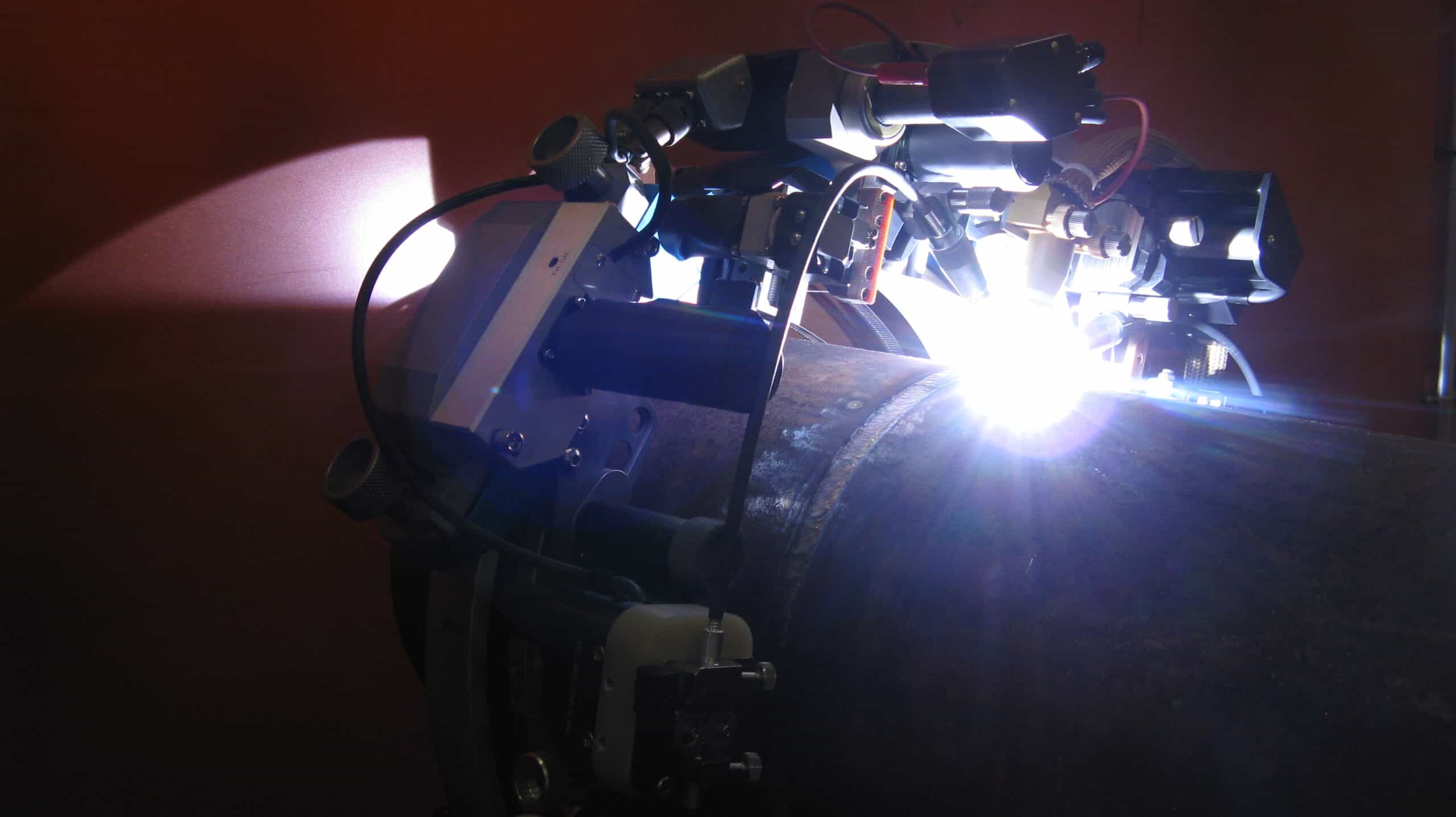

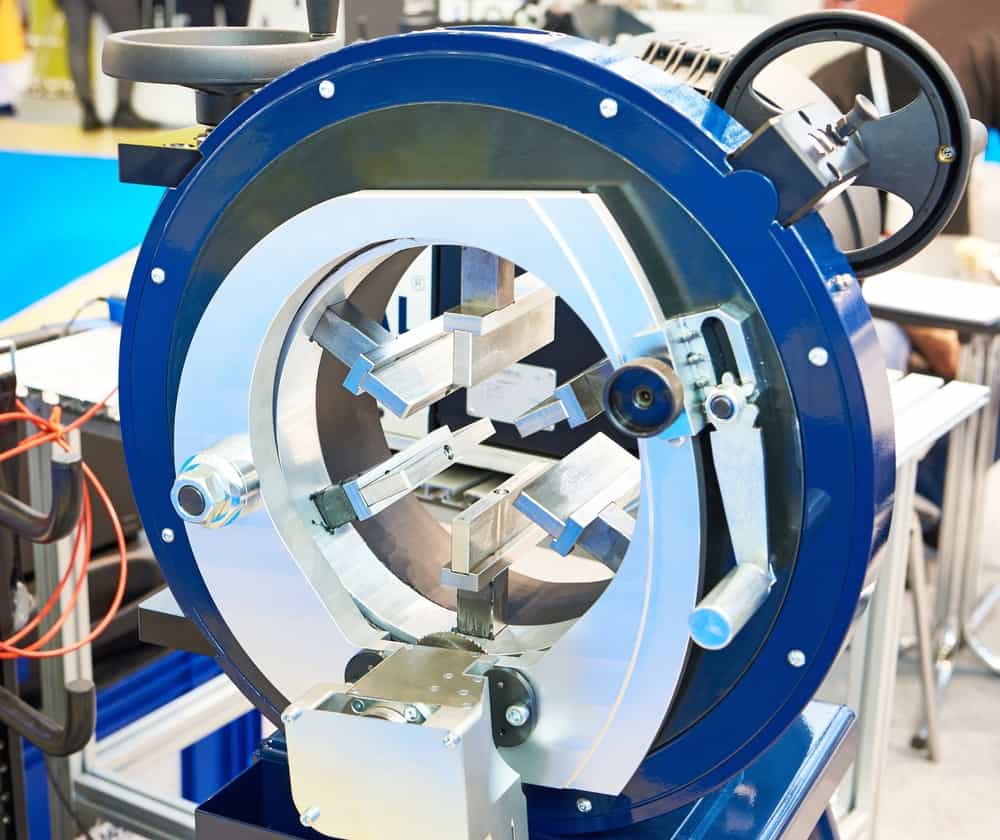

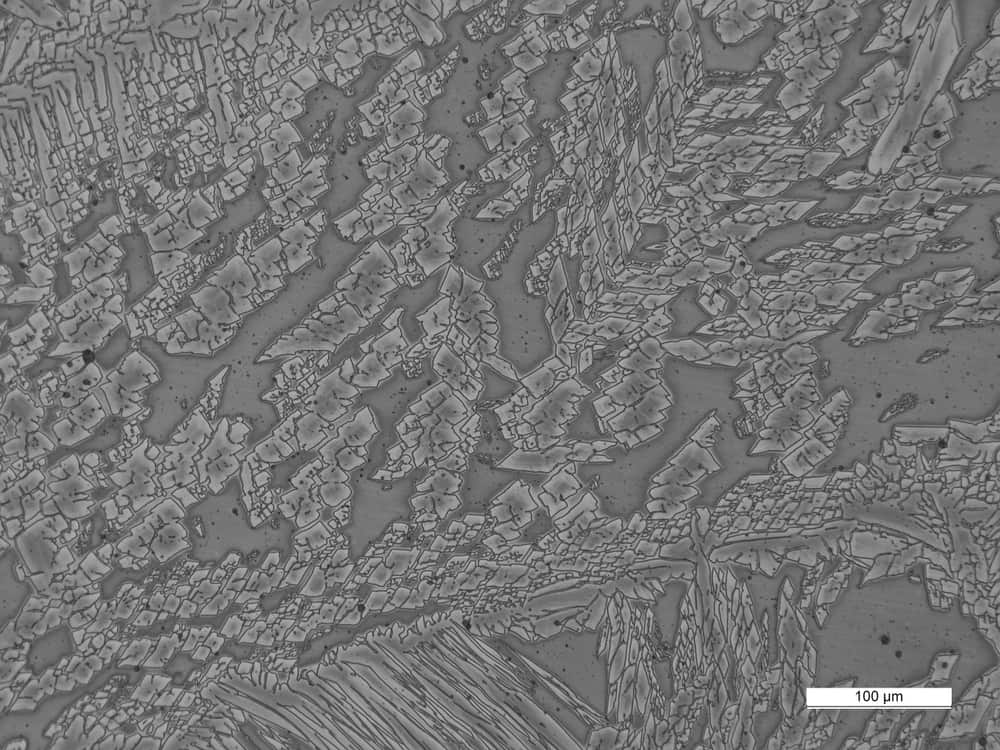

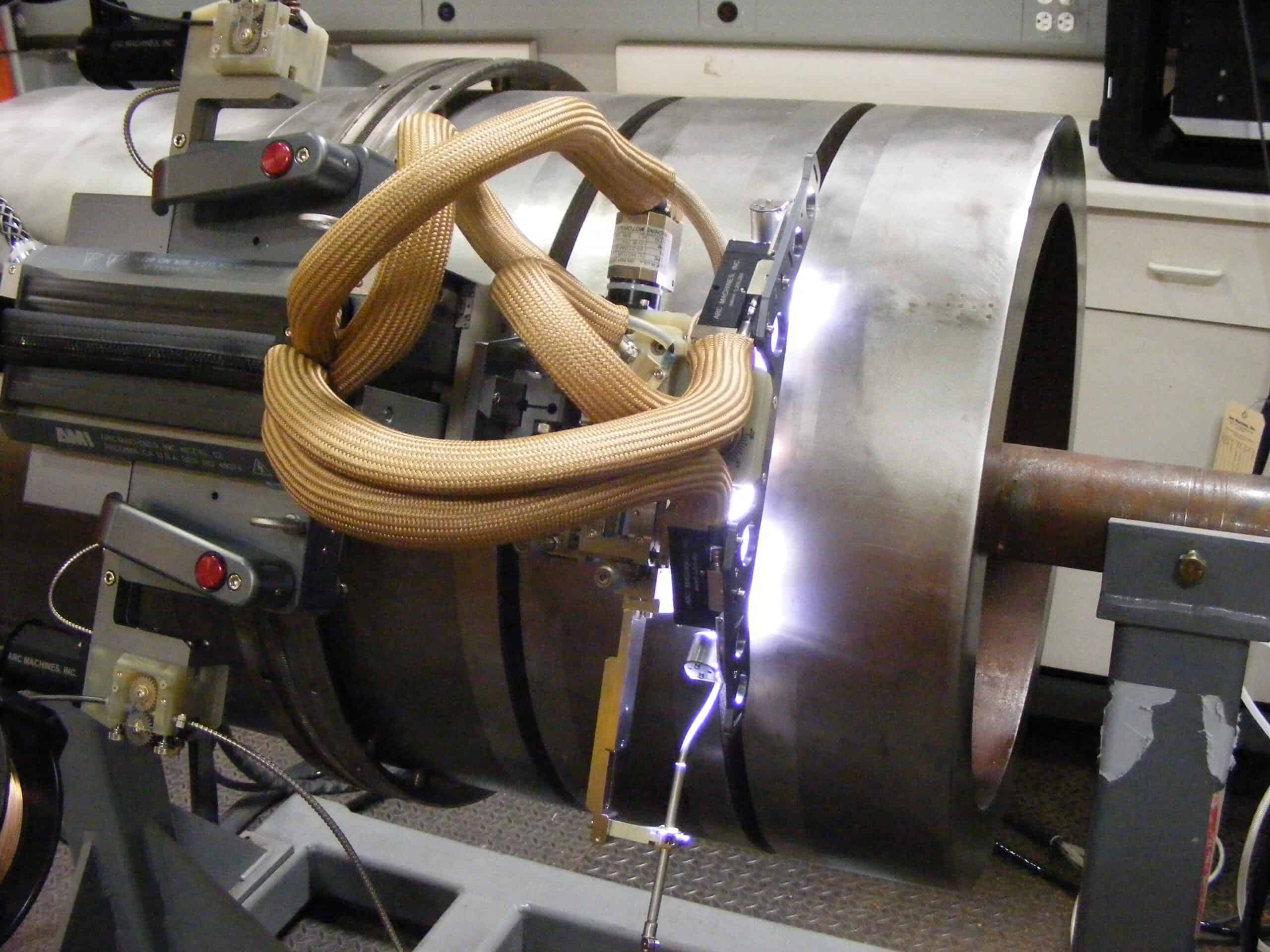

Applying manual welding skills on critical weld projects requires years of technical training and experience. And the process can still result in slow speeds, reduced productivity, and even worker injury. Also, any weld defects—like those that result from welder fatigue—must be addressed. Compared with the effort manual welding requires, orbital…