Welding seeks to ensure the structural integrity of fused components to allow their maximum service life. To achieve this goal, manufacturers must choose the correct welding process, heat input, and other similar weld parameters. An important yet often overlooked area for quality welding is filler metals. Because filler metals should fulfill the chemical composition and strength requirements of the welding process, filler material choice is a crucial step in the welding process.

In automated welding processes like orbital welding, correct filler metal selection allows manufacturers to meet welding standards for critical applications. The importance of matching orbital welding filler material and its advantages are discussed in this article.

Matching Filler Metal with Base Metal

Filler material is the main component that fuses two workpieces during welding. As it cools and solidifies, the filler material bonds the two metal pieces into a single unit. The quality of welded components is determined by their mechanical properties and the strength exhibited during their service life. As such, filler metal selection should be based on the loading condition required by the application. Similarly, the choice of metal should also be based on the joint type and the chemical composition of the base material. When dissimilar or lower-grade filler metals are used, the results can produce:

- Reduced tensile and yield strength.

- Structural failure induced by fatigue.

- Cracking and corrosion in the weld area.

- Microstructural deterioration.

Such outcomes can increase downtime, require costly reworks, and reduce productivity in industrial applications. To avoid these problems, consider the following factors for filler metal selection:

1. Base Metal Composition and Strength

Ensuring the chemical compatibility of the filler metal with base metal is very important. Additionally, strength and other mechanical property compatibilities are also important. For instance, aluminum welding generally uses 4043 or 5356 alloy as the filler due to their similarity in chemical attributes. Similarly, Inconel uses alloy 625 as the filler metal. In the case of stainless steel, its different grades make a selection of filler metal difficult. The main goal is to reduce the amount of ferrite in the final weld. Filler metal with closely aligned attributes, such as 308L filler metal for 304 austenitic stainless steel, offers a suitable option.

In welding metals with different strengths, the filler metal should match that of the lower strength base metal. During welding, dilution from the higher strength metal is usually enough to retain weld strength.

The key is to ensure that a similar grade filler metal is used so that the weld quality is not compromised.

2. Welding Specification

Different weld applications need to adhere to industry-specific weld specifications and manufacturing standards. For instance, when welding pressure vessels, all filler materials should conform to the ASME Boiler and Pressure Vessel Code. This helps ensure that the exposure of filler metal to extreme temperature and load environment will not adversely affect the performance of the welded component.

3. Welding Equipment

Welding equipment affects the type and performance of the filler metal. For instance, filler wire with a large diameter requires a power supply system to provide more current. If this combination is not met, the result can be poor weld pool control and splatter that can lead to sub-par welds. Weld operators should ensure that their welding equipment can provide the proper heat or current parameters required by the filler metal.

4. Shielding Gas

Shielding gas plays a critical role in improving weld quality by ensuring proper transfer from the arc and reducing the chances of defects in the weld through contamination. Carbon dioxide, argon, and helium are some examples of commonly used shielding gases that help protect against atmospheric gases like oxygen. The mixture of argon and carbon dioxide is popular among welders when working with carbon steel in processes like GMAW. Argon facilitates tensile strength improvements while carbon dioxide helps build resistance against cracking. By matching shielding gas with filler metal, operators can enhance weld quality.

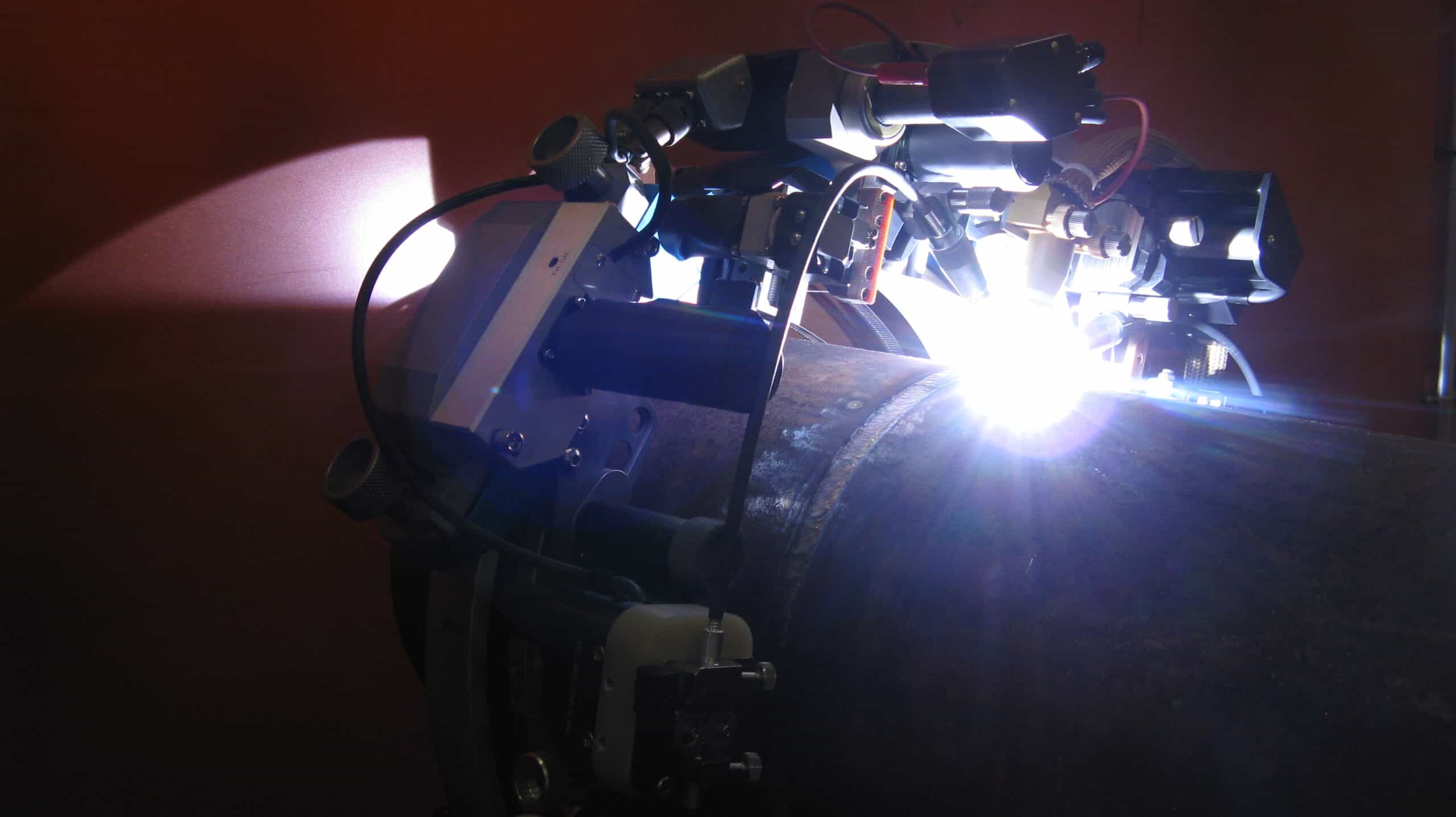

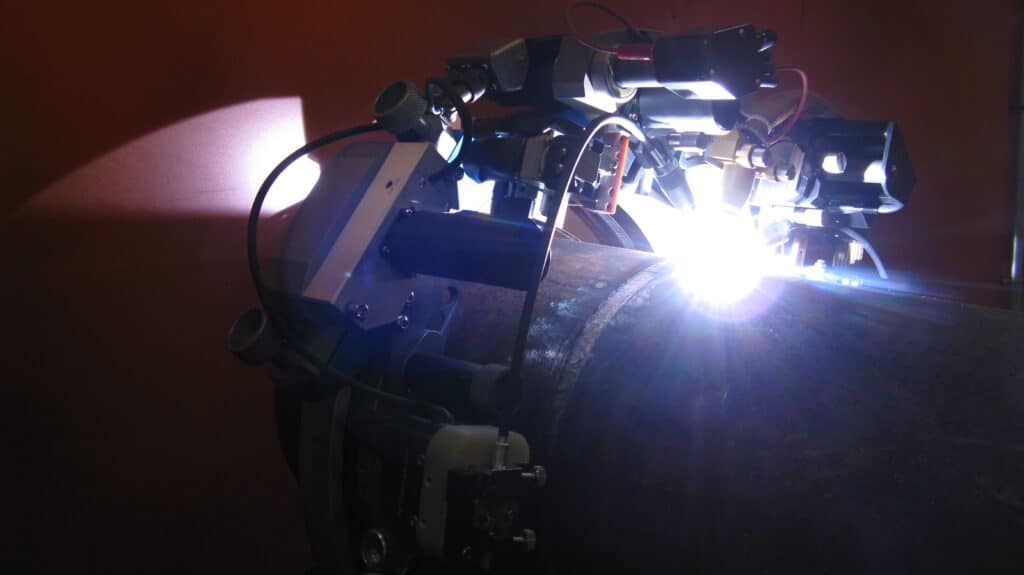

Role of Filler Material in Orbital Welding

Orbital welding improves weld results through its mechanized process. And by ensuring the orbital welding filler material is compatible with the base metal, the final weld quality can be further enhanced, enabling weld results to meet or exceed the specification.

Orbital welding allows for easy optimization and weld parameter control. Leveraging these features to integrate filler metal enables manufacturers to eliminate welding flaws. By properly matching the orbital welding filler material, manufacturers can achieve fast, cost-efficient, and high-quality welds in a single run.

Arc Machines, Inc. provides industry-leading advanced orbital welding machines and weld heads that enable excellent filler material deposition for your critical projects. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Contact us to arrange a meeting. Arc Machines welcomes the opportunity to discuss your specific needs.