In the U.S., the Occupational Safety and Health Administration (OSHA) is the source of many rules and guidelines intended to protect workers from job-related hazards across virtually all industries. Some of the rules apply to dangerous jobs like hot work—such as welding and cutting—required for activities as diverse as bio-pharmacy, food production, nuclear power generation, and aviation. For these applications, misinterpretation of the rules can result in ineffective prevention and mitigation policies; for welding hazards, this is unacceptable.

Let’s take a look at some of the most important OSHA hot work standards and how to ensure that these rules are followed correctly.

OSHA Hot Work Standards You Should Know

OSHA generally defines hot work as follows:

Hot work is any work that involves burning, welding, cutting, brazing, soldering, grinding, using fire- or spark-producing tools, or other work that produces a source of ignition. Welding and cutting operations are common to drilling and servicing operations.

As stipulated, welding and cutting operations are major hot work processes, as they can be sources of ignition. Therefore, specific OSHA safety requirements target these occupational processes. Some of the most important to know are listed below.

| IMPORTANT OSHA HOT WORK STANDARDS |

| OSHA Standard | Description | Intent |

CFR 1910Subpart I Subpart Q Subpart Z | Nonmandatory Compliance Guidelines for Hazard Assessment and Personal Protective Equipment Selection Welding, Cutting, and Brazing Toxic and Hazardous Substances | To ensure that personnel takes steps to protect themselves by wearing PPE. To provide guidance on the testing and utilization of shielded gas regulators and instructions on how to safely use electrical welding equipment in non-permit confined spaces. To provide guidance on which substances are hazardous and how to ensure they do not exceed established compliance levels. |

| CFR 1915Subpart D Subpart I Subpart P Subpart Z | Welding, Cutting, and Heating Personal Protective Equipment (PPE) Fire Protection in Shipyard Employment Toxic and Hazardous Substances | To provide guidance about fissionable materials and ventilation when doing welding, cutting, and heating. To provide guidance on types of PPE that should be used by shipyard employees. To provide guidelines for a fire plan, fire watch, and fire response when hot work is being performed. To provide information about what substances used in hot work may be toxic. |

| CFR 1917Subpart G | Related Terminal Operations and Equipment | To ensure that steps are taken to prevent fire when working with compressed air equipment. |

| CFR 1926Subpart J Subpart Z | Welding and Cutting Toxic and Hazardous Substances | To provide information and guidance about ventilation procedures while performing gas and arc welding and cutting to avoid fires. To provide information about which substances are toxic and how to handle them to prevent contingency. |

The list of OSHA hot work standards is not exhaustive; however, it does adequately convey the importance with which this issue is addressed by the agency. Therefore, it is also important that you incorporate OSHA compliance into your hot work projects.

Ensuring Your Hot Work Meets OSHA Standards

When using welding equipment—whether to join or cut materials—safety considerations should be paramount. OSHA hot work standards are meant to codify these safety concerns. The same intent to ensure welding safety should guide your operations.

Guidelines for Satisfying OSHA Hot Work Standards

- Know and understand the pertinent standards

- Adopt a workflow culture based on OSHA standard compliance

- Implement process(es) that help facilitate standard compliance

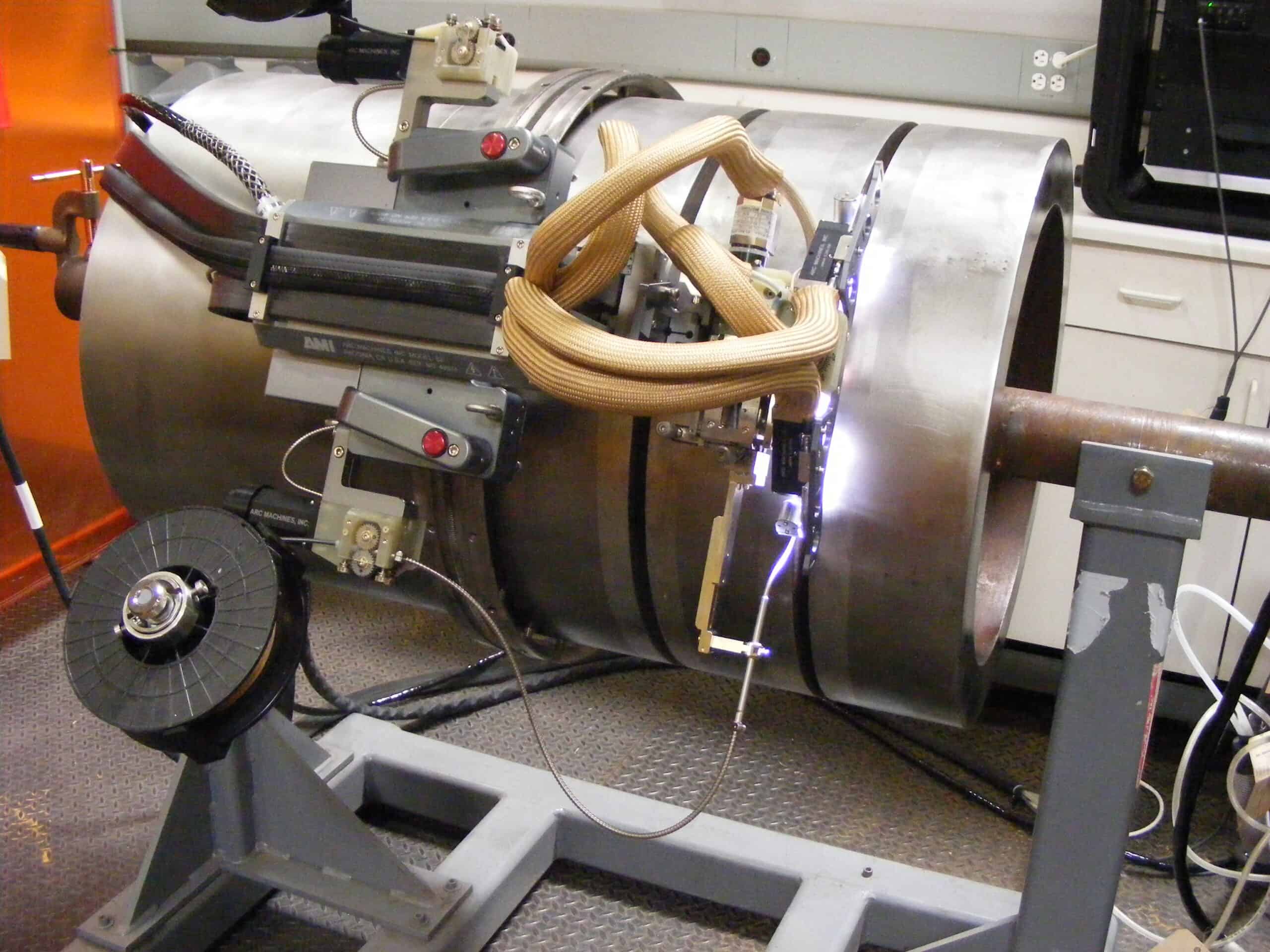

One of the best ways to achieve compliance and reflect the intent of the hot work standards established by OSHA is to employ an orbital welding process.

How Orbital Welding Supports OSHA Hot Work Standards

There are many projects where orbital welding is the best option for hot work. Not only does orbital TIG welding provide the highest quality welds due to its consistency, but this automated process also improves safety for the operator and minimizes the possibility of any out-of-control ignition or fire contingencies.

Arc Machines, Inc. is an industry leader in supplying advanced and high-quality welding equipment and service. This includes orbital welding machines, materials, and expertise to aid in your compliance with OSHA hot work standards. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.