Inconel® is an austenitic alloy of nickel and chrome with some valuable properties: it is very strong and resists both heat and corrosion. It’s also very expensive; six feet of Inconel 600 one-inch diameter tubing sells for $1,700 compared to $68 for an equivalent length of 304 stainless steel tubing. Given the properties of Inconel and its expense, it is safe to say that any use of the metal is very likely an important one where the needs justify the cost. In the demanding industries in which Inconel is used, such as nuclear and aerospace, a leak in an Inconel pipe or vessel isn’t just a leak—it’s all but certain to be a headline-making catastrophe.

For this reason, the best way to weld Inconel is gas tungsten arc welding (GTAW), the arc welding process that most reliably creates welds to demanding specifications. GTAW is also widely acknowledged as the best way to weld Monel®, another trademarked nickel alloy. For almost every use case, GTAW is the best method for welding Inconel, and, in fact, most metals.

The Properties and Varieties of Inconel

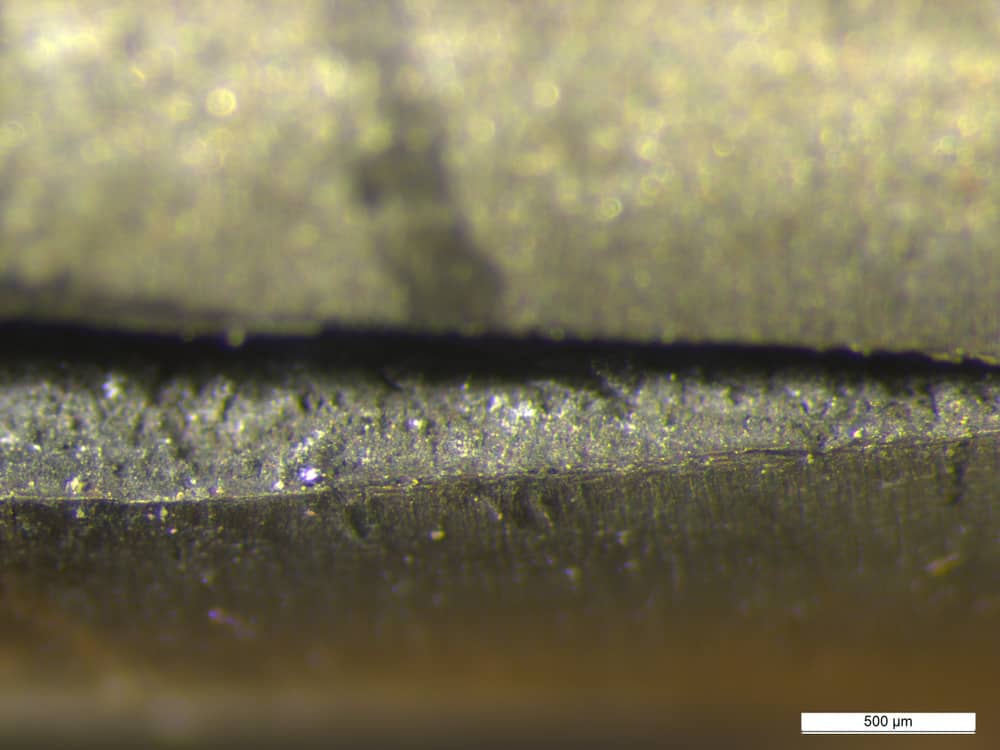

Compared to more common mild steel or stainless steels, molten Inconel® is very viscous. Welders liken welding with Inconel to pushing around a wad of bubblegum. When allowed to cool too quickly, the final segments of the weld often crack, forming a star-shaped fracture pattern. Surface oxidation on an Inconel weld is heavy, but can be readily removed when it is still warm after welding; it is considerably harder to remove after it has been allowed to cool.

It should be noted that Inconel isn’t a single alloy type. There are a wide variety of different Inconel alloys whose exact compositions and precise properties vary when welded. A chart of some of the most commonly used varieties and their exact compositions can be found below.

| Trade Name | Inconel 600 | Inconel 617 | Inconel 625 | Inconel 690 | Nuclear Grade 690 | Inconel 718 | Inconel X-750 |

| Nickel | ≥72% | 44.2-61% | ≥58% | ≥58% | ≥58% | 50-55% | ≥70% |

| Chromium | 14-17% | 20-24% | 20-23% | 27-31% | 28-31% | 17-21% | 14-17% |

| Iron | 6-10% | ≤3% | ≤3% | 7-11% | 7-11% | Remainder | 5-9% |

| Molybdenum | – | 8-10% | 8-10% | – | – | 2.8-3.3% | – |

| Niobium & Tantalum | – | – | 3.15-4.15% | – | – | 4.75-5.5% | 0.7-1.2% |

| Cobalt | N/A | 10-15% | ≤0.01% | – | ≤0.10 | ≤1% | ≤1% |

| Manganese | ≤1% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.35% | ≤1% |

| Copper | ≤0.5% | ≤0.5% | – | ≤0.5% | ≤0.5% | ≤0.3% | ≤0.5% |

| Aluminum | – | 0.8-1.5 % | ≤0.4% | – | – | 0.2-08% | 0.4-1.0% |

| Titanium | – | ≤0.6% | ≤0.4% | – | – | 0.65-1.15% | 2.25-2.75% |

| Silicon | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.35% | ≤0.5% |

| Carbon | ≤0.15% | 0.05-0.15% | ≤0.1% | ≤0.05% | ≤0.04% | ≤0.08% | ≤0.08% |

| Sulfur | ≤0.015% | ≤0.015% | ≤0.015% | ≤0.015% | ≤0.015% | ≤0.015% | ≤0.01% |

| Phosphorus | – | ≤0.015% | ≤0.015% | – | – | ≤0.015% | – |

| Boron | – | ≤0.006% | – | – | – | ≤0.006% | – |

The strength and corrosion resistance of Inconel mean that it is relied on in the most extreme environments. Inconel was used to create the superstructure of the rocket-powered X-15 experimental plane because it alone had the properties needed to survive hypersonic reentry. Inconel alloys are also used in the manifolds of the Merlin engines that power Space X rockets and it is used in nuclear reactor cores and control rod mechanisms.

The expense of Inconel pound for pound means that it is only used where nothing else will do. In these applications, it is important to choose a precise, quality welding method for Inconel. At best, failure of an Inconel weld might lead to a rocket failure. In a worst case scenario, failure of an Inconel weld could lead to the poisoning of a geographic area due to the release of nuclear or chemical materials. As a result, it’s important to use GTAW welding with the improved reliability of automation.

Why Automated GTAW Is the Best Way to Weld Inconel

Automating GTAW welding enhances the precision of GTAW even further through precisely performed and infinitely repeatable steps. Automated GTAW arc welders execute the motions of a correct and on-specification weld every time without the human issues of fatigue or forgetfulness.

In the case of Inconel® process piping or fuel lines, automation isn’t just the best way to weld Inconel, it is in effect the only way to weld pipes and tubing with the quality required. Welding around the circumference of a pipe or tube in a single pass is impossible for a welder using manual equipment. Instead, the circumference must be divided into quarters and welded one quarter at a time. The need to start and stop in order to change position during manual welding creates more frequent opportunities for contamination of the weld, along with increasing the potential for structural issues to arise in the formation of the weld. Moreover, the stops and starts required to manually complete a weld around an Inconel pipe offer more opportunities for the weld to crack during cooling.

Automated orbital GTAW welding can complete a full circumference weld of tubing in a single pass. It can also complete a full circumference weld for each pass on large bore pipe welds. As a result, orbital welding offers fewer opportunities for errors to arise and produces higher quality and more reliable welds. Orbital GTAW is also able to significantly improve welding productivity and reduce welding costs. In most circumstances, GTAW welding is simply the best way to weld Inconel. For Inconel pipes and tubing, orbital GTAW arc welding isn’t just the best method, it is the only process able to meet the quality standards required for applications using Inconel.

Arc Machines, Inc. is a long-time leader in orbital GTAW welding, with experience providing the orbital welders used to weld Inconel® in the pioneering days of aerospace. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.