Titanium has a curious nature. It is thought of as futuristic and expensive, and yet titanium is the ninth most abundant element in the Earth’s crust and the seventh most abundant metal. It’s so common, in fact, that titanium oxides are used in sunscreen and as pigment in white paint. It’s only the pure metallic form of titanium that is rare. The metal easily binds with oxygen, and as a consequence, titanium the metal can only be derived by blasting the ore with electricity. It’s very similar to aluminum in this respect, and, in fact, titanium has had a trajectory similar to that of aluminum.

In a few decades, titanium has gone from being used nearly exclusively in top-secret aerospace projects to being used in custom car parts. With its incredibly high strength-to-weight ratio and excellent corrosion resistance, titanium will be used even more extensively in the future. It is already frequently used for high-specification projects and is often welded using gas tungsten arc welding (GTAW). A critical part of meeting the demanding specifications of such a project is choosing the best tungsten for titanium welding.

Welding Titanium and Titanium Alloys

Welding titanium poses a challenge because the metal is a novel one to most industries, and many welders will not have experience welding titanium. If welders merely draw on the experience they’ve built working with other metals, they run the risk of making incorrect assumptions about what is involved in welding titanium. Any welder who has moved from welding steel to welding aluminum and forgotten to check their machine settings should understand the risk very well. Two main characteristics make welding titanium different from welding more familiar austenitic metals like stainless steel and non-ferrous metals like aluminum.

- Reactivity to the atmosphere. Titanium is very reactive to the atmosphere when it is heated, to the point that the entirety of the heat-affected zone, not just the molten metal, needs to be shielded by inert gas. This is because nitrogen, as well as atmospheric oxygen and hydrogen, can bond with titanium, contaminating not only the weld but also the surrounding metal in the workpiece. For this reason, it is necessary to weld titanium with pure argon shielding gas, an expanded gas lens, and backing gas.

- Heat Requirements for Welding. The second noticeably different factor is that welding titanium requires more heat than most other metals. However, the heat requirement is only very slightly higher than that required for welding stainless steel. While it is something the welder should be aware of, it is not a serious obstacle in titanium welding.

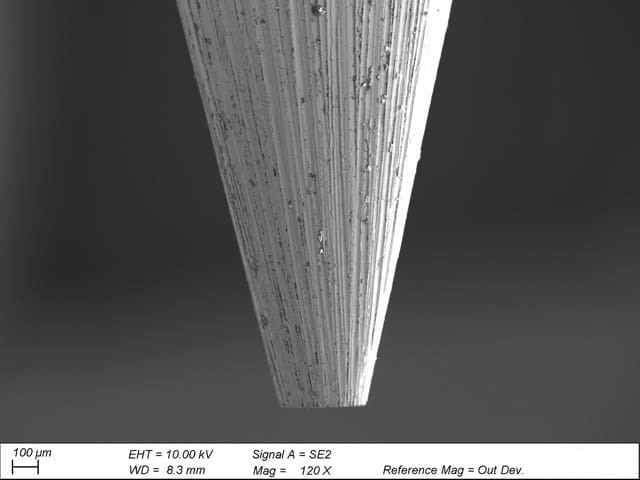

These two factors play a role in the tungsten electrode type and tungsten grind angle a welder chooses for working on titanium. It should also be noted that titanium should be welded with a flat tipped tungsten electrode in which the point is flattened. This helps reduce the potential for tungsten inclusions. Titanium is a metal preferred for high dynamic stress and corrosive applications, and tungsten inclusions in welds are problematic in these applications.

The Best Tungsten for Titanium Welding

Choosing the best tungsten for titanium welding means taking into account the need to maintain a consistently high level of heat on the weld while simultaneously keeping the heat-affected zone as narrow as possible. The high heat needed to weld titanium is the first and most pressing consideration in choosing the right tungsten electrode for welding titanium. It is important to use a tungsten electrode that can withstand the high heat needed to weld titanium without melting or spitting tungsten into the molten weld, which causes weld defects. This means choosing tungsten alloyed with another element that enables it to better withstand higher temperatures. Titanium is usually welded with direct current (DC) and not alternating current (AC), so this limits the range of usable tungsten electrodes to DC-compatible ones. There are three common types of tungsten electrodes suitable for welding titanium, as seen in the chart below.

| Color | Oxide | Tungsten Percentage | Oxide Percentage | Current Type | Advantages |

| Red | Thorium | 97.3 | 1.7-2.2 | AC/DC | Reduced rate of consumption, strong arc starts, reduced tungsten deposition. |

| Gold | Lanthanum | 97.8 | 1.3-1.7 | AC/DC | Excellent arc starting and arc stability at both low and high temperatures. |

| Gray | Unspecified | Unspecified | Unspecified | AC | Gray tungsten alloys are nonstandard tungsten made for specific purposes including welding titanium. |

In addition to these types of electrodes, certain purpose-made tungsten electrodes exist that alloy their tungsten with less standard materials, such as a mixture of rare earths. These electrodes do not fall under the usual color codes and fill very specific roles. They may be the best type of tungsten electrode for certain highly specialized titanium welding projects.

When welding titanium, a good general rule is that the higher the percentage of oxides in the tungsten, the better. A higher oxide percentage helps to keep heat on the weld while simultaneously preventing tungsten spitting and inclusions. The other critical factor in choosing the best tungsten for titanium welding is the tungsten grind angle. A sharp taper on the tungsten will maximize penetration while simultaneously keeping the width of the heat-affected zone to a minimum. This helps to prevent embrittlement of the titanium surface during welding and ensures that shielding gas protects the area, preventing nitrogen from bonding with the metal.

Titanium is a metal with incredible potential. However, it also poses its own unique challenges, particularly when it comes to welding. When working with titanium and looking for the best tungsten for titanium welding, it is wise to seek out welders and weld engineers that have expertise with the metal and with developing weld parameters for these projects.

Arc Machines, Inc. has developed some of the best orbital welding machines and the best tungsten for titanium welding with those machines. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting with our experts.