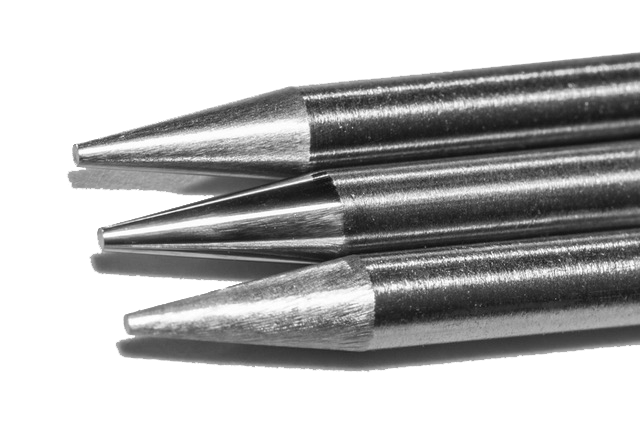

The long-time standard for welding pipes is shielded metal arc welding (SMAW), commonly called “stick” because of the rod-shaped consumable electrodes used. SMAW has been one of the most widely used forms of arc welding for decades. Qualified welders and SMAW equipment are widely available and this process is simple…