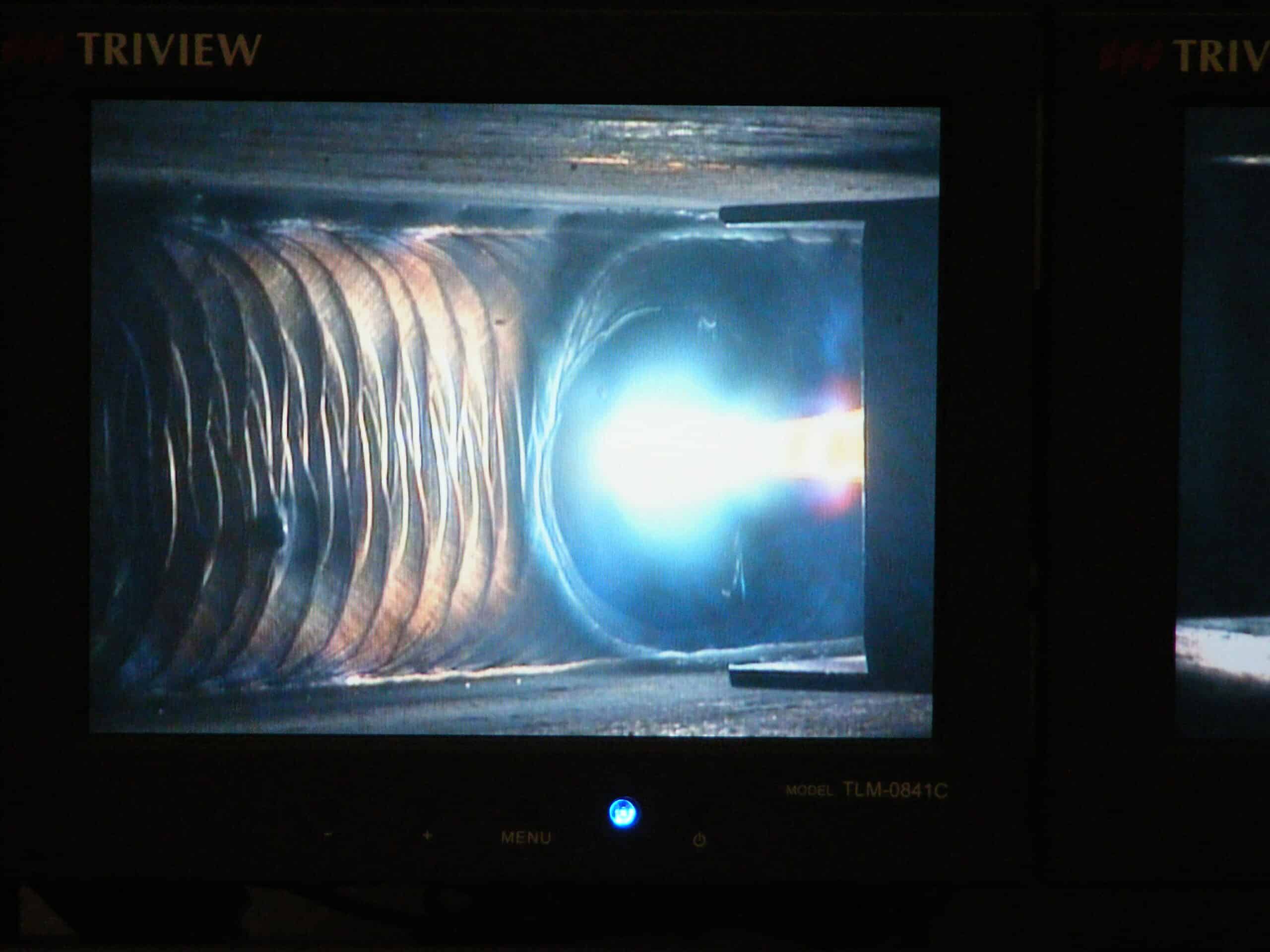

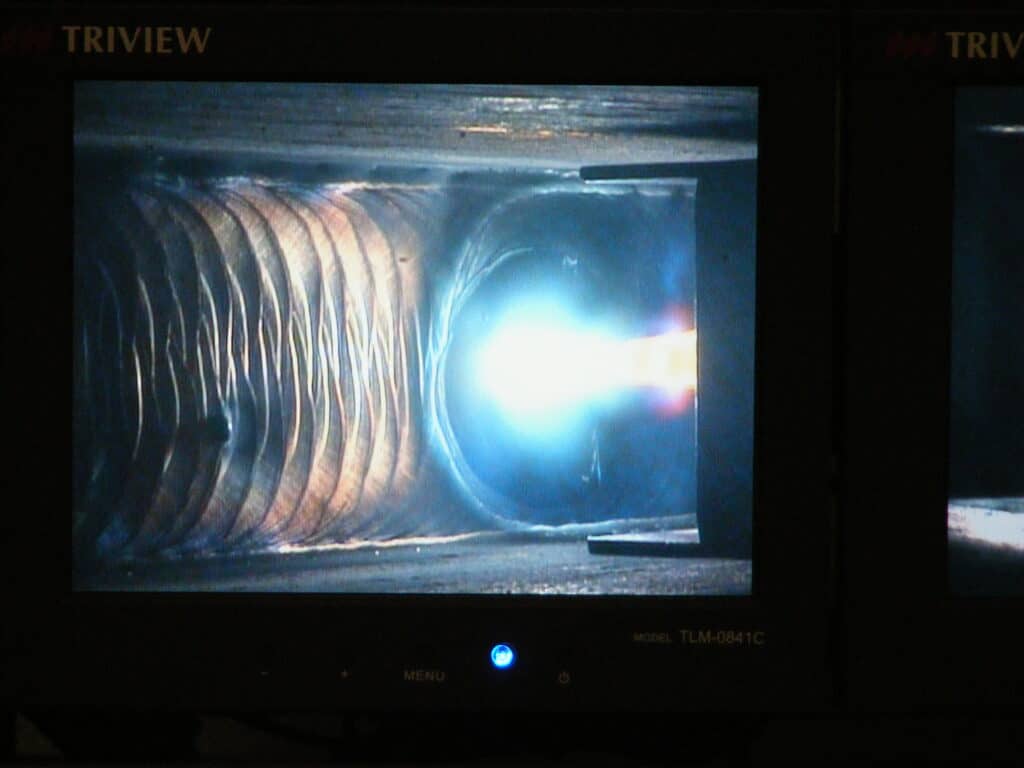

When it comes to recording a weld puddle, the mission to detect, measure, and track the weld puddle and the welding arc during an active weld is simple in theory. The practice of doing so using an arc welding monitoring system is not so easy. There are challenges in recognizing the shape and properties of individual weld puddles that make recognizing and recording a weld puddle with computer vision a challenge.

The Challenges of Using Computer Vision in Welding

It might be a surprise to some that computer vision struggles to track an arc and molten puddle. The arc is, after all, between 6,000 to 8,000 degrees Celsius and incredibly bright. It seems impossible to miss. As it turns out, this particular problem is a great way of illustrating the differences between how a human sees and how a computer sees.

Tracking the weld puddle is more difficult than tracking the arc, though not for the reasons that most might suspect.

The first step in using computer vision in welding is to identify what needs to be tracked. This will determine what steps and algorithms will be used to find the object or objects of interest and separate them from the background. One of the most common techniques is to find all of the edges in a scene presented to a camera and determine which edges outline the object you’re most interested in. In the case of welding, this will be arc and the weld puddle. Tracking the weld puddle is more difficult than tracking the arc, though not for the reasons that most might suspect.

How to Distinguish a Weld Puddle and Arc

The Canny edge detector, developed by John F. Canny in 1986, is often used to detect the edges of objects in any given frame. It uses multiple algorithms and the calculus of variations to detect edges. There are several steps to the process and many ways of tweaking the detector to be more or less sensitive, and this is normally a very successful method. However, it doesn’t do a good job of finding the ellipsoidal weld puddles that appear in most arc welding videos.

Part of that failure is that there is not a strong color or contrast difference between the edges and center of the puddle and the surrounding metal. Significant color-shifting and noise reduction, and the addition of other edge-detection algorithms, provide a way to track and record the weld puddle.

Once the frames have been corrected and filtered, a particularly good object tracker should only have to identify the object once. It should also be able to keep track of the object if it should become partially–or even fully–obscured from view for a period of time. Once the puddle is identified, that set of variables can be used to maintain tracking. Measurement should be a simple task after that.

Identifying and Tracking the Welding Arc

Another similarly difficult task is to find and track the weld arc. Here, edge detectors are meaningless, since there are no real edges to a weld arc, only differences in brightness. Using contour detection can detect and enable tracking of the welding arc. Contours in computer vision are best thought of as a curve joining all the points along a boundary with the same color/hue, intensity, or brightness. After color-shifting the image and adjusting it, the contours of a mostly circular arc light region should stand out in the frame.

Once the arc light is separated, finding and tracking the center of the arc light through all frames should be relatively simple. It should not be necessary to apply algorithms to track an object if it becomes occluded by another object. Neither the puddle nor the arc should become occluded during a weld.

A lot can be done using computer vision in welding for object detection and tracking. AI analysis of visual recordings captured by weld data monitoring holds the promise of significantly improving high-specification welding processes. The challenges posed by detecting and tracking the weld arc and molten puddle demonstrates how each implementation of computer vision is completely different. The techniques that work in one case will be useless in another. This is why it is important to not only be familiar with as many computer vision algorithms as possible, but to also know each one’s efficacy in different use cases.

Arc Machines, Inc. leads in technology for high-specification orbital arc welding, including computer vision application in object detection and tracking. For more information about AMI welding systems, contact sales@arcmachines.com. For service contact service@arcmachines.com. Contact us to learn more about custom orbital welding solutions.