Corrosion is an omnipresent issue when working with metals. For example, corrosion is an ongoing problem in petroleum extraction, refining, and shipping. The carbon dioxide and hydrogen sulfide in crude oil reacts with steel alloys to form iron precipitates, degrading the structural integrity of the steel. Hydrogen can also infiltrate the grain boundaries of steel and weaken the bond in steel crystalline lattices, making the steel brittle. Offshore petroleum extraction adds seawater to the mix of corrosives, while the pressure of the ocean depths tends to exacerbate corrosion.

In order to resist the action of the corrosive compounds found in crude oil, petroleum companies often line their steel process piping and tanks with corrosion-resistant alloys like Inconel®. The Inconel cladding process has changed over time as new methods of bonding dissimilar metals are developed and refined. These developments have made the Inconel cladding process more flexible—allowing more types of pipes and fittings to be lined—and more robust, allowing

Inconel-clad fixtures to last longer.

The Development of Inconel Weld Overlay Cladding

The earliest Inconel® cladding process was hot isostatic pressing. It involved machining and fabricating an internal lining for the piece to be clad and creating a vacuum-tight space between the body of the piece and the liner. This space was then filled with a powdered form of Inconel or another corrosion-resistant alloy, and the whole assembly was placed into an autoclave where it was heated to high temperatures at high pressures. The powder then melted and formed an Inconel lining inside the piece. This process is a form of sintering metallurgy that is still used to create high-quality Inconel and other metallic components today.

However, the isostatic pressing method of cladding has several drawbacks:

- Size: The size of the pipe and fixtures to be clad are limited by the size of the available autoclave, and the size of the autoclave can limit the number of pieces produced per shift or day.

- Machining: The process depends on keeping powdered Inconel in place with an interior form. Creating this form requires additional fabrication, and machining forms for pieces with complex geometries can be difficult.

- Complexity: Hot isostatic pressing is a multi-step process that involves not only the fabrication and machining of the workpiece and interior lining, but the assembly of the two into a vacuum-tight form with a layer of Inconel between them. A substantial effort is required to ensure that each step is performed correctly.

- Time: The process effectively doubles the amount of fabrication work required for each piece to be clad and adds considerable process work for each step. This increases the time it takes to get from raw materials to a finished product.

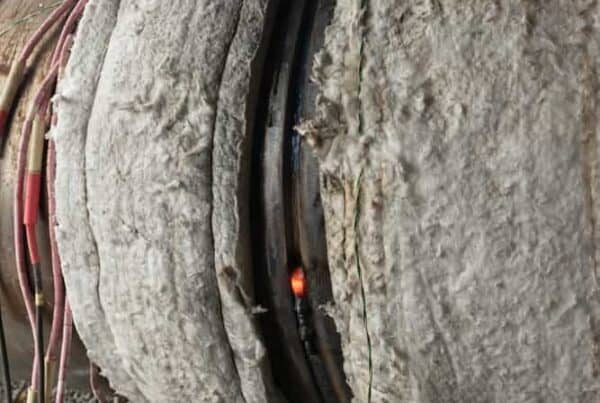

Because of these drawbacks, hot isostatic pressing has mostly been replaced by arc welding cladding processes that deposit a layer of molten Inconel as the welding electrode is moved around the surface. Inconel weld cladding processes have the advantage of requiring less setup and more easily accommodating workpieces with difficult geometries. Several different types of arc welding are used in cladding Inconel, and each has its own tradeoffs.

The Modern Inconel Cladding Process

There are two main concerns related to the Inconel® weld cladding process. The first is the mixing of the Inconel and steel underneath. Creating a strong metallurgical bond requires deep penetration and fusion of the deposited Inconel with the underlying steel. However, good fusion and penetration dilutes the Inconel with iron from the substrate, undermining the purpose of the Inconel cladding process.

Several types of welding are used to clad workpieces with Inconel, and generally each offers a tradeoff between deposition rate and the level of dilution of the Inconel with iron.

Dilution is related to the second concern, which is the speed at which Inconel cladding can be deposited. The faster the deposition speed, the faster the cladding process can be completed. However, fast deposition of Inconel requires high heat, which creates more iron dilution and reduces the Inconel’s corrosion resistance. Several types of welding are used to clad workpieces with Inconel, and generally each offers a tradeoff between deposition rate and the level of dilution of the Inconel with iron from the underlying steel. Their relative advantages and disadvantages can be seen in the chart below listing welding processes used in the Inconel cladding process:

| Process | Deposition Rate | Heat Input | Dilution | Quality | Cost |

| Gas Tungsten Arc Welding (GTAW) | Low | Controllable | Low | High | High, but justifiable |

| GTAW-A(Hot Wire GTAW) | Medium | Controllable | Low | High | High, but justifiable |

| Gas Metal Arc Welding (GMAW) | High | High | Mid to High | Acceptable, though well-known for lack of fusion | Moderate, but rework needs may negate cost savings |

| Submerged Arc Welding | High | Controllable | Mid to high | High, and excellent in the flat position | High, but justifiable. |

| Plasma Transfer | Superior | High | Mid to high | High, and excellent in the flat position | Very high cost investment for limited use cases |

| Laser Welding | High | Controllable | Low | High quality in the flat position | Very high cost investment for limited use cases |

Of the six welding processes listed above, the GTAW Inconel cladding process offers perhaps the best combination of low dilution, high quality, flexibility, and cost-effectiveness. It is also uniquely able to produce high-quality welds in any position. GTAW orbital welding can be used to clad pipe or tubing by having a tungsten electrode lay down cladding while orbiting the interior diameter of a pipe or tube. In contrast, Inconel cladding processes that have excellent quality in the flat position require the pipe or tube to be moved around the electrode and this limits their usable applications. GTAW’s only serious drawback as an Inconel cladding process is its relatively low deposition rate. This can be mitigated by heating the Inconel wire before it reaches the arc (hot wire GTAW), which effectively doubles the deposition rate.

Technically, manual GTAW, GMAW, and shielded metal arc welding (SMAW) can all be used as Inconel cladding processes. However, Inconel is a challenging metal to weld with and the interior of a pipe is a difficult and uncomfortable work environment. The high chromium content of Inconel also makes it a hazardous metal to work with and one that demands careful adherence to OSHA welding safety requirements. For these reasons, orbital hot wire GTAW welding is not only the best way to weld Inconel, but also the most widely applicable Inconel cladding process for most use cases.

Arc Machines, Inc. has decades of experience in manufacturing orbital welding machines and developing weld schedules for the aerospace, nuclear, petrochemical, and other industries. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.