Heat exchangers are exactly what they are called: devices that transfer heat from one medium to another and heat exchangers find wide use in power generation and other industries. Tubesheets are simply sheets of metal perforated with holes that metal tubes can pass through at either end of a heat…

The history of pipe and tube production dates back to the 1900s when a process like hot-rolling was used for large-scale manufacturing. Since then, technologies like welding and seamless manufacturing have allowed the production of a much larger scale of pipes and tubes. Welding accounts for over half of all…

Thin or thick sections, steel or aluminum, TIG welding can join it all. And the fusion ability is not just limited to the material with closely-related properties, but it also extends to dissimilar metals. Creating a reliable bond when the properties of two materials differ drastically is challenging, but much…

Welding in confined spaces is likely to be a familiar, if unpleasant, task for most welders. It can sometimes seem like most welding work needs to be done in an unairconditioned, unventilated broom closet and done to an object that can only be reached through a foot-by-foot hole in the…

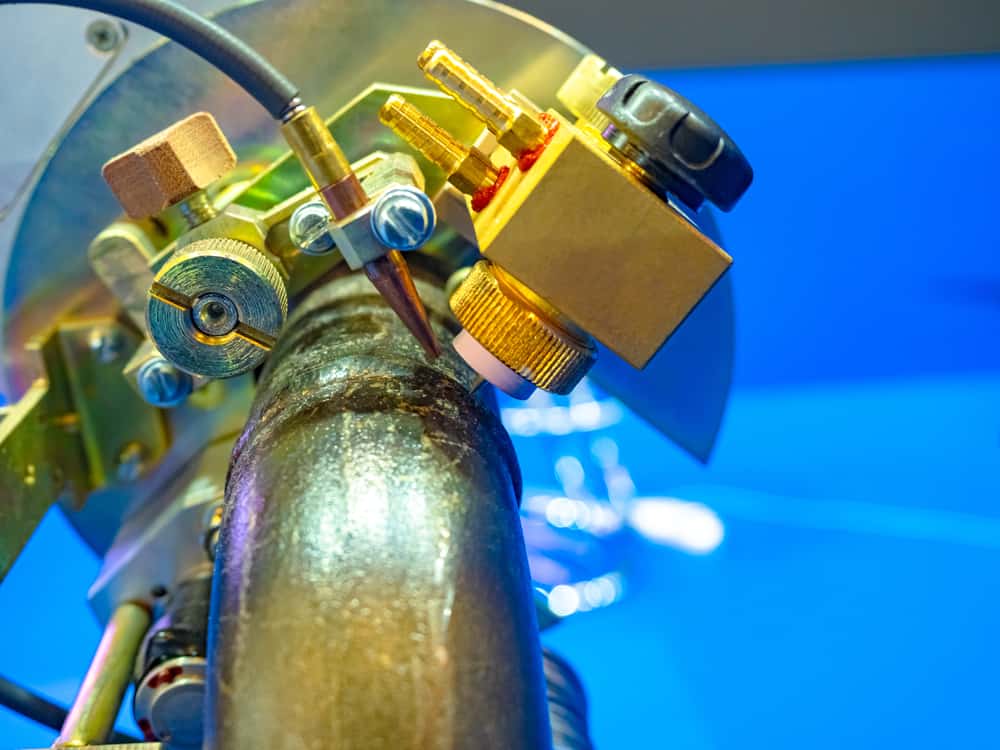

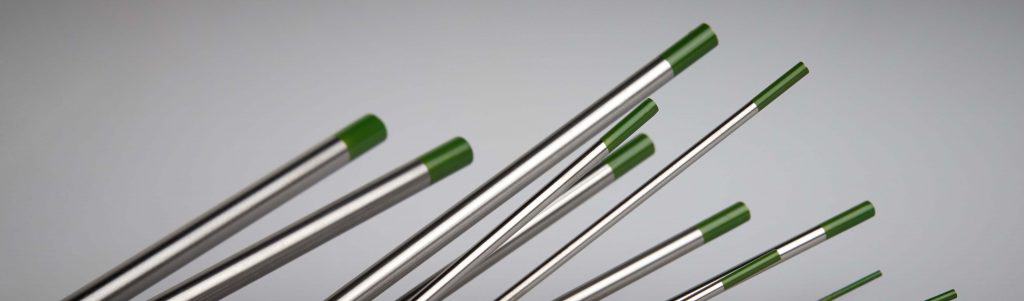

The most popular arc welding processes are GMAW and GTAW. The GMAW process is faster; however, GTAW or TIG welding produces higher quality welds. For many industries; such as aerospace, the bar for quality welding requires the process be optimized. Meeting this demand begins with choosing the best materials. Therefore,…

In all industries with high-purity requirements, you will observe one thing in common — stainless steel pipes and tubings. The smooth finish and corrosion-resistant features have been ideal for avoiding contamination due to rusting, bacterial growth, or chemical mix-up. The metal is also heat and impact resistant, providing the required…