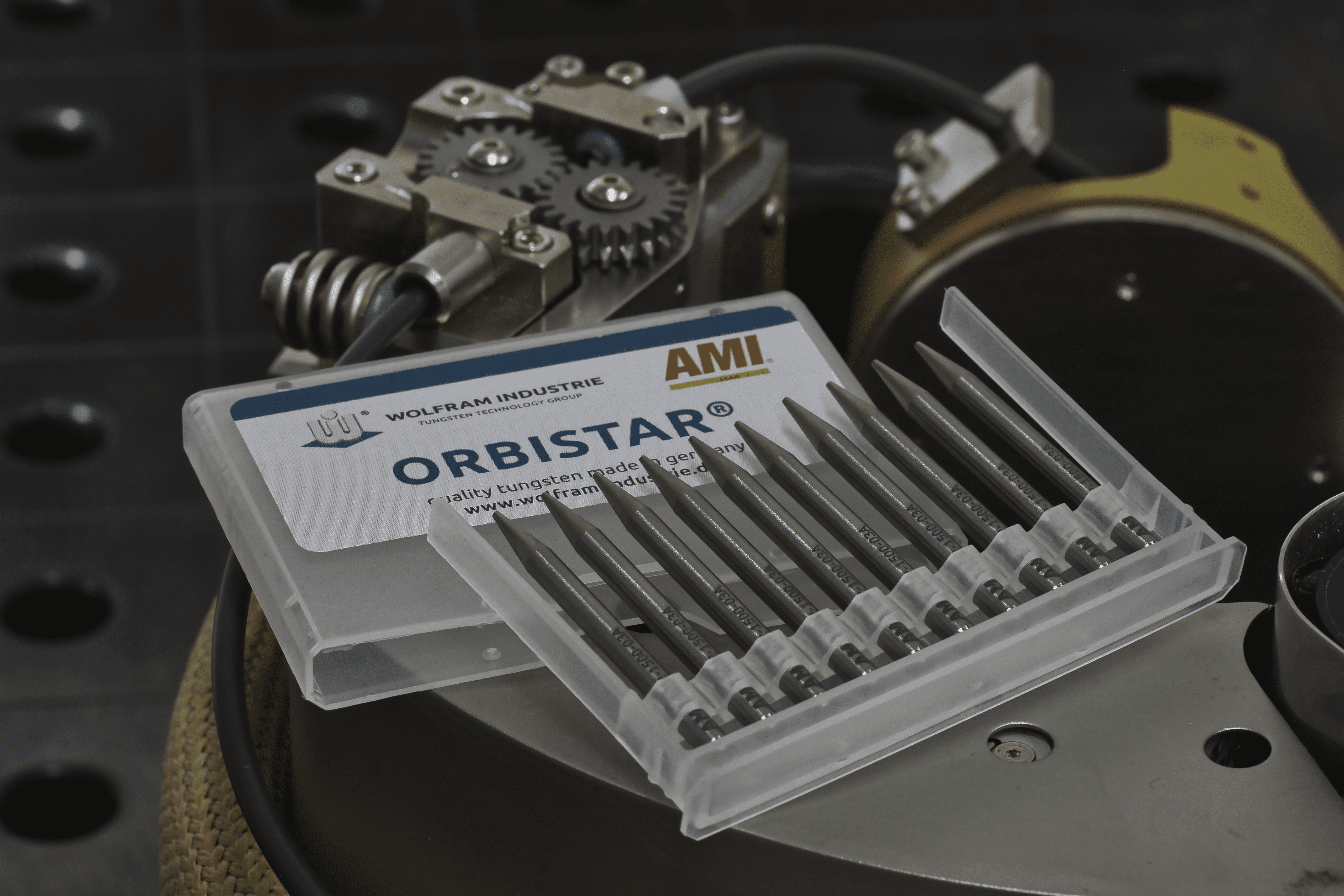

Welding technology investments only become successful when manufacturers take the small details into account. These details can include weld parameters such as feed rate amperage, oscillation, and the material used during the process. Electrode selection, likewise, represents a relatively low-cost detail; however, an improperly selected electrode can result in thousands…