For anyone who thinks that the importance of and reliance upon oil and natural gas was diminished or will be soon, you are mistaken. The impact of the hack and partial shutdown of the Colonial Pipeline that supplies much of the east coast in the U.S., as well as the planned construction of the Nord Stream 2 pipeline from Russia to Germany, are prime examples of the continued utilization of oil and gas to meet energy needs around the world. And as long as this is the case, the need for secure infrastructure—pipelines and refinery piping systems—will remain a significant concern.

The assembly of piping systems, both within and external to oil refineries, depends on the quality of petroleum pipe welding implemented. This is due to safety concerns for workers and others near the site, and for the purity of the contents. Hazardous conditions within a refinery may include extreme temperatures, unpleasant odors, and the potential for explosions that may create hydrocarbon vapor clouds and threaten nearby populations. To ensure that a rupture event does not occur requires knowledge of the petroleum pipe welding challenges and the best techniques and equipment to mitigate their occurrence.

Challenges of Petroleum Pipe Welding

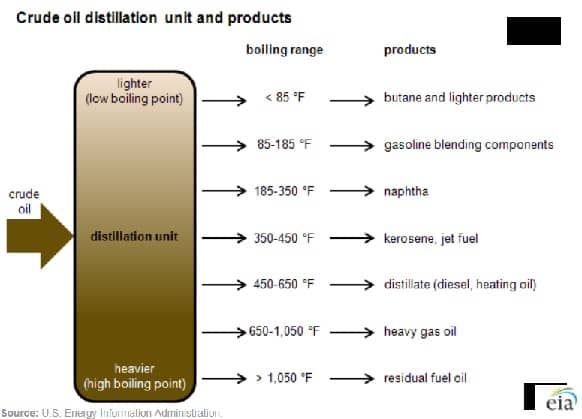

The processes for acquiring the raw materials needed to deliver the petroleum products we rely on for everyday needs can be dangerous. This is especially true when acquiring oil and gas for use as energy, which begins with terrestrial or aquatic drilling, and is followed by thermal processing or refining into fractions—shown in the figure below—and then delivery.

As shown above, the refining of crude oil or distillation into usable petroleum products or fractions involves high temperatures and pressure vessel welding. Additionally, much of the infrastructure for this process is piping, including iron, copper, and plastic (PVC and PE). However, stainless steel may be the most prevalent, and it does come with welding challenges.

Welding Issues for Petroleum Piping Systems

- Toxic fumes

One of the greatest hazards arising from welding stainless steel in any industry is the toxicity of fume clouds generated by the chromium used to manufacture the steel alloy.

- UV radiation

Another significant hazard is exposure to reflected UV radiation. This is also a result of the chromium used that gives stainless steel its shiny appearance.

- Extreme temperatures

As temperature variation and control are essential for the distillation processes in oil refineries, heat exchanger welding is critical to the assembly process for these production operations, which comes with the challenge of ensuring strong, resilient welds to maintain isolation between fluids with different characteristics or properties.

- Hydrogen embrittlement

Another threat to the contents of petroleum piping systems, especially iron and steel, is hydrogen embrittlement, or the introduction of hydrogen ions into the weld or material— typically due to moisture from electroplating or other processes. The result is the breakdown of weld or pipe strength and cracking that can lead to a rupture event for the volatile chemicals used in petroleum processing.

- Iron sulfide scaling

Iron sulfide scaling is a type of contamination that occurs when water and oil are mixed, which is typical for oil well extractions. The degree of scaling can interfere with oil and water separation and require removal.

- Contamination and weld degradation

Undercutting, incomplete penetration, porosity, and other weld defects provide opportunities for microbial contamination that can lead to cracking or more severe breakdowns.

As the list above indicates, manufacturers should consider a wide range of concerns when embarking on a petroleum pipe welding project. Fortunately, most of these concerns can be adequately addressed by choosing the right equipment and implementing the correct process.

How To Overcome Welding Problems for Petroleum Piping

The challenges associated with building assemblies for the petroleum industry span many structures, including oil wells, pumps, refineries, and transportation lines. However, all of these rely on well-built, secure, and safe piping systems. Therefore, it is imperative that the welding of these systems meet the highest quality standards.

Achieving High-Quality Petroleum Pipe Welding

- Process

High-quality assemblies depend on the welding techniques and processes utilized. One of the best techniques for producing quality welds is GTAW or TIG welding. However, to optimize technique consistency and weld strength, it is best to employ an automated orbital process.

- Equipment

By instituting an automated welding system, the advantages of GTAW can be fully realized. Moreover, many safety challenges can be eliminated or significantly reduced. For example, control of the welding process from a distance, which an orbital welding machine with a remote pendant provides, removes the welder from the vicinity of harmful toxic fumes.

- Implementation

When implementing your orbital TIG welding system, utilize the best equipment and materials to reach the high bar required for petroleum pipe welding. Devising and following a good maintenance schedule to ensure that you avoid weld defects that threaten the quality and resiliency of your piping system assemblies is equally important.

Meeting the criteria described above for petroleum pipe welding is best accomplished by partnering with a proven industry expert.

Arc Machines, Inc., since its founding by former NASA engineers in 1976, has been an industry leader in producing high-quality and high-tech welding equipment. This includes orbital welding machines and weld heads that remove many of the challenges of petroleum pipe welding. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.