Shielded Metal Arc Welding (SMAW), also known as stick, is generally the default welding process for pipe. A simple internet search for pipe welding yields countless images of welders using this process along with many tutorials on how to weld pipe correctly using stick welding. However, in spite of its wide use, SMAW is probably not the best way to weld pipe. It is merely the welding process that has been used to weld pipe the longest.

Since the development of SMAW, several other arc welding processes have emerged and have gained widespread use. Wire feed arc welding processes like Gas Metal Arc Welding (GMAW) and Flux Core Arc Welding (FCAW) are significantly easier to perform than traditional stick welding. Gas Tungsten Arc Welding (GTAW) requires a great deal of skill to use, but produces cleaner, more precise, and more reliable welds that last longer and resist corrosives and high pressure better than welds made using other processes. Does this make GTAW the best way to weld pipe? That depends.

Which Welding Process Creates the Best Welds?

Which welding process offers the best method of welding pipe depends on what qualities of the welding process are considered most critical for a given project. For instance, if speed matters most, a project manager might consider FCAW to be the best. The principles involved in FCAW are essentially the same as SMAW, but in FCAW the flux is provided by the core of the wire electrode. Due to the use of a continuously fed wire electrode, the process is quick, and thanks to the flux, it’s also easy to use and forgiving of less-than-perfect surrounding environments. However, the welds that it produces are not perfect. For a higher quality weld, it’s necessary to choose a welding process that uses gas shielding.

GMAW and GTAW arc welding both use inert gas to shield the weld during the welding process. The use of this gas results in a more consistent, predictable, and reliable weld than processes using flux. While the use of shielding gas means that the process isn’t ideal for fieldwork—wind can easily blow the gas away—the quality of the welds produced using these processes has led to some projects using special barriers or even erecting full structures to enable the use of gas-shielded welding processes. While GMAW beats GTAW in terms of speed, the GTAW process has some major advantages, which we’ll talk about below.

GTAW Welding Provides the Most Consistent, Clean, and Reliable Welds

Gas Tungsten Arc Welding (GTAW) differs from other gas-shielded welding processes in that it uses a non-consumable tungsten electrode. The tip of the tungsten electrode used in GTAW welding must also be carefully ground to the correct shape, which will vary depending on the type of metal being welded. Shielding gas flows around the tungsten, and when an arc is struck, the electrode makes a very small molten puddle that remains pure and can be directed with an incredible degree of fine control.

In the hands of a skilled arc welder, GTAW welding creates very neat, precise, and reliable welds. The advantages of GTAW pipe welding include:

- Versatility: It can weld ferrous and non-ferrous metals equally well. The GTAW process also does an excellent job welding exotic metals and alloys like titanium, Inconel®, Monel®, and other specialty application alloys. It can be used on very thin metals that SMAW, FCAW, or GMAW would burn through and can be used to perform either autogenous welds or welds requiring filler material.

- Quality: When performed correctly, GTAW produces incredibly clean welds without slag or spatter. GTAW welds also are far less prone to the inclusion of contaminants like hydrogen and oxygen or incidental inclusions like carbon and other metals. High-quality welds like these are especially important in pipe welding projects as piping is frequently pressurized.

- Reliability: The consistency, quality, and cleanliness of GTAW welding mean that the welds produced are far more mechanically consistent than welds made using other methods. As a result, GTAW welds have fewer weak spots and are more able to resist lateral loading, compression, and internal pressures. The neatness of the weld surface also offers far fewer opportunities for chemical corrosion, which is important for pipe projects that may involve conveying corrosive gases and fluids.

The advantages of GTAW arc welding make it the best way to weld pipe for those seeking quality welds. Unfortunately, the manual GTAW welding process has several disadvantages. It is difficult to master this welding process and it takes a great deal of training and experience before a welder can correctly weld GTAW. It is also a very slow process, and, as a result, manually performing deep groove or narrow groove pipe welds takes a prohibitive amount of time. Usually, if manual GTAW is used weld pipe, it is only used for the root pass—the part of the weld in actual contact with the pressurized or corrosive material in the pipe—while the rest of the groove is filled in using FCAW, GMAW, or even SMAW processes. However, developments in automation have solved many of the disadvantages of GTAW by making it possible to perform reliable GTAW welds using orbital welding.

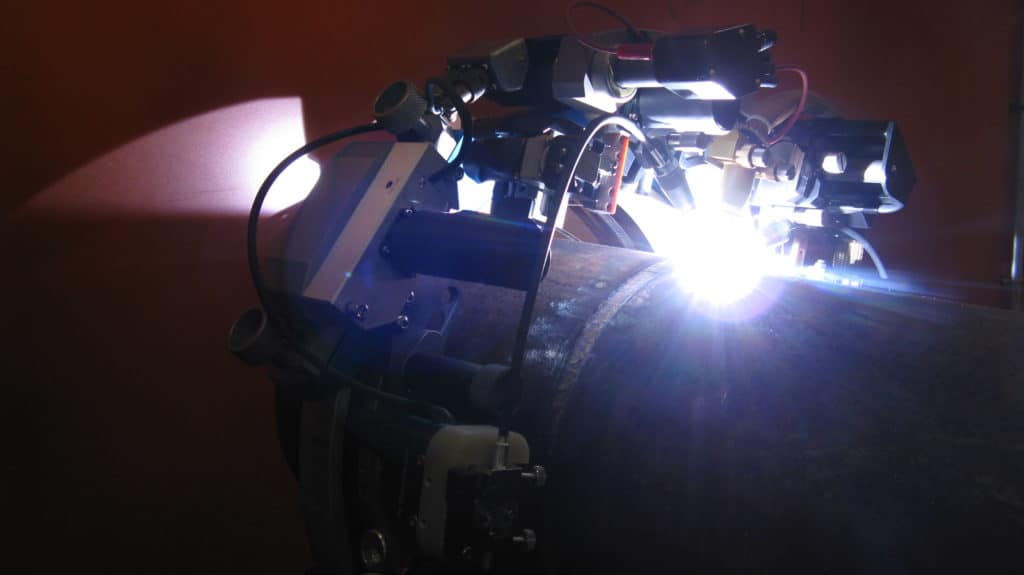

Why Automated Orbital GTAW Is the Best Way to Weld Pipe

Orbital welding is a mechanized welding process that allows the welder to program the weld controller with the weld parameters, such as the feed rate of filler material, travel speed, weld current, arc voltage, and other variables. By automating the weld procedure, orbital GTAW welding makes the process easier for the operator and provides a solution to the problem of finding qualified GTAW welders.

Automated orbital welders can be continuously wire-fed as well as autogenous. Wire feeds significantly speed up the orbital GTAW welding process for narrow groove welds and other weld types that require a great deal of filler material. Automated GTAW welding can improve welding productivity for both thick-walled pipe and pipe welding where no filler is required. Orbital GTAW machines produce high-quality welds more easily and efficiently than manual GTAW, making automated orbital GTAW welding the best way to weld pipe.

Arc Machines, Inc. leads the industry in GTAW orbital welding systems, offering the products you need to perform top-quality pipe welds for demanding petrochemical, manufacturing, and other industrial projects. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.