Welding in the overhead position—with the workpiece directly above the welder—is widely thought to be the most difficult welding position. Pipe welding is also well known to be particularly challenging welding work. The perception that both are especially difficult types of welding is born out by the fact that each type has its own welding certification. A 4G certification signifies that a welder can produce satisfactory overhead welds, while a 5G certification indicates that the welder has welded a pipe joint that has passed testing. The truth is that welding pipe is difficult because it involves every welding position—including overhead—and the welder must be able to weld in all of these positions with equal facility, repeatedly, to make a single satisfactory weld. In this article, we’ll discuss a few of the other challenges of overhead pipe welding and look at ways to eliminate those issues, including through the use of orbital welding.

The Challenges of Overhead Welding

Overhead welding is probably the most disliked manual welding position. Trying to work with one’s hands above the head (and in some cases while laying on your back) isn’t easy in the best of circumstances. Doing so while it rains red hot metal requires determination. The welder must fight the force of gravity unfailingly through fatigue and burns in order to produce a quality weld that will hold up to both internal pressure and external forces—and must maintain this consistency through several passes to complete a joint.

Some of the more unpleasant drawbacks of manual overhead welding include:

- The sleeves and collar of the welder’s personal protective equipment (PPE) are oriented directly towards the weld. Sparks from welding often bypass protective equipment and cause numerous small burns to the forearms and torso.

- If the welder moves too quickly or too slowly, the molten metal can fail to properly fuse. Molten metal can fall partly out of the weld, forming an obvious flaw. Large globules can even fall directly onto the welder or into their PPE.

- Molten metal falling from the weld increases the likelihood of fires. Sparks and molten metal are excellent ignition sources and welding in the overhead position means that gravity allows more of them to fall free of the weld. Often what they ignite is the welder’s clothing or their PPE.

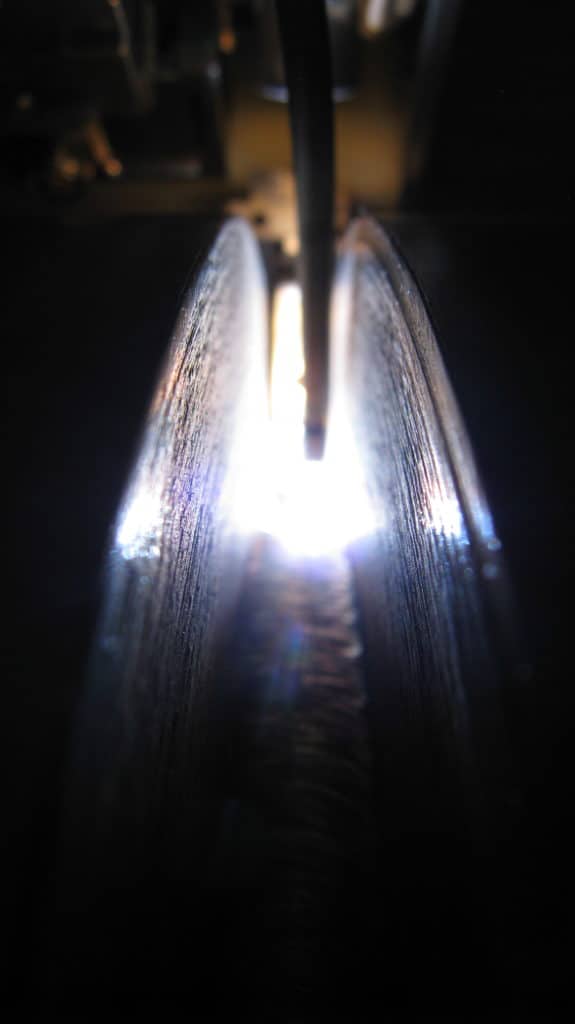

The drawbacks listed above tend to be exacerbated by the nature of most overhead welds. Often, the puddle wants to flow with gravity out of the weld, and getting it to stay in place requires an extra level of skill to keep the puddle at the base or face of the joint where it should be. Many overhead welds are deep groove welds—the G in 4G welding refers to groove—that require multiple passes to complete. Fatigue in later passes is a genuine issue. When a welder’s arms become tired from holding the electrode, it can be difficult to keep the arc length steady, which affects weld quality and consistency. In GTAW welding, the hand feeding fill material into the molten puddle also grows tired, and this leads to the collision of the tungsten and the filler rod, meaning that work must stop in order to change out or regrind the tungsten—this opens up more opportunities for flaws in the weld. And any mistakes made during a deep groove welding process can exacerbate welder fatigue. That’s because any flaw in the weld requires that a great deal of metal be removed before the welds can be redone and this work is also very tiring to do in the overhead position.

Pipe welding, as well, has its own challenges. The shape of a pipe means the welder must change angles and position as they work around the circumference of a pipe, and at least two of those positions require overhead welding.

The Unique Challenges of Manual Pipe Welding

Manually welding pipe requires the use of every welding position in order to create a consistent weld around the full circumference of the pipe. The welder divides the pipe’s circumference into quarters, and welds one quarter at a time, stopping between each quarter to reposition themselves.

Transitioning between positions during the weld makes maintaining the correct pattern, angle, and travel speed more difficult. When a welder chooses a new position, they try to find one that allows them a wide range of motion while enabling them to brace themselves so that they aren’t forced to hold steady purely through muscle tension.

The type of location where piping is most often installed adds another wrinkle to the tricky process of manual pipe welding. Pipes tend to be located either close to the ground or near the ceiling. Overhead pipe welding often involves arc welding in a tight, awkward space below the pipe or standing on a ladder reaching up. This makes the transition between vertical and overhead pipe welding positions even more difficult to manage. Fortunately, automated orbital welding successfully eliminates all of these challenges posed by welding pipe in the overhead position.

How Orbital Welding Simplifies Overhead Pipe Welding

One of the most obvious benefits that mechanized welding processes offer is to remove the welder from the fall line of the molten metal. Even semi-automated orbital welding, in which the welder operates a weld head using a remote pendant, allows the welder far more leeway in choosing their position than manual welding does.

Orbital pipe welding also removes the many opportunities for flaws to form in the weld. Sectioning a weld into quarters means starting and stopping, and each start and stop is an opportunity for foreign materials to enter the weld. If the welder makes a mistake when striking an arc, for example, this could disrupt the shielding gas and include contaminants into the weld. In fact, the more times an arc must be struck, the more likely an inclusion is, and when a pipe weld that requires multiple passes is quartered, the arc needs to be struck many times.

Orbital welding, by comparison, can make each pass in a continuous circuit around the full circumference of the pipe, removing many of the opportunities for contaminants to enter the weld. Since orbital welding weld heads either clamp around a pipe or mount to it using a guide ring, the torch maintains a consistent travel speed and distance from the weld around the entire pipe.

Automated orbital welding simply puts many of the most challenging parts of the pipe welding process under the guidance of a programmed welding controller. This can be especially helpful in the case of overhead pipe welding, where the need to reach, position for, and maintain consistency throughout all welding positions requires not just skill, but also endurance. Using automated orbital welding to weld pipe overhead also makes it possible to efficiently and precisely weld pipe located in difficult or almost inaccessible positions, such as far overhead or close to the ground. Automated orbital pipe welding is the best way to consistently and reliably produce quality pipe welds in any position.

Arc Machines, Inc. orbital welding products produce reliable welds on almost any pipe. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.