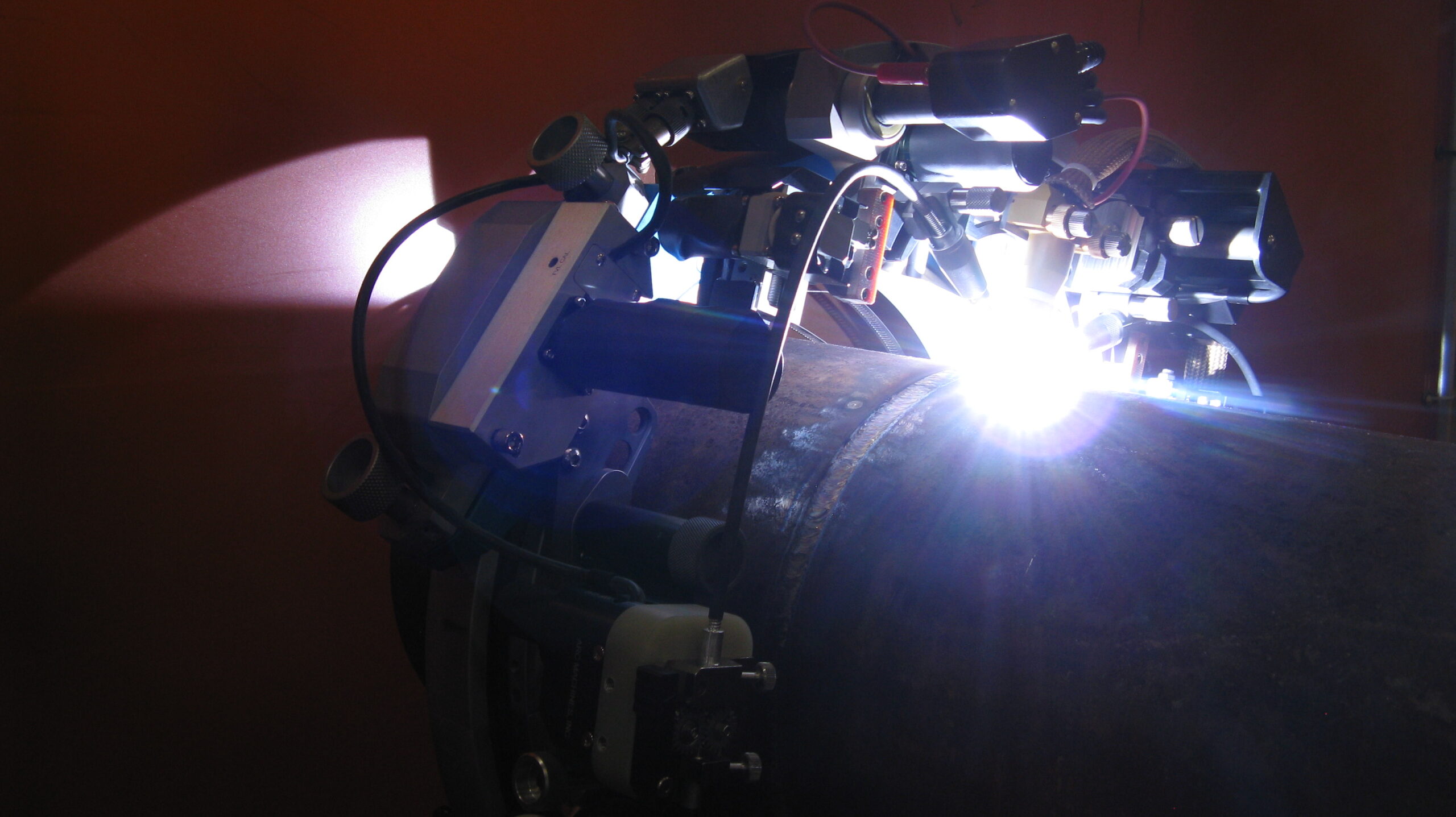

How do you determine the quality and integrity of the weld? Is it based on the size and appearance of the weld or the number of defects? These are critical questions the welders should ask when performing a weld. And the first approach to getting them answered is through visual…