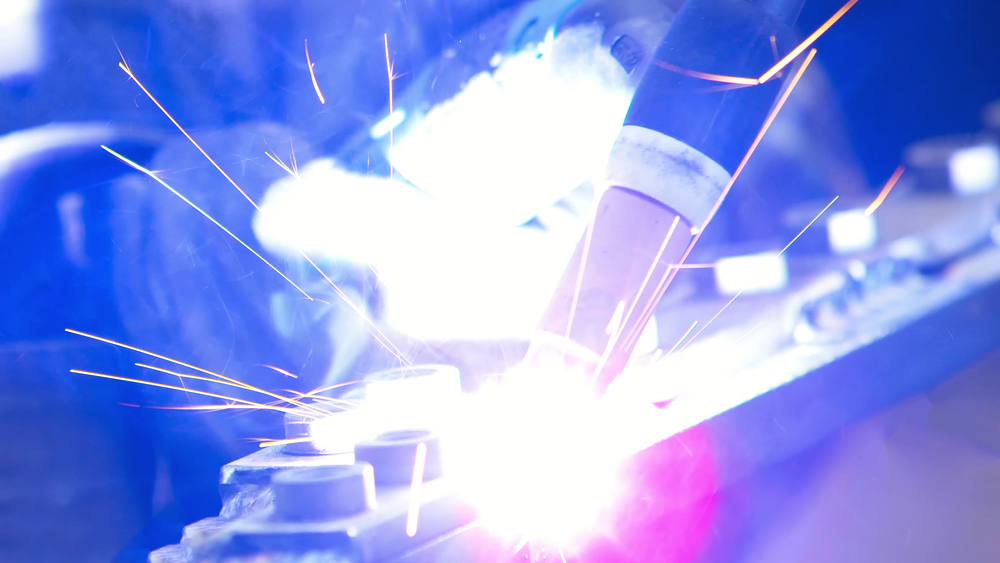

The core of gas tungsten arc welding (GTAW) is obviously the tungsten. A great deal of attention is paid to the different tungsten electrode types. Even something as seemingly minor as the tungsten grind angle can have an outsized impact on the final weld. However, the torch which holds the tungsten is an equally critical element, and the qualities of GTAW torch parts used, whether the torch is an automated orbital design or a manual one, these elements can have a dramatic impact on the quality of the weld that is produced. It also has implications for setup before welding begins and how easily maintained GTAW torches are.

Whether a GTAW process is automated or manual, or a torch is air or liquid cooled, there are commonalities in the GTAW torch parts that are used. Understanding what these individual parts do can help troubleshoot maintenance issues with welding setups and in determining where problems in welding are coming from.

GTAW Torch Parts: Collets and Collet Bodies With Gas Lenses

GTAW torches are, in a very literal sense, built around the tungsten. Although tungsten electrodes are nonconsumable, they do degrade with repeated use. In manual GTAW, crashing the tungsten against the weld and having to regrind both it and the weld isn’t that uncommon. This means that torches and GTAW torch parts are designed so that the tungsten can be removed, replaced, and then the entire torch reassembled around it. The common parts of a GTAW torch, starting from the tungsten and working out, are:

| Part | Description |

|---|---|

| Collet | The collet directly holds the tungsten electrode, and its role is to hold it firmly in place and simultaneously make a firm electrical connection with it. This is most commonly accomplished by a back cap that holds the collet into position and squeezes it tightly against the tungsten as it is tightened. |

| Collet Body | A collet body is a threaded electrically conductive piece forward of the collet that helps position the collet and the electrode it contains. It also transfers electrical current to the collet. |

| Gas Lens | A gas lens is typically fixed forward of the collet body. This is usually a series of fine stainless steel meshes that convert the shielding gas flow into a column of gas rather than a turbulent column that can draw external atmosphere into the mix and contaminate the weld. A GTAW gas flow rate that is too high or low can prevent the gas lens from doing its job. |

| Nozzle/Gas Cup | The most identifiable part of a GTAW torch is the typically reddish or pink gas cup. This generally is a ceramic or ceramic-covered metal part that focuses the gas flow around the tungsten and keeps the molten metal surrounded by shielding gas. The exit diameter of the nozzle must be correctly sized as if they are too large, the gas will be easily blown away, and if they are too small, they will fail to cover the welded area. |

These GTAW torch parts are common across most types of GTAW welding machines, with the differences being in how these elements are adapted to different roles. Narrow groove GTAW is meant for big bore pipe welding and similarly heavy-duty tasks which require a lot of heat and steady current flow. Narrow groove tungsten electrodes incorporate what is effectively a collet into the electrode itself to ensure an even flow of current and heat into the electrode to help keep the arc and weld fusion symmetrical. Other heavy-duty GTAW torches are water-cooled to deal with excess heat. This is accomplished by modifying the collet body into a coolant sleeve that transfers heat from the collet and the tungsten it contains. Although somewhat unnervingly, these modified collet bodies retain their job of ensuring the collet receives enough current and frequently use the same lead for the current input and the coolant outflow or inflow.

The key takeaway from these GTAW torch parts is their commonality of function between different types of GTAW torches. This includes automated or semi-automated GTAW torch parts. However, these parts’ size, position, and functionality can be substantially altered. Although very different, they are still recognizable and performing what are recognizably the same roles they usually do.

Orbital Weld Head GTAW Torch Parts

One of the most surprising things to welders who have performed manual GTAW welding is how recognizable the components of most automated orbital GTAW weld heads are. Ceramic nozzles are prominent features of most of these weld head types. The exception is closed weld heads used in autogenous welding. This is because the body of the weld head effectively acts as a gas nozzle that surrounds the workpiece and the joint with shielding gas. The other familiar GTAW torch parts are still present and still recognizable.

In larger models meant for interior diameter welding or cladding, things are even more immediately recognizable as GTAW torch parts are mounted in an unusual configuration on machinery that allows them to be mobile and operate as directed via a weld parameter that is input through a power supply. This illustrates what is most likely the most significant difference between GTAW torch parts made for manual welding and those meant for automated processes. Automated GTAW torch parts like those meant for orbital welding are part of an integrated system. So while an operator can switch out all manual GTAW torch parts on a whim, automated or semi-automated systems like orbital welders need to account for these differences in the welding parameters, and need to use GTAW torch parts from the manufacturer to ensure their suitability.

Arc Machines Inc. is a leader in orbital welding equipment with a long history of providing tough and reliable open and closed weld heads, and the GTAW torch parts needed to keep them operating smoothly and reliably to improve welding productivity and quality.

Contact us to find out more about orbital welding parameters and GTAW torch parts for your Arc Machines. To learn more about our products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines looks forward to providing the equipment and services your project needs.