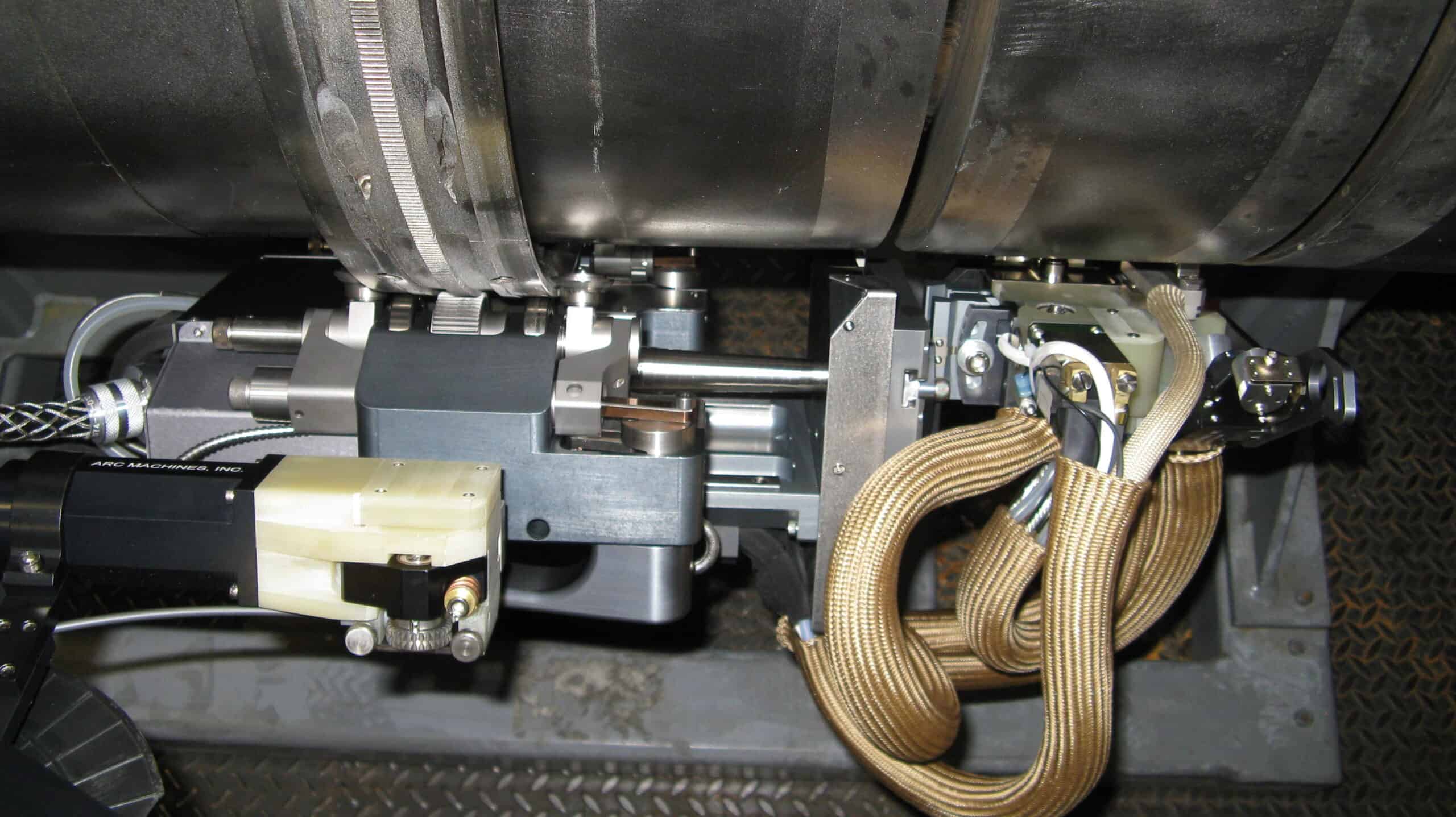

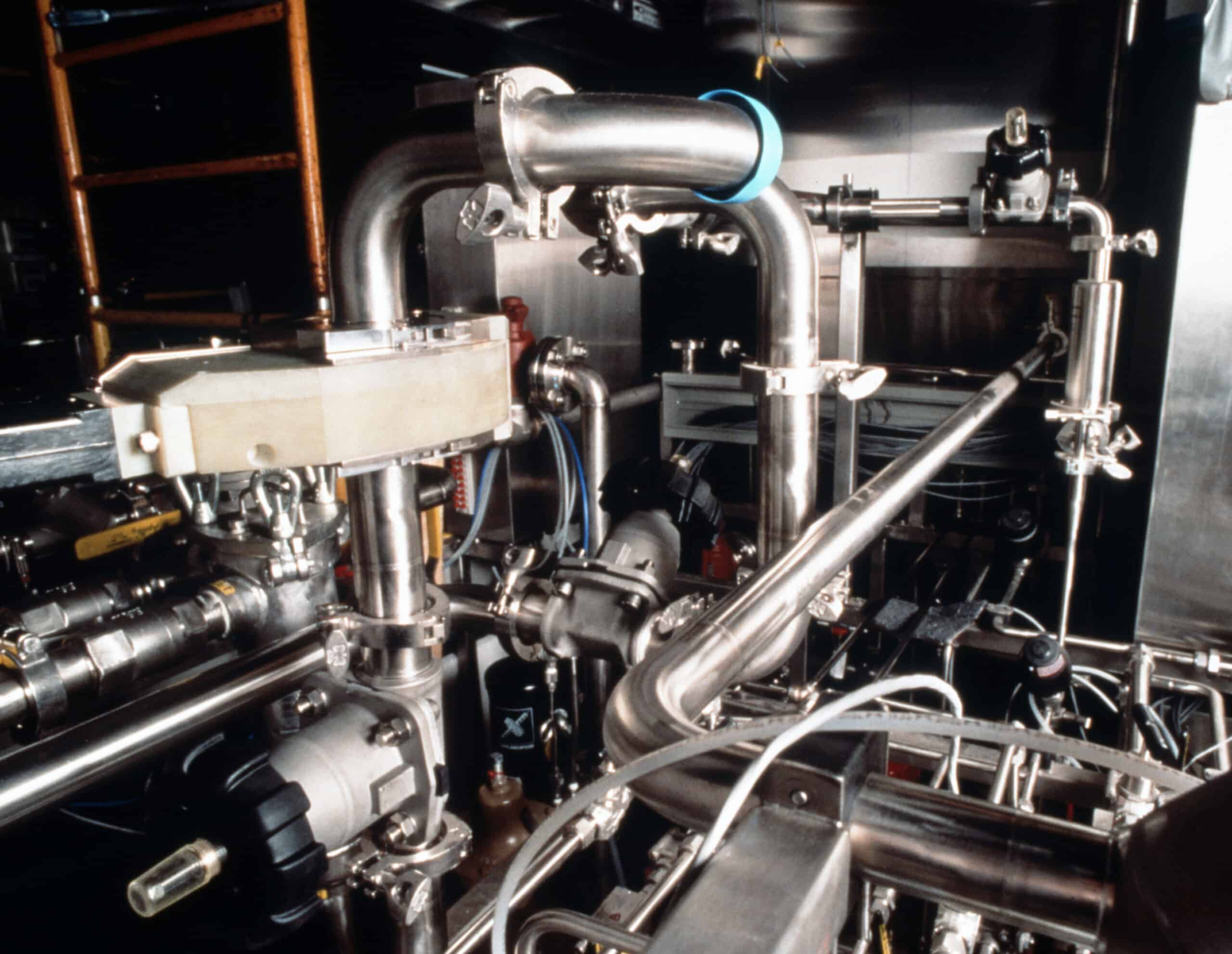

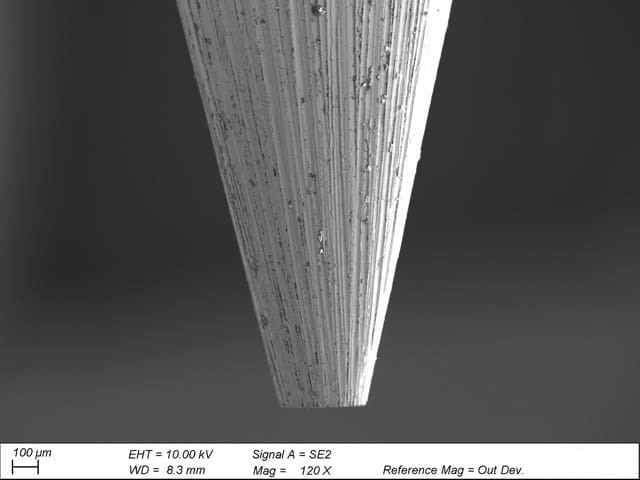

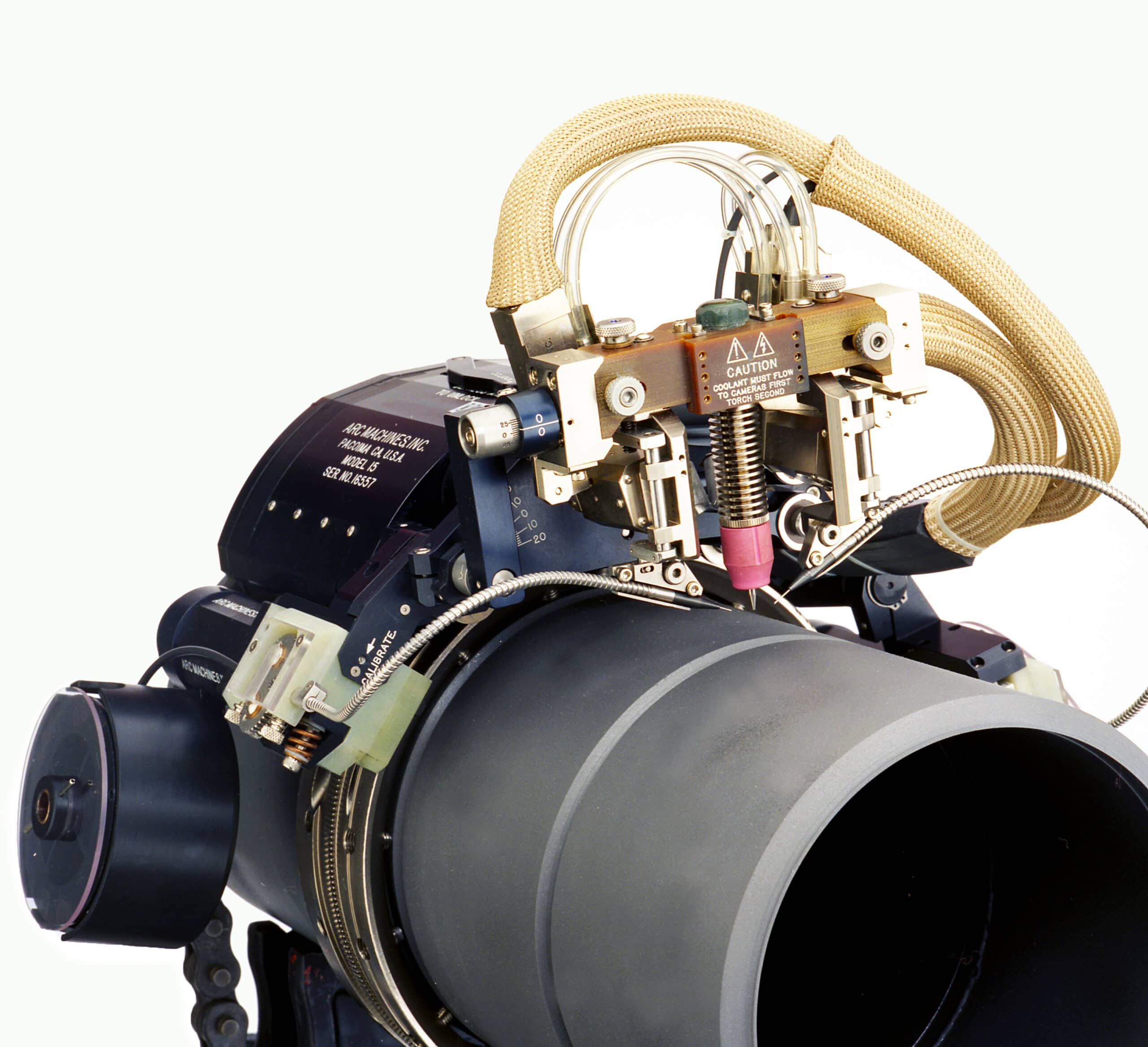

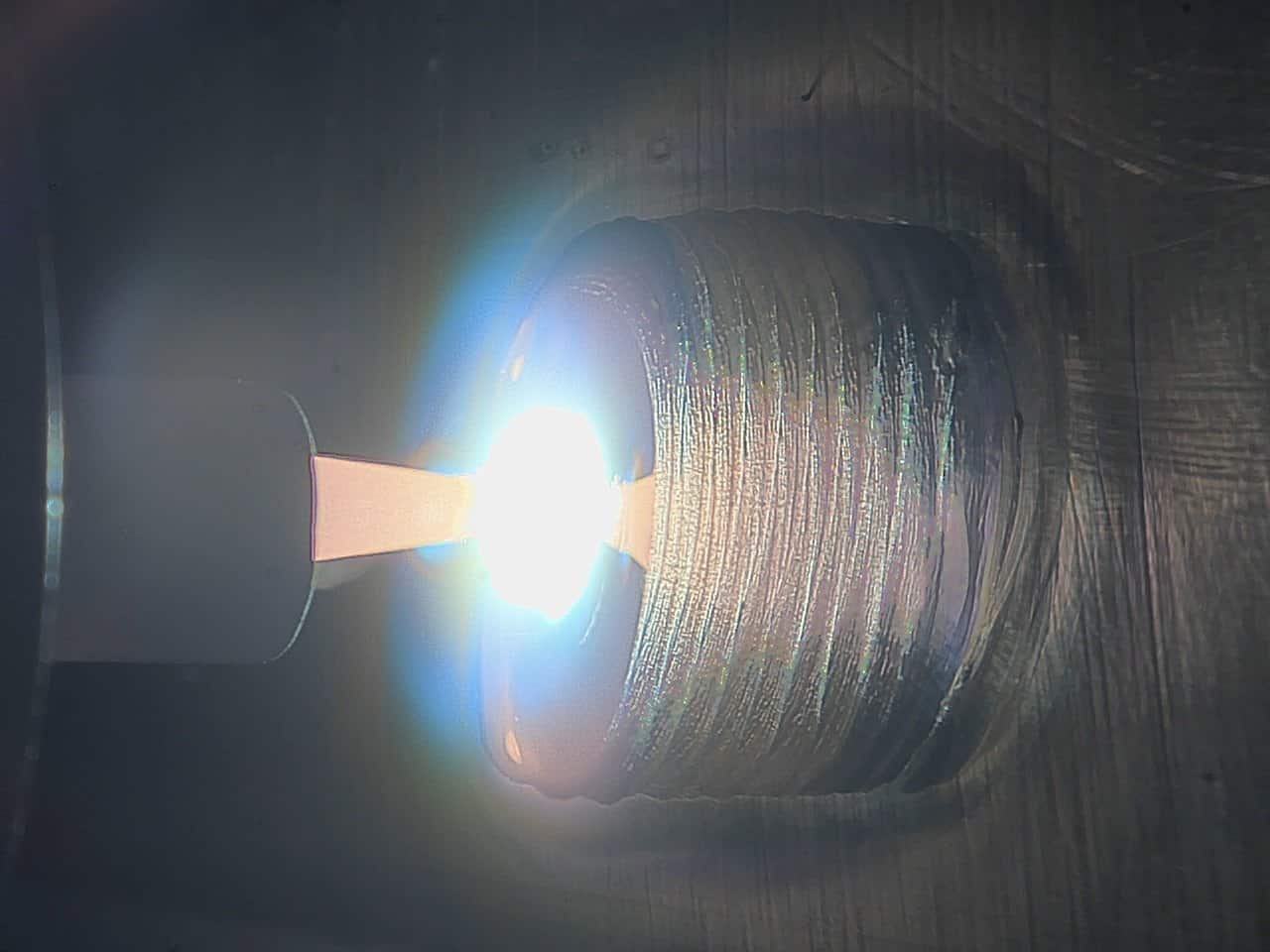

Tungsten is an ultra-dense metal with unique properties that make it ideal for everything from high-strength machine tools to punching holes in armored vehicles. Its most salient property in the field of welding is its ability to endure very high heat without degradation of its tensile strength. This lets it…