Stress corrosion cracking is an issue of increasing concern. Occurring in high heat service environments or highly corrosive service environments, or a combination of both this is a type of intragranular grain boundary cracking that can seriously shorten the lifespan of even high specification metals like Inconel or other nickel based superalloys. The process is related to remnant stresses introduced into the arc welding heat affected zone during joining.

This heat induced stress is one of the most common causes of stress corrosion cracking. Welding stress corrosion cracking is especially problematic because the stresses are subtle with no obvious way to detect them until corrosion has started. With the resulting cracks undetected until routine non-destructive testing (NDT) notices them. This necessitates replacement of the component. More concerning is that welding stress corrosion cracking can dramatically shorten the lifespan of a component and lead to sudden unexpected failures before the issue is discovered.

What Causes Welding Stress Corrosion Cracking?

At the most basic level stress corrosion cracking happens due to stress in the metal creating vulnerabilities to corrosion that would not otherwise be there.There has been an awareness of the potential for stress corrosion cracking in many industries since the middle of the twentieth century. Nevertheless it still retains a bit of mystery due to it being the result of a mix of mechanical and chemical factors. Some of which are desirable on their own, but lead to disaster in combination. Stress corrosion cracking requires three elements to be present in the service environment to occur:

- Applied or residual stresses in the metal

- A corrosive media, with chlorides and sulfides being common culprits

- Continuous or repeated elevated temperatures.

The key ingredient in stress corrosion cracking is stressed metal. This can be caused by a number of factors. The manufacturing of many metal pipes and tubes is done via extrusion through a die. This extrusion process stresses the metal, causing permanent deformation. This actually enhances the metal’s strength through strain hardening and is often desired in many applications. However, it is a remnant stress and in the presence of elevated temperatures and corrosive products like water and chemicals it can lead to stress corrosion cracking.

This process can also happen during the working of a metal. Bending pipe and tube can also introduce stress into the metal. However, welding stress corrosion cracking is specifically caused by the actions of the arc heating the metal causing it to expand. When welding ceases the metal contracts as it cools down. The expansion and contraction of the metal leads to unpredictable patterns of remnant stress that can cause welding stress corrosion cracking. This can be an issue in production welding for pipe and tube systems and pipe welding quality control in general as many of the products these systems contain are corrosive. Meeting the expected service life of these systems means minimizing welding stress corrosion cracking.

How to Minimize and Prevent Stress Corrosion Cracking

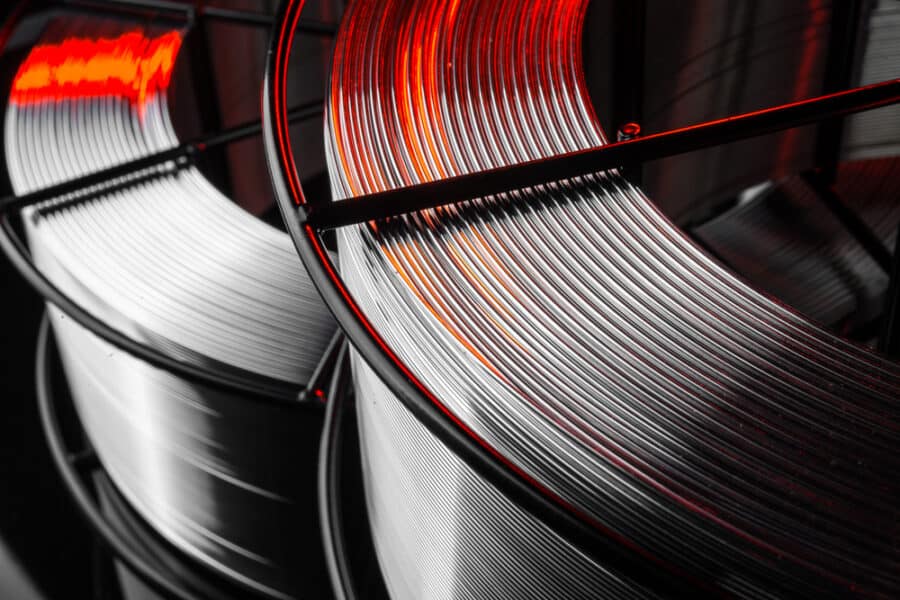

The easiest way to deal with welding stress corrosion cracking is to minimize the heat input into the metal. Welding being a process that involves bringing the metal into a molten in order to join it, this is a tall order that is best accomplished through the use of Gas Tungsten Arc Welding (GTAW). This is a highly controlled welding process which uses a tungsten electrode to keep high heat levels confined to a very narrow area. Significantly reducing the size of the heat affected zone.

GTAW automated pipe welding systems can further limit the heat affected zone of the weld through careful control. The quality of the welds produced through GTAW is also very high which helps to remove the potential for stress cracking in the weld itself. This is, however, an incomplete solution as the area on either side of the weld is still potentially vulnerable to remnant stress as it expands and contracts with heating and cooling.

A more thorough solution to the issue of welding stress corrosion cracking is to carefully control the heating and cooling of the metal. This can be accomplished by heating the metal before it is welded, and carefully controlling the rate at which it cools down. This is the same process that is used to temper metals after production. While it is very effective it is also time consuming, energy intensive, and challenging in most shop or field welding environments.

Post welding heat treatment where the temperatures of the entire welded joint are brought up to an elevated temperature allowing stress to be relieved and then allowed to cool at an approximately even rate across the workpiece is also effective at helping to relieve remnant stress that leads to welding stress corrosion cracking. It is also somewhat easier to perform in the environments where most welding takes place.

Arc Machines builds robust GTAW orbital welding equipment for demanding industries like petrochemical processing, thermal power generation, and nuclear power where preventing welding stress corrosion is vital. Contact us to find out more about our equipment and how it can meet your critical high specification welding needs.