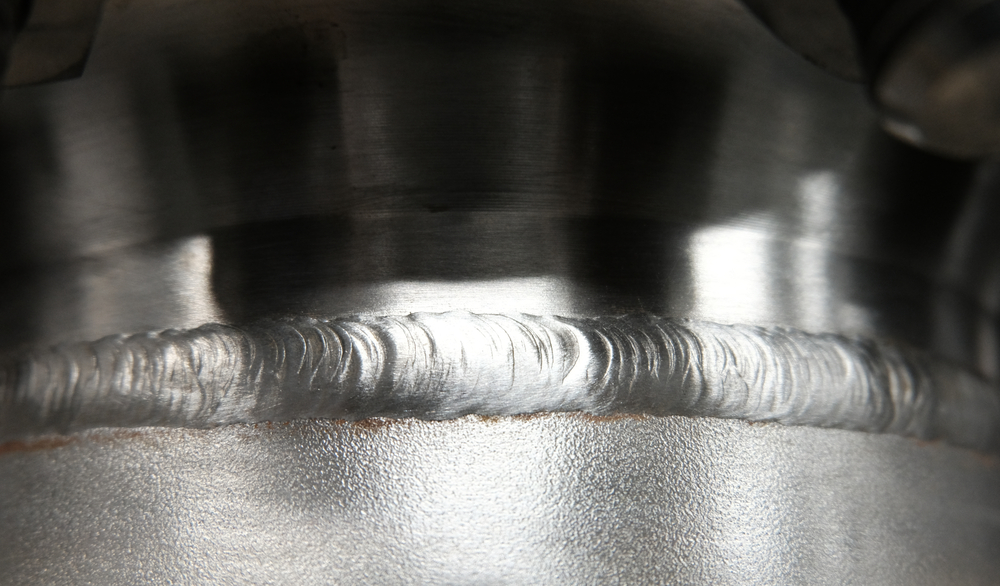

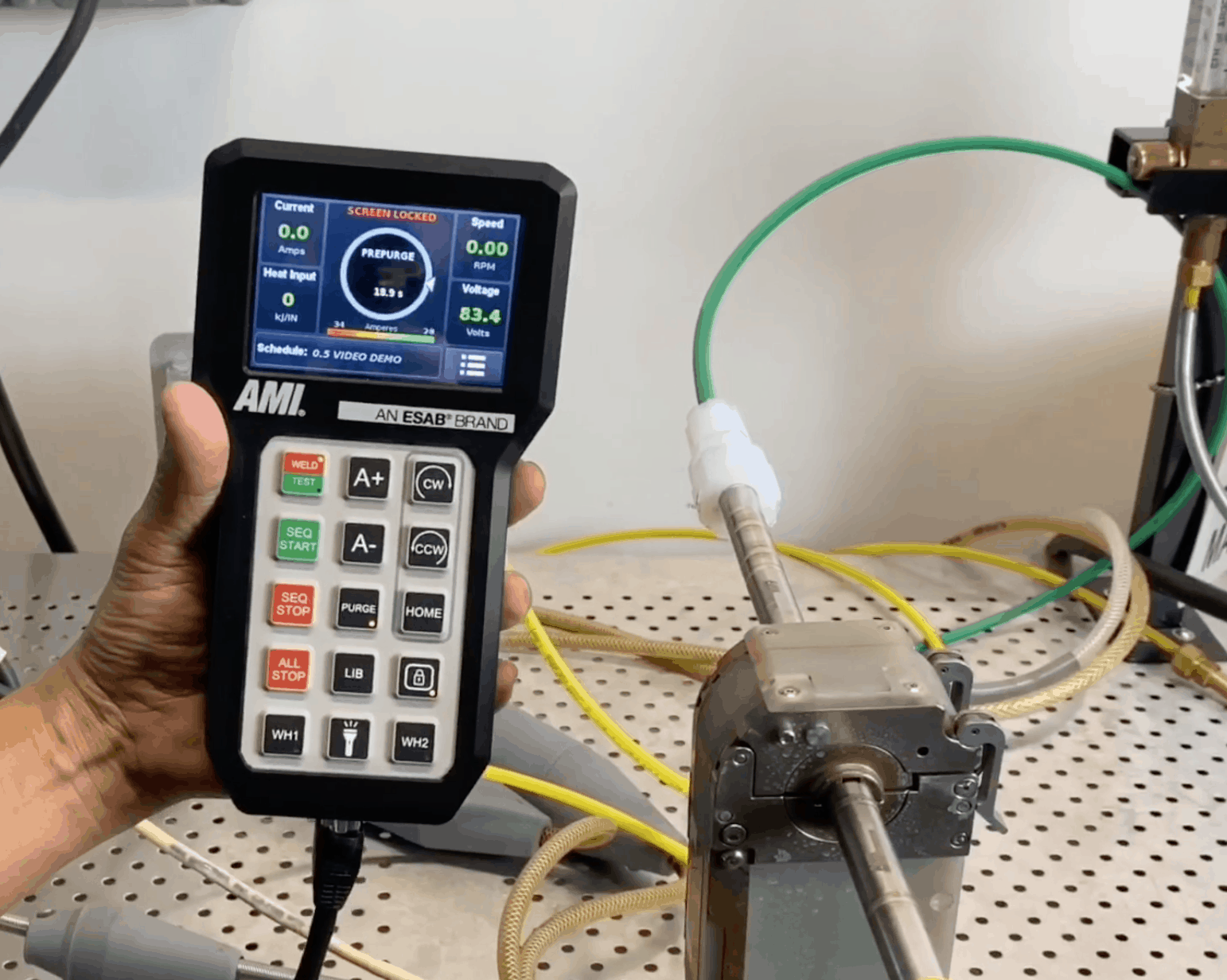

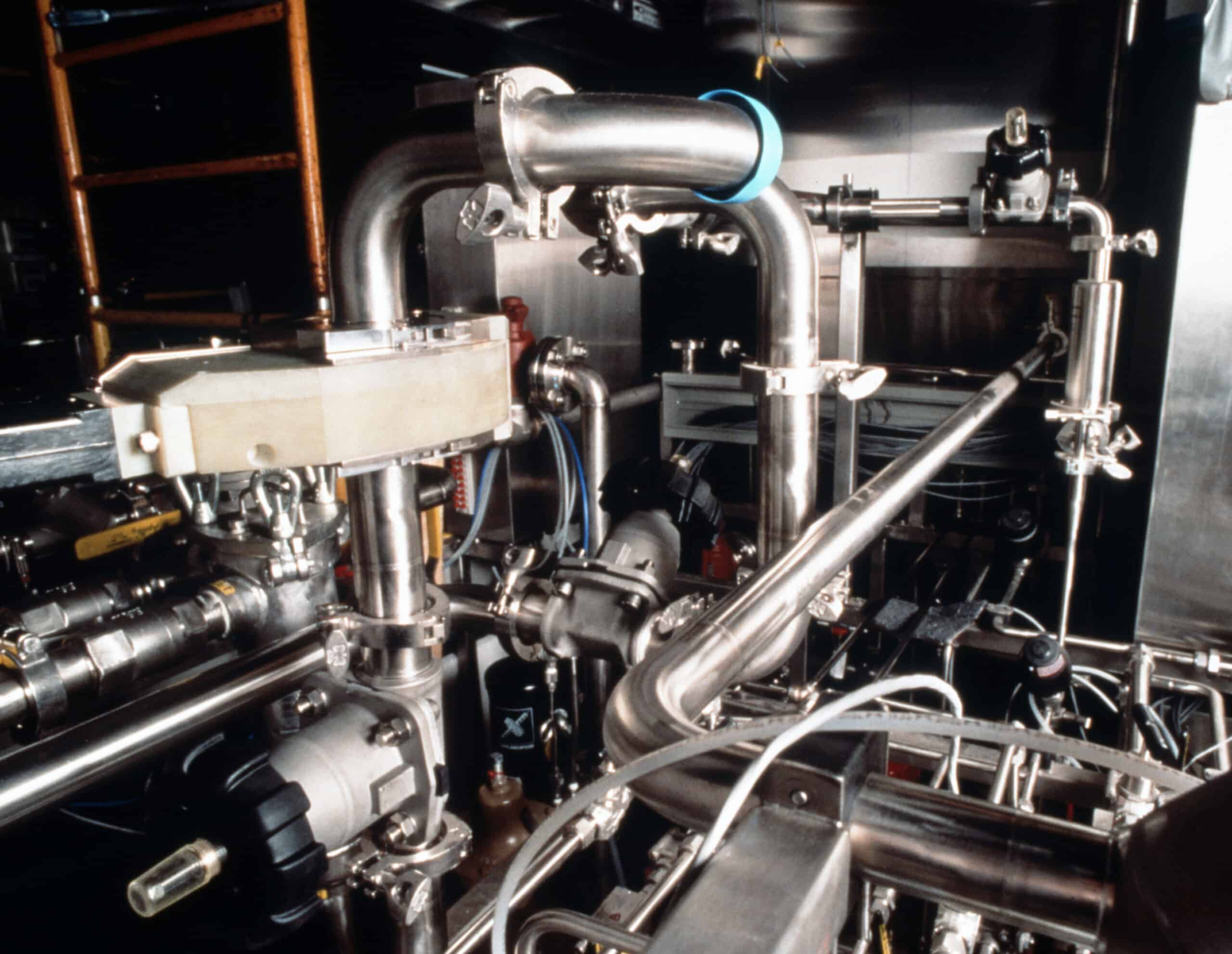

Pressure vessel welding encompasses many applications and industries. At the lower end, any system that operates at 15 psi is considered a pressure vessel. However, systems like boilers and storage containers used in pharmaceutical and food processing, as well as in facilities like power plants, including nuclear generation, are critical…