Because of the speed of wire feed welding, welders coming from more demanding manual processes tend to enjoy their first time using a wire feed process like gas metal arc welding (GMAW) or flux core arc welding (FCAW). Pairing a wire feed with automated orbital welding offers a similar experience. In fact, orbital wire feed welding is one of the best ways to weld pipe. Instead of manually adjusting every variable during the welding process, the welder simply has to set up the machine properly and monitor the weld to ensure it is completed correctly.

However, as wonderful as wire feed orbital welding systems are for improving welding productivity, they are not magical devices. They are complex, precision machines with parts that may wear out or cause weld faults due to improper maintenance. Orbital wire feed welding problems do happen, but they are usually fairly simple to remedy and many can be avoided by keeping orbital welding equipment and machinery in good repair.

How Orbital Welding Avoids Wire Feed Lining Problems

Orbital welding machine operators with prior welding experience who encounter a wire feed problem will probably look first to the wire feed liner. The most common wire feed welding problem in GTAW, FCAW, and most other types of wire feed welding is a worn feed liner. The feed liner guides the wire from a spool—usually mounted inside the machine—out to the weld head. It is an easy part to ignore, and, over time, the smooth interior will wear away, creating friction with the wire. As a result, the wire will start slowing down randomly before shooting out with excessive speed or force when the friction is overcome and the wire begins melting back or tapping into the workpiece.

Issues with the wire feed liner are rarer in orbital welding, partly because the distance between the wire spool and the weld head in orbital welding is significantly less than in manual processes. In addition, the wire feed liner isn’t subjected to as much tension, torquing, and general abuse as it is in manual welding, where it is part of the connection between the welding gun and the power supply. However, in orbital welding, wire liners are often required to make a tight bend or two due to the desire to keep a small envelope. These tight bends are a point of wear. Following an orbital welding machine maintenance checklist and ensuring that preventative maintenance and servicing are performed on-schedule will keep this issue from arising.

Common Orbital Wire Feed Welding Problems

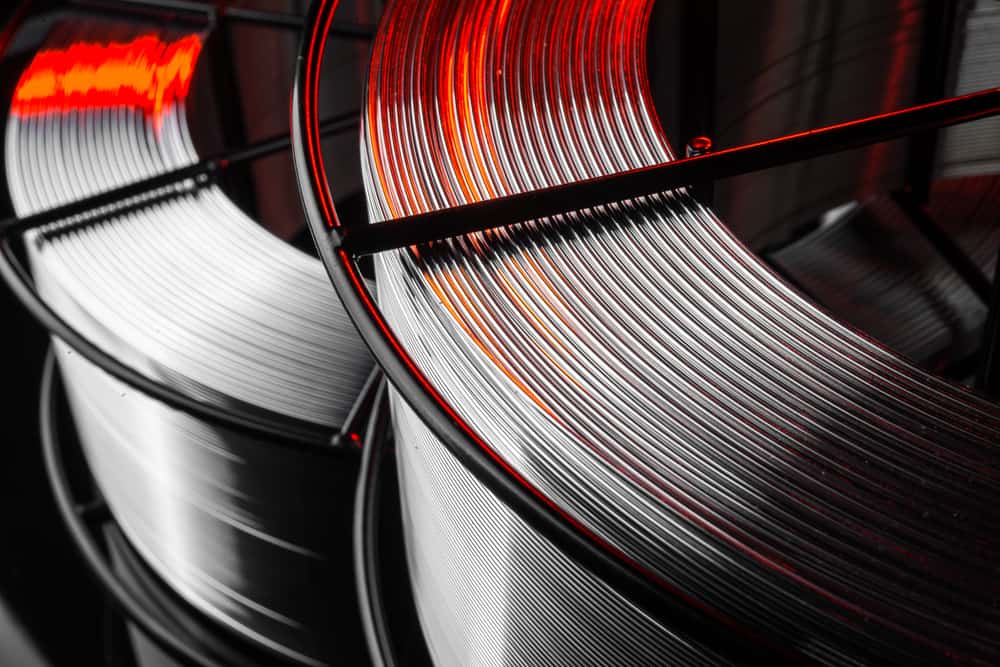

Orbital wire feed welding problems tend to be due to particularly challenging work materials or are unique to the orbital welding process. One of the biggest advantages of orbital welding, for example, is the ability to weld pipes in very cramped workplaces in factories, refineries, and other production sites. In order to weld in small spaces, the wire spools must be wrapped very tightly so they can be mounted to the weld head while still maintaining a low profile.

Since orbital welding is largely automated, hardware issues can cause wire feed welding problems due to mistiming.

If an operator is encountering orbital wire feed welding problems, the most likely issues are:

- Incorrect Wire: Using the correct wire for the job is incredibly important from both a materials standpoint and a process standpoint. A wire diameter that is slightly too big can cause the wire feed to bind up and feed at unpredictable intervals or not feed at all.

- Incorrect Conduit Size: Another common cause of orbital wire feed welding problems is an incorrectly sized conduit for channeling the wire. This can cause issues similar to a worn wire feed liner, although in this case the liner is not worn. Instead, the problem is that the conduit is too small to allow the wire to move freely.

- Faulty Hardware Connections: Since orbital welding is largely automated, hardware issues can cause wire feed welding problems due to mistiming. Hardware problems might be as simple as a loose connection in the weld head or between the weld head and the power supply, which can cause a signal noise that throws off timing.

- Calibration Issues: An orbital welding machine out of calibration can cause timing issues due to sensors reporting inaccurate information, which causes the machine to not respond properly or to feed too little or too much wire into the weld puddle, causing weld quality issues. This problem is best remedied by the manufacturer or a certified service provider.

Another potential cause of orbital wire feed welding problems is the welding filler material itself. Orbital welding can be performed using relatively common materials like carbon and stainless steels, but due to its cleanliness and reliability, it is often the preferred welding process for piping and tubing made of high-specification, expensive alloys like Inconel® and Hastelloy®. These alloys are very strong and the fill wire made of them is extraordinarily stiff.

Orbital welding with wire made of these alloys in tight or inaccessible locations may create a number of orbital wire feed welding problems because of the combination of stiff, inflexible wire and tightly wound, compact spools. The best solution, in this case, is to get ahead of potential problems by contacting a manufacturer of orbital welding machines and developing welding parameters, schedules, and methodologies that take into account the unique challenges of these materials.

Arc Machines, Inc. is a trusted orbital welding solutions designer and manufacturer for high-specification industries, including nuclear, aerospace, and defense. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Contact us to learn more about custom wire feed pipe welding solutions.