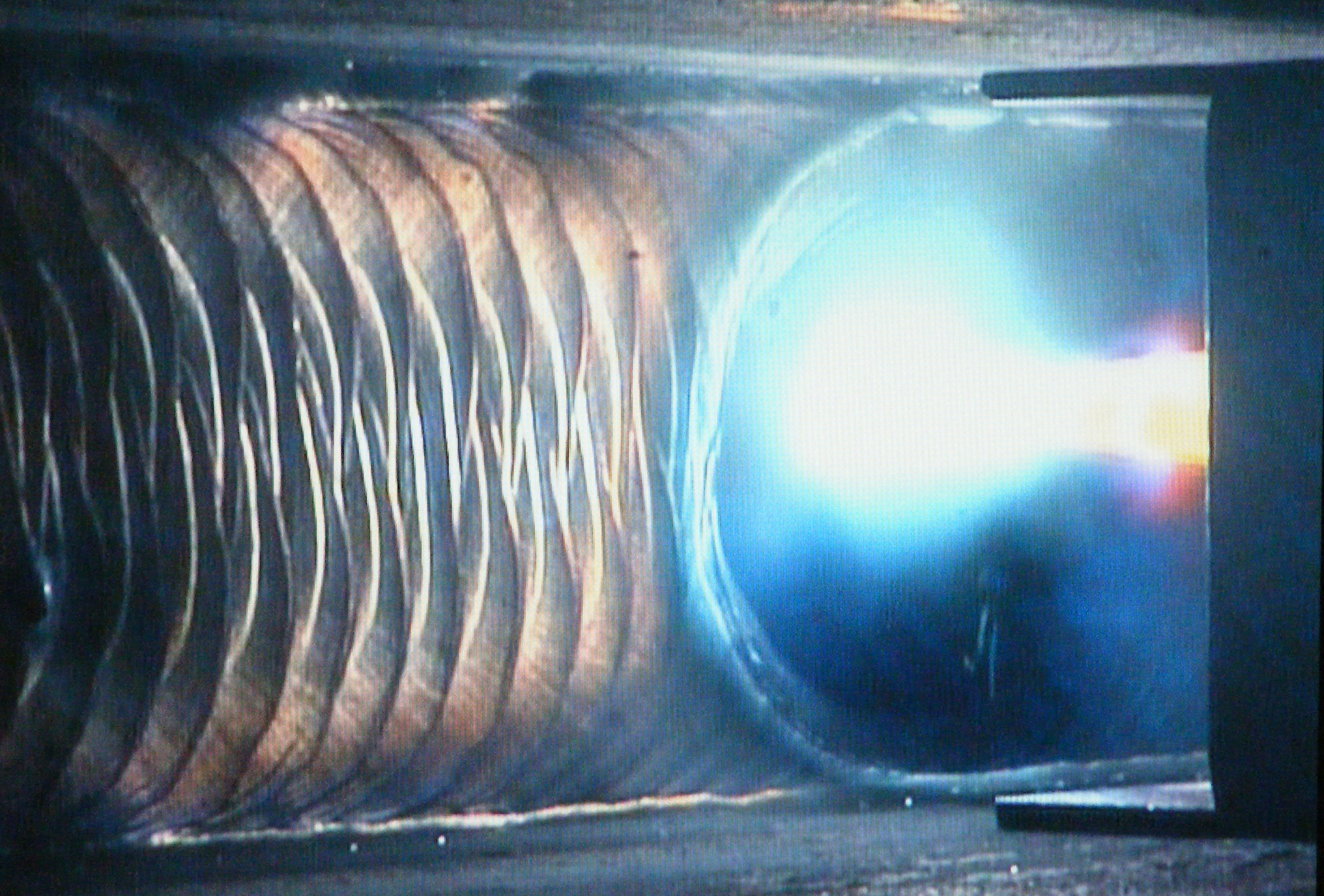

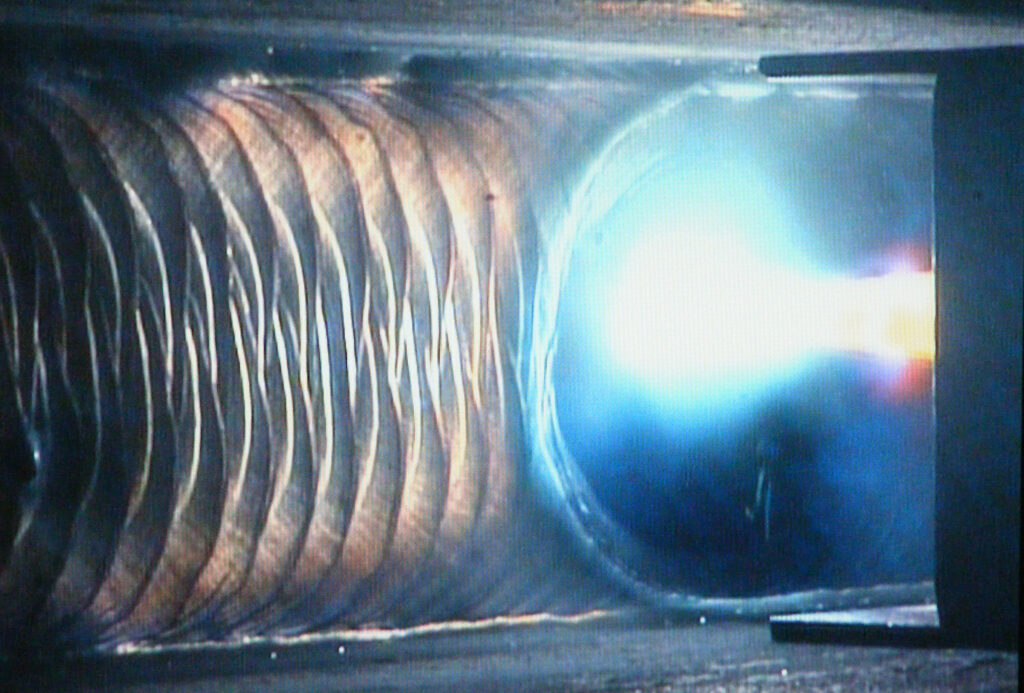

The term “weld pool” designates the molten puddle of metal liquified by the welding arc. It can be formed from the surface metal of the workpiece, filler metal introduced to the arc, or a combination of the two. In each case, the weld pool is subject to dynamics that are more usually the provenance of air and water.

One dynamic of particular concern is flow—and the difference between laminar flow, transitional flow, and turbulent flow. Weld pool turbulence is, as you might imagine, is related to turbulent flow; however, unlike the TIG welding gas flow rate where turbulence in the gas can ruin a weld, turbulence in the weld pool is not necessarily bad. Weld pool turbulence can actually enhance penetration and lead to a stronger, deeper penetrating weld with excellent fusion. Too much turbulence, though, can lead to defective welds. Weld pool turbulence, like most welding concepts, is managing the proper balance for the task at hand.

The Forces Driving Weld Pool Flow

Welding at its core is about using heat to transfer mass and bind it together at the molecular level. Flow is the driving force behind how mass and heat are distributed within the weldment. How the molten metal crystallizes and forms microstructures as it cools will largely be determined by the flow pattern created within it during its liquid state. A range of fundamental forces drive flow patterns, and their interactions in creating the molten metal affect its pattern of behaviors.

Fundamental Forces That Affect Flow Patterns

- Gravity: Gravity is the primary force affecting turbulence in the weld pool. It constantly pulls the molten metal away from the weld, except in flat positions. Gravity also plays a role in how molten material is distributed within the weld.

- Electromagnetic force: This force is responsible for melting the metal and generates a magnetic force that attracts molten material toward the center of the weld.

The fundamental forces noted above combine to create the following additional weld dynamics:

- Convection: Convection occurs when cooling materials, driven by gravity, move toward the gravitational source, regardless of its orientation relative to the weld. This process allows molten materials to rise against gravity before cooling. Convection affects the distribution of materials in the weld and influences the formation of microstructures.

- Buoyancy: Not all materials have equal densities, or maintain their density as they are heated or cooled. This causes some materials to rise faster than others when in a molten state, altering the material distribution within the weld.

- Surface Tension: A liquid tends to shrink to the minimum surface possible as it seeks a minimum energy state. In welding, surface tension creates an outward force that pulls the weld pool away from the arc toward the edges of the weldment.

These forces interact to create flow within the weld. The electromagnetic force is the strongest, enabling welders to manipulate the molten weld pool vertically uphill. Changes in the electromagnetic force significantly impact weld pool flow, turbulence, and the final weld properties.

Laminar Flow vs. Turbulent Flow

Flow in welding can be categorized into two types:

- Laminar Flow: Laminar flow occurs when a fluid moves smoothly along a regular path with minimal fluctuations or mixing of different materials. It is rare in nature, but can be engineered, such as the flow of air over an aircraft wing. In welding, laminar flow is observed when a highly viscous liquid quickly solidifies after the heat input of the electric arc moves past.

- Turbulent Flow: Turbulent flow is more common and exhibits irregular and unpredictable characteristics. It involves mixing different layers and materials. In welding, turbulent flow, or transitional flow, can lead to better mixing, a more even distribution of metals, deeper penetration, and improved fusion of weld sidewalls. Because turbulent flow can have such a positive effect on weld results, welder machines allow adjustable arc settings, such as arc force or arc control, to enhance weld pool turbulence and achieve desired welding outcomes.

Arc Settings and Weld Pool Turbulence

Arc settings play a crucial role in controlling weld pool turbulence. By adjusting the voltage or amplitude, these settings can compensate for a short arc or prevent the arc from grounding out. However, increasing the voltage has additional effects, such as raising the heat in the weld and reducing the viscosity of the molten puddle, ultimately enhancing weld pool turbulence. Welders often describe arcs that generate significant turbulence as “sharp,” while those leaning towards laminar flow are referred to as “soft.” These terms are based on the welder’s interpretation of the behavior of the puddle.

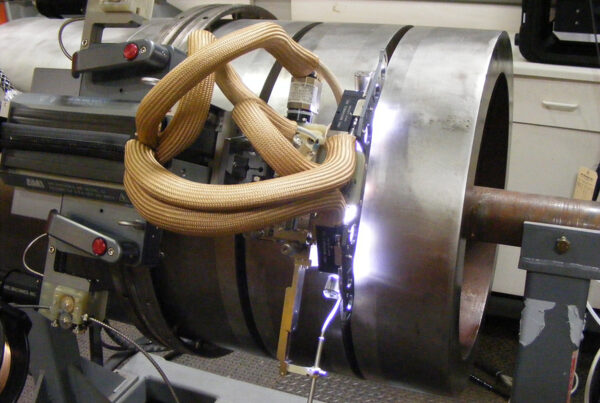

In orbital welding, if there is a lack of fusion in the results, it is necessary to increase the arc force or arc length settings in the orbital TIG welding parameters to achieve a satisfactory outcome. On the other hand, if burn-through or excessive heat affected zones become problematic, it is crucial to scale back the arc force and the amount of weld pool turbulence being generated. Adjusting these arc settings allows welders to fine-tune the welding process and optimize the quality of the weld.

Arc Machines Inc. offers full featured autogenous and pipe welding orbital GTAW power supplies with 100% duty cycles and advanced control over arc length, arc force, and weld pool turbulence and laminar flow.

Contact us to find out more about high-quality, durable, and sophisticated orbital welding equipment from Arc Machines.