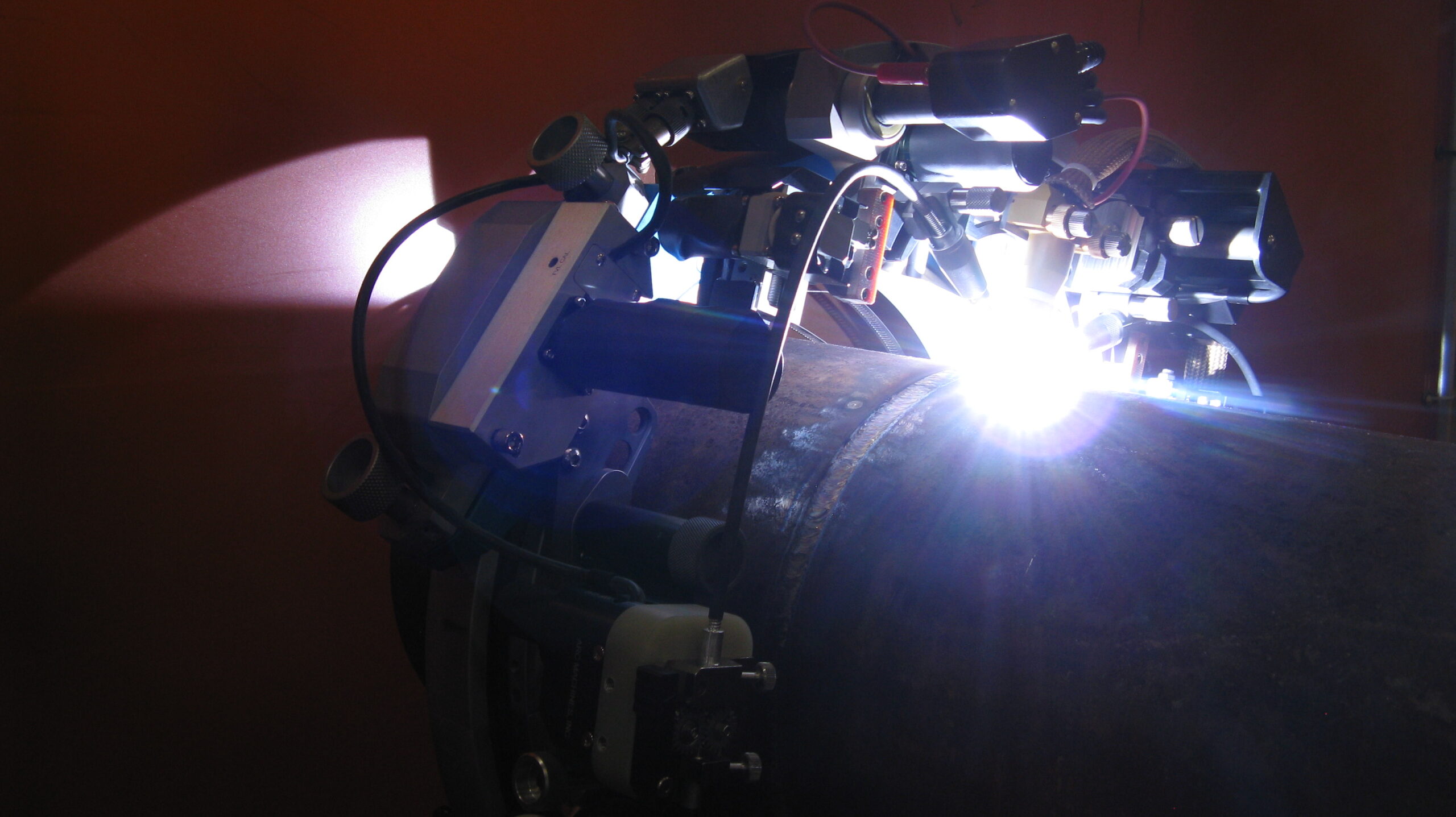

Fillet welding a pipe can add complexity to the joint, but comes with its own demands. The most obvious one is the challenge to achieve complete fusion while maintaining the perpendicular angle. To ensure that the fillet welds around a pipe will result in a high-quality and strong joint, we…