The most popular arc welding processes are GMAW and GTAW. The GMAW process is faster; however, GTAW or TIG welding produces higher quality welds. For many industries; such as aerospace, the bar for quality welding requires the process be optimized. Meeting this demand begins with choosing the best materials. Therefore, knowing tungsten electrode types and uses is essential to make the right selection for your project.

The Different Tungsten Electrode Types and Uses

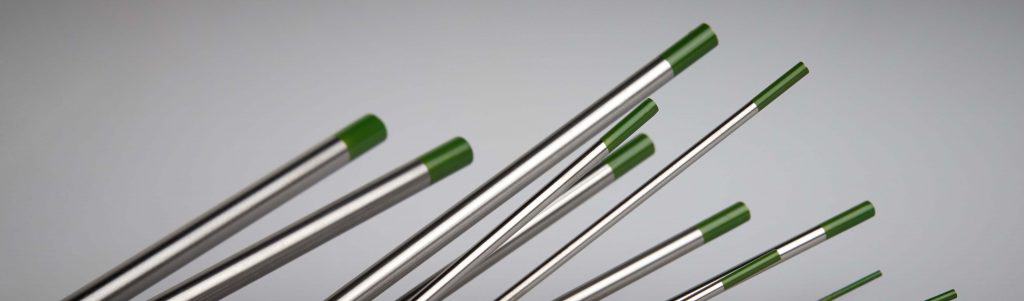

Tungsten electrodes are classified according to the type of additive, as shown in the table below.

| TUNGSTEN ELECTRODE | ||||||

| TYPES | USES | |||||

| Color | Additive | Tungsten (%) | Attributes and Applications | AC | AC/DC | DC |

| Green | None | 99.5 | Pure tungsten electrodes provide a stable Stable arc for AC welding. It can be used for DC, but typically is not. Common used with aluminum base materials. | ✔ | ||

| BrownWhite | Zirconium | 99.1 | Zirconiated tungsten electrodes are most often used for applications where the surface melting point is higher than inner materials. A good example is pressure vessels that must withstand high internal temperatures and pressures. | ✔ | ||

| BlackBlueGold | Lanthanum | 97.8 | Lanthanated tungsten electrodes give stable arcs, can be used at both low and high temperatures and are commonly used with a wide range of base materials. | ✔ | ✔ | |

| GreyOrange | Cerium | 97.3 | Ceriated tungsten electrodes can be used for both AC and DC. They use low amperage, arc stability and have good operational lifetimes. Typically used for thin and/or delicate metal applications. | ✔ | ✔ | |

| RedYellow | Thorium | 97.3 | This additive is radioactive. However, thoriated tungsten electrodes exhibit a reduced consumption rate, and lower deposition and strong arc starts. | ✔ | ||

As shown above, all tungsten electrodes have advantages that can be beneficial depending upon your application. For the best results, however, it is necessary to leverage the tungsten electrode types and uses optimally.

Optimal Tungsten Electrode Welding

The best TIG welding is achieved by instituting the best process. This is achieved by following the steps below:

Steps for an Optimized GTAW process:

Step 2: Choose the best method

The best method for high quality GTAW is orbital welding, which has the following attributes.

- Automation

- Accuracy

- Safety

Step 2: Choose the best materials

The best choice of tungsten electrode for your project should include

consideration of the following

Step 3: Choose the best equipment

Finally, it is important to select the proper equipment that will deliver

- Consistent performance

- Controlled operation

- Ease of use

Knowing the tungsten electrode types and following the steps above will enable you to create an optimal TIG welding process that satisfies the demands and requirements for your project, irrespective of industry.

Arc Machines, Inc. is an industry leader in supplying advanced and high-quality welding equipment and service. This includes orbital welding machines, materials, and expertise; such information about tungsten electrode types and uses to aid you in making the best selection for your project. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.