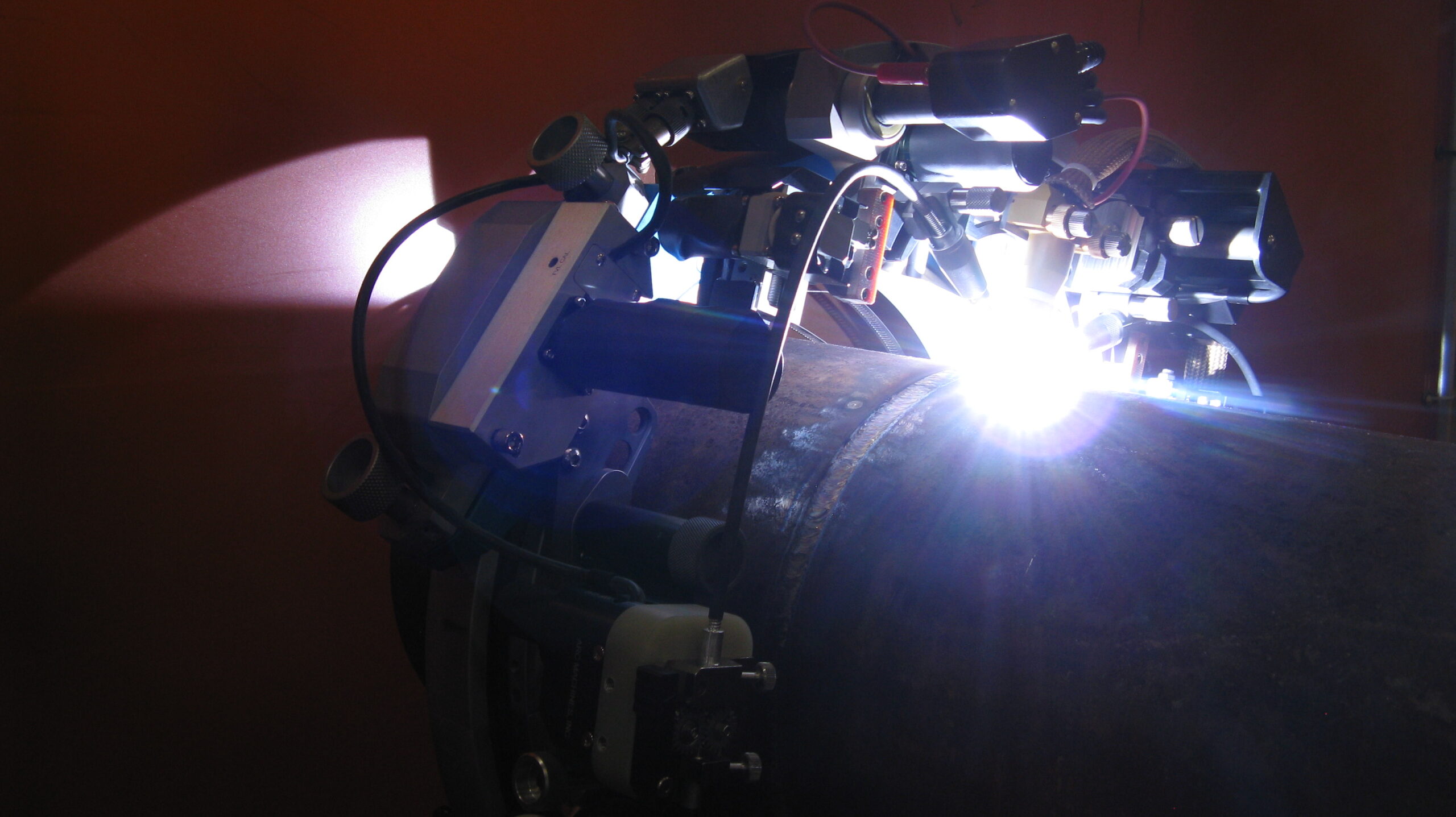

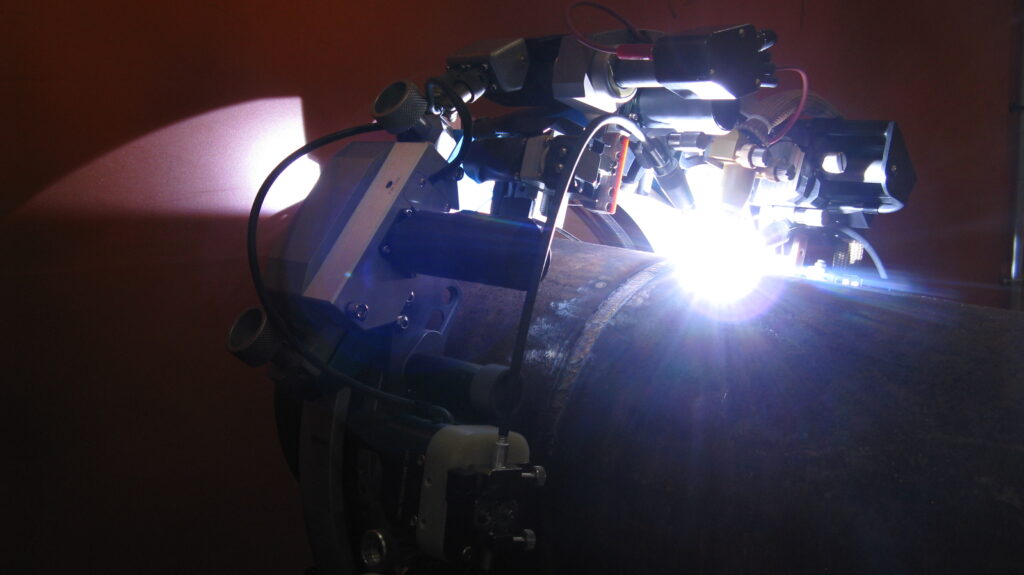

Multiple processes use an electric arc to generate heat and create a fusion between two metals– GMAW (gas metal arc welding) and GTAW (gas tungsten arc welding) are the two most prominent. Industries can create an arc manually or mechanically. Mechanical processes, such as orbital welding, are preferred when quality and precision are the main concerns.

Another factor to consider is whether to use GMAW or GTAW with an orbital process, but this depends on the time restrictions and quality standards desired for your welding application. In this article, we will compare GMAW vs. GTAW and identify which option would be the better to choose for the integrity of your welding process.

GMAW vs. GTAW: Features and Benefits

Gas Metal Arc Welding (GMAW)

GMAW, or MIG (metal inert gas), is a welding process that uses consumable electrodes and shielding gas to establish an arc with the base metal. While the inert or active shielding gas protects the weld pool from contamination, the wire is continuously fed to create fusion. The process is faced-paced, thus, much more economical and productive compared to processes like GTAW. For large-scale welding projects with time constraints, such as pipeline welding, orbital GTAW is the ideal technique to use. The speed of GMAW when paired with the automation of the orbital system, can provide the following benefits:

- Ability to weld in any position

- Fast and productive weld

- Capable of welding a wide range of metal

- Quality weld with precise parameter control

Industries have been biased towards orbital GMAW/MIG when the time and cost criteria are strict. However, when the priority is quality, GTAW/TIG should be the chosen technique.

Gas Tungsten Arc Welding (GTAW)

GTAW or TIG (tungsten inert gas) creates fusion by using a non-consumable electrode to generate an arc. Similar to GMAW, the process uses an inert shielding gas to keep the contaminants away from the weld pool. But unlike GMAW, the GTAW process is excruciatingly slow. This can be a concern in today’s production environment when high demand, speed, and productivity are often prioritized.

However, for precision welding applications, in which quality is the key, GTAW is by far the ideal option. The constant power supply produces a stable arc which helps to create a uniform and durable weld. When automated with orbital welding, the issue of speed with the GTAW process can be minimized to a certain extent. There are a few other advantages.

- The welding parameter is controlled, so the weld produced is precise and high-quality.

- The inert gas helps create pure and defect-free weld, no spatter and a better surface finish.

- Dissimilar metals and a wide range of thicknesses can be welded with precision.

- Precision welding helps reduce errors and waste.

Ideal Welding Process

By weighing the advantages of orbital GMAW vs. GTAW, it is fair to say that both processes have their unique aspects. While GTAW is more complex and requires skilled personnel to handle the task, it produces a precise and quality result. But although you can be assured of quality, there is a compromise with productivity. GMAW is comparatively faster and more economical.

Orbital technology has, in many ways, minimized the disadvantages of the GTAW process. For instance, the productivity with GTAW has significantly increased due to the speed of automation and the decrease in waste. Similarly, orbital GTAW also helps produce uniform and repeatable results.

Orbital Welding Provides Quality and Productivity

The choice between MIG and TIG doesn’t have to be the choice between quality and speed. Orbital welding can improve the welding precision, speed, and efficiency, whether you are performing GMAW or GTAW. But you must understand the requirements for material, quality standards, and production needs before you make the decision. Many industries now use hybrid TIG-MIG welding to leverage the advantages of both, and manufacturers can always include orbital welding for even better results and cost-efficient operation.

Arc Machines, Inc has been a leading provider of orbital welding solutions providing quality and efficiency for industries making selections between GMAW vs. GTAW. For product inquiries, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. To develop a custom solution, contact us to arrange a meeting.