Blogs about Orbital Welding techniques and best practices.

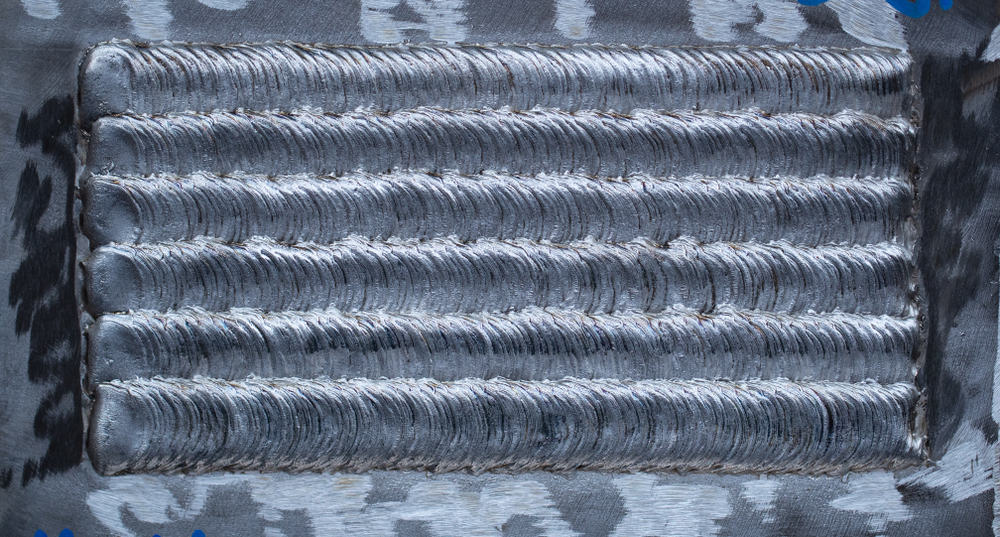

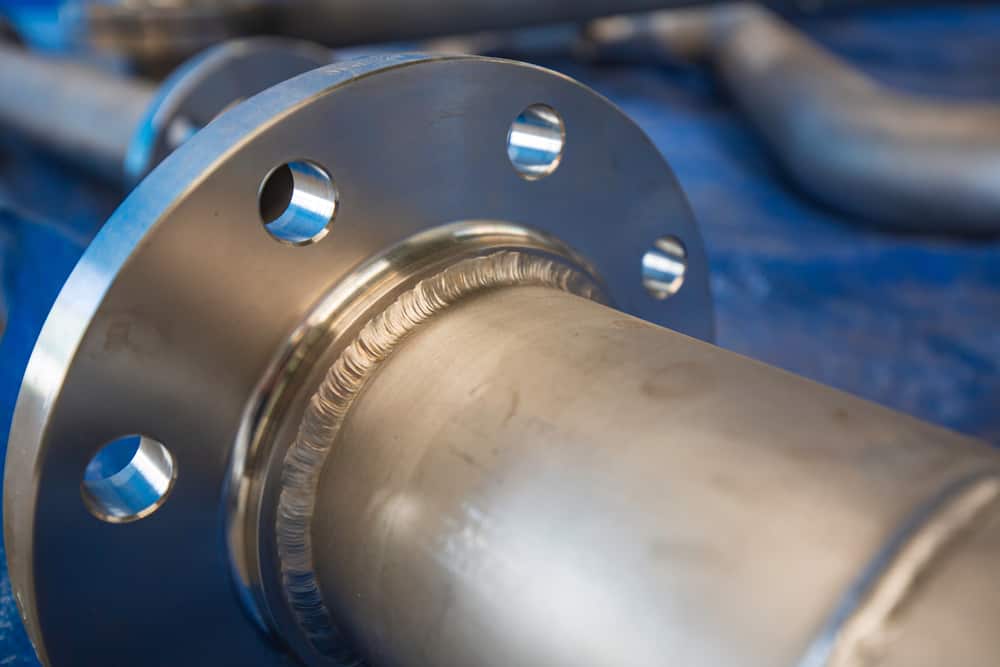

Cladding can enhance a metal’s corrosion-resistant properties. The process involves the deposition of a corrosion-resistant alloy (CRA) layer over a base metal with weaker properties. The most common CRA is stainless steel. Along with its corrosion-resistant properties, stainless steel also offers the benefits of increased strength, temperature resistance, and cost-efficiency. …

Cladding can enhance a metal’s corrosion-resistant properties. The process involves the deposition of a corrosion-resistant alloy (CRA) layer over a base metal with weaker properties. The most common CRA is stainless steel. Along with its corrosion-resistant properties, stainless steel also offers the benefits of increased strength, temperature resistance, and cost-efficiency. …

As a tried-and-tested method, manual welding is still preferred by many pipe welders, even with the increased productivity and reliability available through innovative welding technologies. However, in industries like oil and gas, the extent and complexity of welding pipes can make high-quality welds challenging to produce. Additionally, the risk of…

Vessels are used in critical industrial applications to store or process fluids at high pressure. Standard pressure vessels are designed o contain fluids at pressures greater than 15 psi. High-pressure vessels can withstand 10,000 psi and above. With the inherent risks of high-pressure environments, a pressure vessel should display the…

Materials in the oil and gas industry (and other chemical processing industries) should offer resistance to corrosion, high temperature, and high pressure. Additionally, they should possess excellent strength characteristics and be easy to fabricate. Carbon steel has been the industry standard for piping and tubing, but it can be corrosive…

Pipeline safety has been a perennial concern for industries and technicians. Most pipeline damages result from issues like corrosion, incorrect handling, material, and weld failure. With large diameter pipes—especially as the large diameters pipes are used for critical oil or water transportation over a long distance—these damages are more likely. …

Cladding and overlay are commonly used terms in welding. In manufacturing, the cladding and overlay processes are implemented to enhance the strength of pipe, tubes, or similar components being fused. Because the terms are similar, however, they are often used interchangeably. This article will discuss the difference between the cladding…

In manufacturing, clean rooms are defined by the clarity of air and acceptable concentration of airborne particles. As a result of industry purity specifications established by standards such as ISO clean room standards, clean rooms can provide the ideal operating environment to allow processes like welding to yield high-purity results—especially…

The terms “orbital welding” and “automated welding” are often used interchangeably. While not altogether inaccurate, there are more aspects to orbital welding than process automation. Although automated machines, weld heads, and controllers are a normal part of orbital GTAW welding, manual supervision and adjustments remain essential aspects of orbital welding. …