Modern engineering and infrastructure projects may rely on pipelines and piping systems to transport fluids, with applications occurring across industries ranging from food and beverage to semiconductor, chemical processing, and oil and gas. Unfortunately, the long history of pipelines includes a parallel history of annual pipeline incidents. In 2021 alone, over six hundred incidents were reported to the Pipeline and Hazardous Materials Safety Administration (PHMSA).

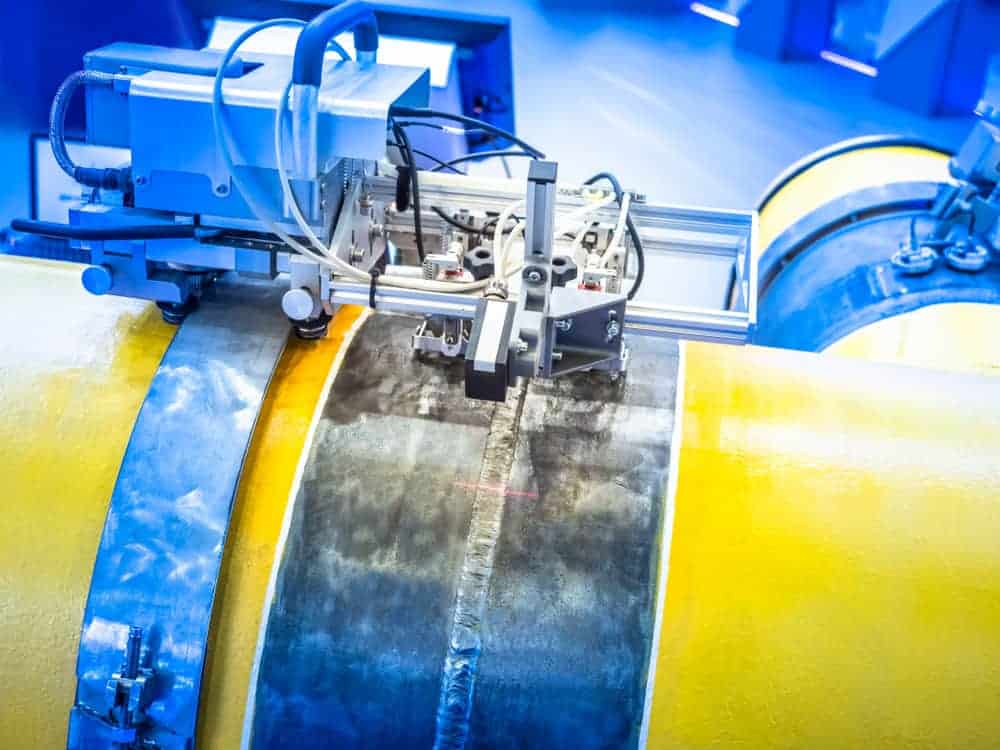

While many welding techniques have emerged to reduce weld defects, issues persist due to welder fatigue and inadequate weld precision. As a result, the move to automated welding machines and pipe welding robots can help produce high-quality, corrosion-resistant pipes that are free of defects and possess high mechanical strength.

Automation and Robotics in Pipe Welding

Traditionally, pipeline welders utilized manual processes such as SMAW (Shielded Metal Arc Welding). Based on material, thickness, strength requirements, and desired finishing, skilled and experienced welders can control weld parameters during the process and lay out the weld beads either remotely or on the factory floor. However, there are limitations:

- Health risks for operators are high when welding manually due to possible exposure to splatters or hazardous fumes (such as hexavalent chromium) when welding metals like stainless steel.

- Repeatable work can lead to human fatigue and may cause judgment errors and potential weld defects.

- Welds are completed at a much slower rate.

- High chances of material waste due to poor welding.

A pipe welding robot presents an ideal alternative to address the issues described above. Welding robots can be fully or semi-automated. In either case, they offer increased precision and productivity. Let’s examine their advantages and disadvantages.

Pipe Welding Robot: What Does it Offer?

Pipe welding robots are automated systems designed to reproduce repetitive welding tasks with the same accuracy and precision in each run. While they provide improved quality and productivity, they can also be expensive and inflexible.

Advantages of Using a Pipe Welding Robot

| Weld positions | Pipe welding robots can easily perform awkward vertical, inclined, and overhead welding tasks, as well as OD and ID cladding, which may be inconvenient to perform manually. |

| Speed and Productivity | Since pipe welding robots are automated, welding can be performed faster and increase productivity without incurring downtime. |

| Accuracy and Precision | Pipe welding can be challenging, with different requirements for each weld application. When performed manually, highly skilled welders are required. Alternatively, a pipe welding robot can be programmed to follow precise weld parameters suitable for the pipe material and thickness. The robot movement can be simulated pre-run, and parameters can be optimized during the run to improve the accuracy and precision of the output. |

| Repeatable | The automated robot follows programmed parameters to produce consistent results. |

| Cost | The accuracy offered by a pipe welding robot helps manufacturers reduce the amount and cost of scrapped materials. Similarly, the also decreases. |

Disadvantages of a Pipe Welding Robot

| Flexibility | While the robots can perform fixed and repeatable pipe welds in difficult positions, they are not flexible enough to perform a wide set of tasks simultaneously. An elaborate change in configuration may be required and could increase downtime. |

| Judgment | Robots perform their assigned tasks; however, if an error occurs during pipe welding, the robots cannot access the scenario and adapt their welding approach accordingly. |

| Initial cost | While a pipe welding robot may be cost-effective in the long run, the initial installation cost can be high. |

What Pipe Welding Robots Need To Produce Quality Output?

While pipe welding robots offer significant advantages, especially for big bore and long-distance pipe welding projects, a pipe welding machine cannot simply weld any type of steel. The quality of output relies on many factors, including:

- Material quality

- Chemical compatibility with the process fluid

- Pipe ends and surface preparation

- Weld parameter programming

- Weld technique selection

Once these factors are carefully considered, a pipe welding robot can be deployed to perform safe welds that meet all industry-specific standards.

Arc Machines, Inc. is a leading welding technology provider, offers decades of expertise in automated welding systems to help achieve your desired pipe welding standards. To explore the suitability of a pipe welding robot for your pipe welding application, contact AMI or sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs.