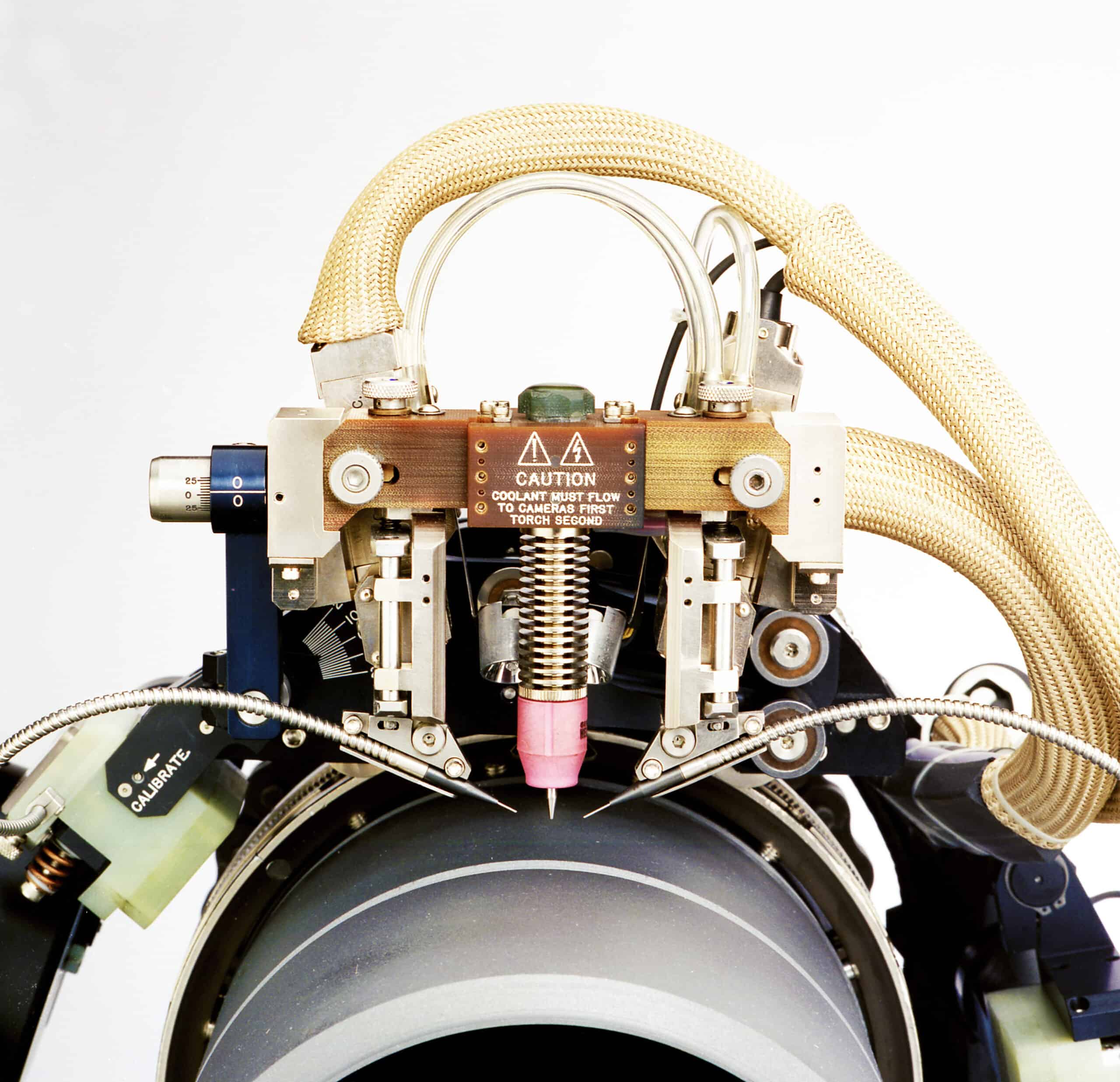

Most welding companies tend to delay arc welding machine calibration until every other effort to fix a problem has failed. In manual welding, failure to perform timely machine calibration often forces businesses to purchase another machine in order to complete work by the deadline. This is the reason that so…