What factors do you prioritize when performing a weld? Most manufacturers seek high-quality results that meet industry standards while adhering to fixed time and cost constraints. Projects such as oil and gas pipelines, pressure vessel fabrication, and shipbuilding are time-sensitive, though, and achieving the priorities mentioned above with a manual process can be challenging. An automated process like orbital welding that utilizes high-quality orbital welding equipment can provide the solution.

Why Use Our Orbital Welding Equipment?

For high-specification pipe and tube applications, orbital welding has become integral to industries like aerospace, power generation, oil and gas, food and beverage, semiconductor, and biopharmaceuticals. And to achieve the highest quality of fusion with orbital welding, manufacturers must first consider factors like material selection, weld preparation, and the choice of the welding process. The next step is to select compatible orbital welding equipment.

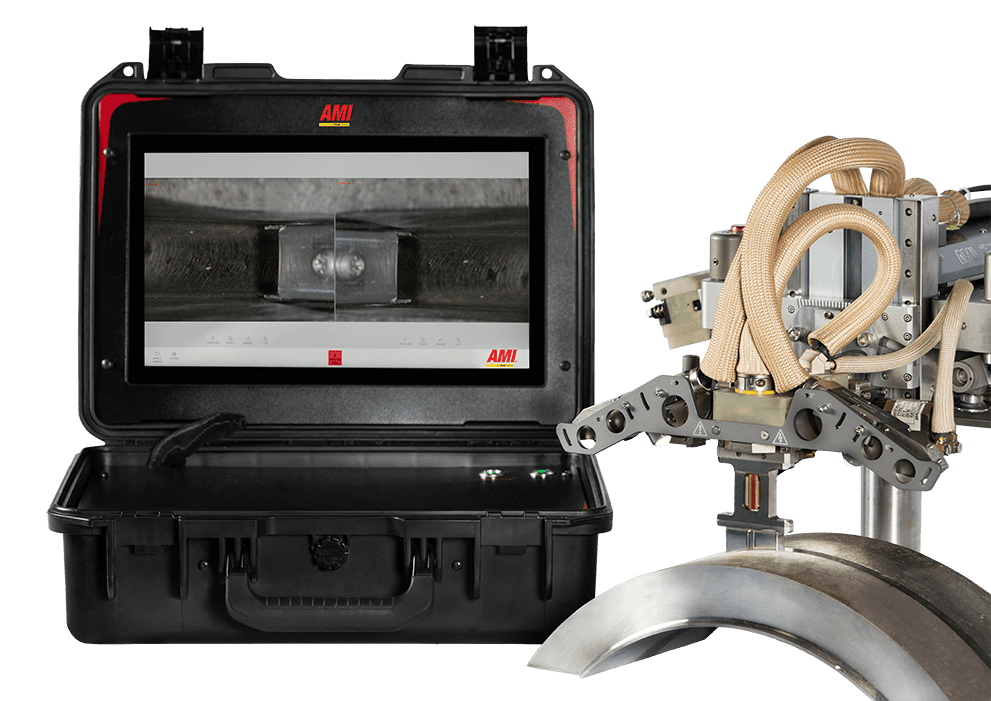

At AMI, we provide specialized orbital welding equipment and accessories that can fit your unique welding requirements. Our weld heads and power supply units are ideal for welding pipes, tubes, tube sheets, narrow grooves, or overlays.

AMI Weld Heads

Our open and closed weld heads can help manufacturers achieve ideal outcomes when welding pipes and tubes of different materials, thicknesses, and diameters. The weld heads operate automatically with the help of a guide ring clamped to the fixed workpiece. Their features include:

- Single or dual wire feed systems

- Clamping mechanisms

- Flexible extension cables

- Water-cooled housing

- Programmable arc voltage control, wire feed, and torch oscillation

AMI offers the following specialized pipe and tube weld heads.

AMI Power Supplies

The power supply units used in welding offer control over weld amperage, voltage, gas flow rate, wire feed, oscillation, and other weld parameters. Our modern power supplies provide the following features to support orbital welding accuracy and precision–

- Weld schedule programming

- Advanced orbital analytics

- Compatible with a wide range of fusion weld heads

AMI provides the following power supply solutions with advanced control and an efficient user interface for welders:

Orbital Welding Accessories

In addition to the equipment directly responsible for the weld, a high-quality weld process requires supporting accessories to help weld heads and power supply units achieve optimal accuracy. Such accessories may include mounting tracks for welding the exterior of the pipe, a cooling unit for temperature control of weld heads, purge dams to seal the pipe ends, and oxygen sensors to monitor oxygen levels when pipe welding. AMI provides a range of such accessories to meet the needs of your application, including:

AMI’s Solution to Your High-Quality Welding Needs

From small tubing projects to large-scale oil and gas pipeline installations, a reliable welding solution is essential. You can rely on high-quality orbital welding equipment and accessories from AMI to meet your application requirements. Or, if you require a custom welding solution with a specialized mounting system or other adaptations, we can help. Trust AMI to provide high-quality results that will meet your industrial standards and productivity goals.

READY TO CONNECT?

Arc Machines, Inc., a leading provider of orbital welding equipment and accessories, can help you achieve high-quality welds for your standard or custom weld applications. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Contact us to arrange a meeting. Arc Machines welcomes the opportunity to discuss and assist you in meeting your specific needs.