Tubes used in demanding industrial applications must be strong, durable, and corrosion-resistant to operate reliably in high-temperature and high-pressure conditions. The metal for such applications is chromoly, or chromoly steel, a steel alloy composed of chromium, molybdenum, carbon, and iron. The cumulative properties of these alloying elements make chromoly steel ideal for tubing purposes in shipbuilding, power generation, and aerospace engineering.

However, these properties also make welding chromoly challenging. Improper welding parameters and techniques are likely to alter the properties of the metal, leading to brittleness and loss of strength. As such, it is important to note the best practices required when TIG welding chromoly.

Basics For TIG Welding Chromoly

Chromoly is known for its excellent weldability, thanks to its alloying elements, such as CR and MO, and low carbon content. The different arc welding processes are suitable for welding this metal. However, the welding process requires extreme control of heat input.

There are some things to note, which include:

- Overheating or quick cooling leads to the formation of intermetallic compounds causing the metal to become brittle—leading to cracking and failure.

- Especially in thin sections, high heat input may cause distortion or burn-through, while low heat input may cause a lack of penetration.

- Non-uniform heat input leads to chromoly warping and bending, compromising the integrity and strength of the weld.

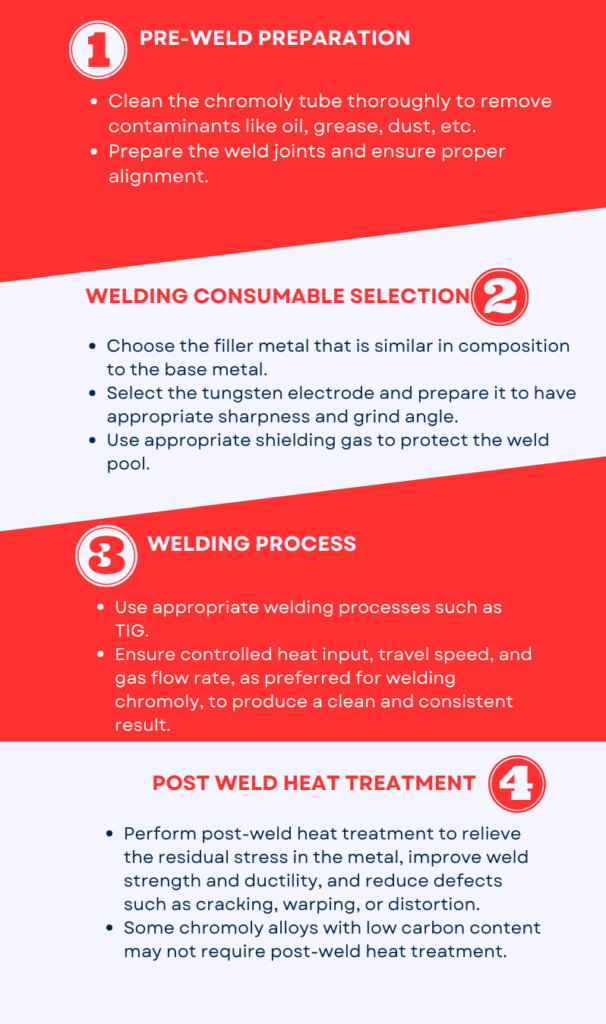

Overcoming these challenges of chromoly welding means the operator should be careful and select the right welding technique, accurate weld parameters, and pre and post-weld treatments, as required. The chart below contains basic guidelines when TIG welding chromoly.

Recommended Parameters

The table below outlines the recommended choice of electrodes, shielding gas, filler metals, and other parameters when TIG welding 4130 chromoly steel tube.

| Electrode Type | 2% Ceriated tungsten or Thoriated tungsten |

| Tungsten Diameter | 1/16 inch to ⅛ inch (depending on the thickness of the material) |

| Filler Metal | ER70S-2 (has high strength and ductility) ER80S-D2 (has a higher level of Cr and Mo- provides better corrosion resistance and strength than ER70S-2) |

| Shielding Gas | Argon or Helium |

| Polarity | DCEN (DCEP may be used for thicker material) |

| Preheat / Interpass Temperature | 400-500°F (AISI 4130) 550-650°F (AISI 4140) |

| Post weld Heat Treatment | 1500-1600°F |

Why Is TIG the Best Welding Option?

Chromoly is a metal with a high strength-to-weight ratio—even when thin-walled or lightweight, it’s stronger when compared to other metals. Welders generally prefer TIG when welding chromoly tubes for its ability to maintain precise control over the weld parameters. This means a high-quality weld can be produced without compromising on the strength of the metal.

While metal inert gas (MIG) welding or stick welding are other potential options, they don’t provide the same level of precision and control.

Here are a few other reasons that make TIG welding chromoly the process of choice:

- Precise control over the weld parameters allows the welders to make adjustments whenever a deviation is observed.

- With the use of inert shielding gas, chromoly has a low risk of contamination. This produces a clean weld and prevents the metal from becoming brittle or losing its corrosion-resistant properties.

- TIG welding enables low heat input, preventing issues like overheating, burn-though, cracking, or distortion.

- TIG is suitable for welding thick or thin-walled tubes.

Achieve Precision By TIG Welding Chromoly Tubes

Chromoly is a sensitive metal that requires extreme welding precision—especially regarding heat input or cleanliness, to retain its strength and toughness. This is why TIG welding is the ideal welding technique.

Apart from leveraging the benefits of TIG, it is extremely important to ensure the proper alignment of tube sections, select ideal welding equipment, set up the correct parameters, and carefully monitor to achieve high-quality welds when TIG welding chromoly tubes. A carefully planned and controlled weld will produce a result that reduces the risk of failure over time and meets all standards.

Arc Machines, Inc. has been a leading provider of high-quality tube welding equipment for decades. To learn more, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. If you want to discuss the advantage of our welding solutions for TIG welding chromoly tubes, contact us today to arrange a meeting. Arc Machines welcomes the opportunity to discuss your specific needs.