Many fluid systems prefer tubings instead of pipes for a smoother and more controlled flow of fluid with less drag coefficient. These systems also use tubes to reduce the potential leak points in a highly pressurized system by replacing the need for multiple fittings. Considering their diverse uses, tubes have been crucial in fluid flow applications. The same applies to the orbital welding technique for creating high-quality welded tubes.

The quality of a good tube is determined by its strength, smoothness, and lack of defects. In industries such as petrochemical, biopharmaceutical, or semiconductor, these qualities support the provision for ideal process conditions and sanitary requirements. The correct welding tools and techniques are key to achieving the optimal qualities in a welded tube. Let us explore the role orbital tube welding equipment can play in fabricating quality tubes while maintaining productivity.

Tube Welding Requirements

Although there are similarities in principle, tube welding differs from pipe welding in practice.

- Tubes are thin-walled so that they can be welded in a single pass. This contrasts with thick-walled pipes that require multiple passes.

- Since the tubes are thin, they are more prone to distortion and warping without controlled heat input.

- Tube welding requires adherence to a much stricter tolerance than when welding pipes.

Tubes are also a significant part of components like boilers, condensers, or steam generators, where tube-to-tubesheet welding comes into play. Multiple tubes may be required to be attached to the tubesheet in a tight workspace without much clearance. Orbital welding can quickly address these requirements while fabricating precise, seamless tube welds.

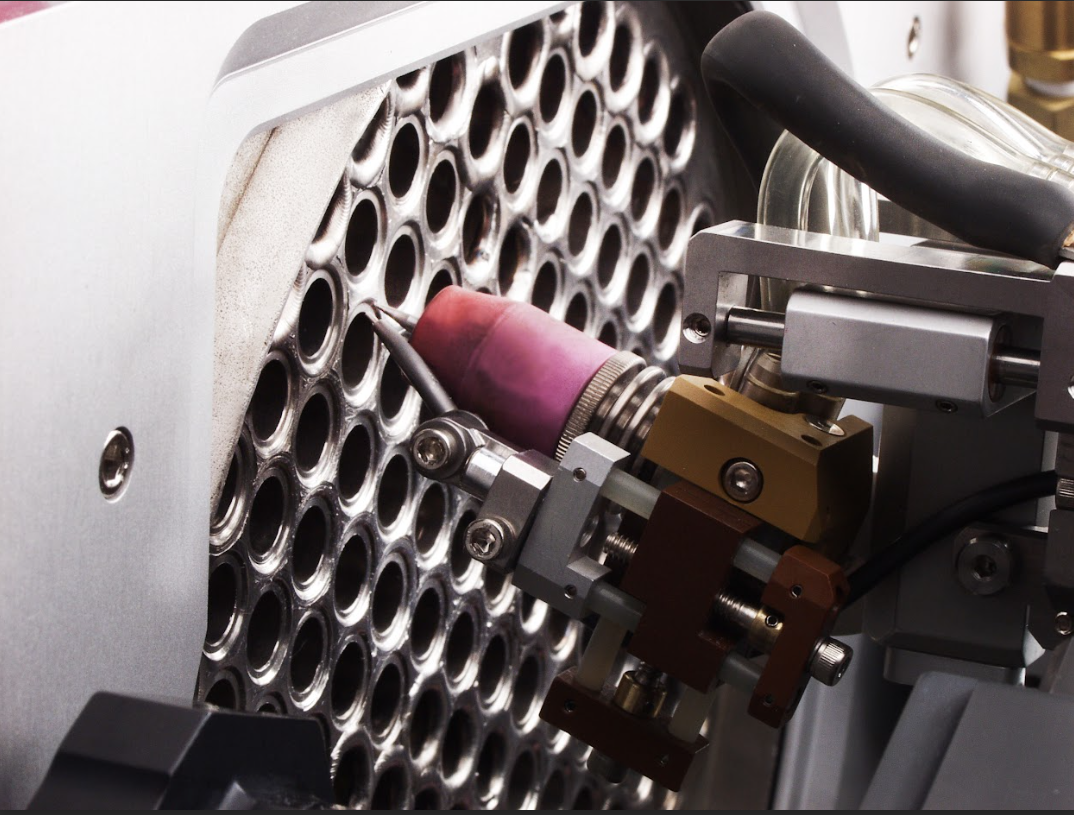

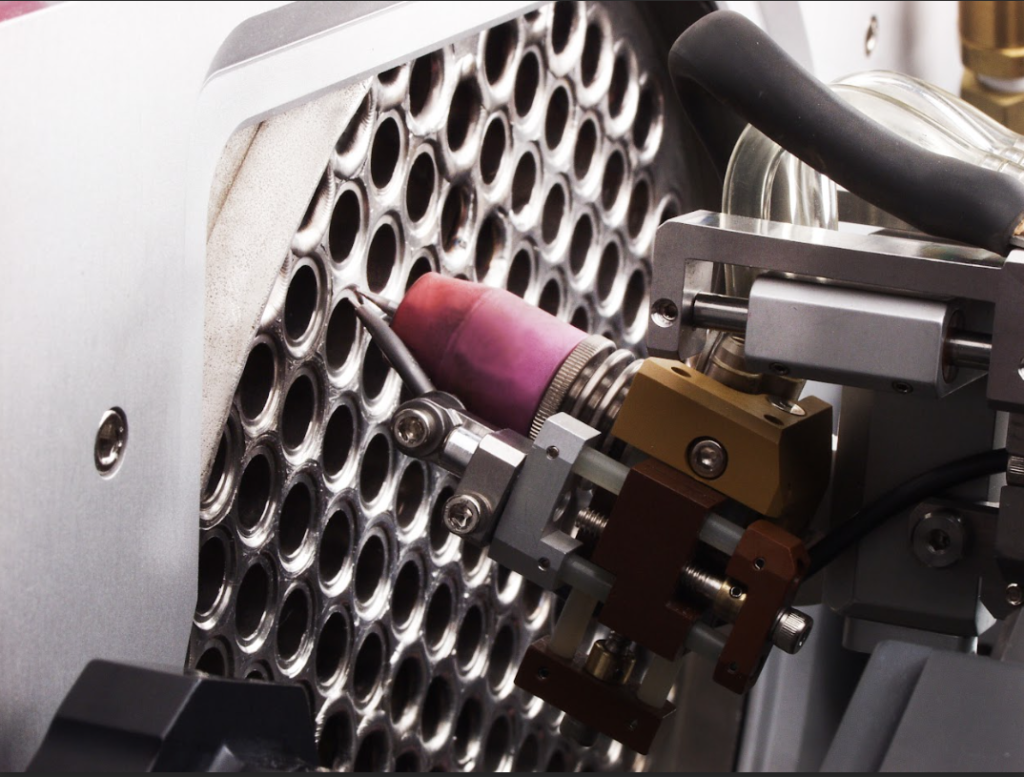

Automatic tube welders can be set up with specialized orbital tube welding equipment, such as the closed weld head or tube-to-tubesheet weld heads and highly efficient power supplies. With extensive machine setup, equipment calibration, and weld parameter optimization, tube welding can operate at a push of a button to generate high-quality and consistent results.

AMI’s Orbital Tube Welding Solutions

AMI offers a wide range of orbital tube welding equipment compatible with tubes of different materials and thicknesses. These include –

- Model 4-500 Bench-Top Weld Head

- Model 7-500 Weld Head

- Model 6 Weld Head

- Model 96 Series Weld Head

- Model 8 Series Weld Head

- Model 9 Series Weld Head

- Model 217 Power Supply

Extending the Use of Your Orbital Tube Welding Equipment

As mentioned above, the complication of welding increases substantially when welding tubes to tubesheets. With tubes in close proximity to each other, access can be limited, especially if the weld has to be revisited. To add to the challenge, most tubes and tube sheets in critical sanitary applications are made of stainless steel, which can generate potentially hazardous gas when welding, like hexavalent chromium.

As a solution, some orbital tube welding equipment is designed to improve compatibility with robotic systems. AMI’s robotic welding systems, such as the M60/M60R/M23 weld head, can be attached to the robotic arm to extend its reach and flexibility. The advantages of using such robotic systems when tube welding include–

- The weld head can reach complicated spots

- Revisiting defective welds is easier

- Robots help to prevent trips and falls and limits welders’ exposure to toxic gasses

- Automated robots improve welding quality and productivity

Precision Welding With Orbital Tube Welding Equipment

Tubes in critical fluid systems have to face high-stress, high-pressure, and high-temperature conditions. This demands high strength, corrosion resistance, and leak-free welded tubes. Quality orbital tube welding equipment will help you fabricate a tube with high precision and accuracy. In addition, specialized tube and tube-to-tubesheet weld heads and power supplies facilitate welding in the difficult-to-access areas, while the robotic system further streamlines the process. With welding equipment that allows easy accessibility, process control, and precision welding, the resulting tube system will likely have a long and productive lifespan.

Arc Machines, Inc. provides high-quality orbital tube welding equipment for tube and tube-to-tubesheet welding. To learn more, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Contact us to arrange a meeting. Arc Machines welcomes the opportunity to discuss your specific needs.