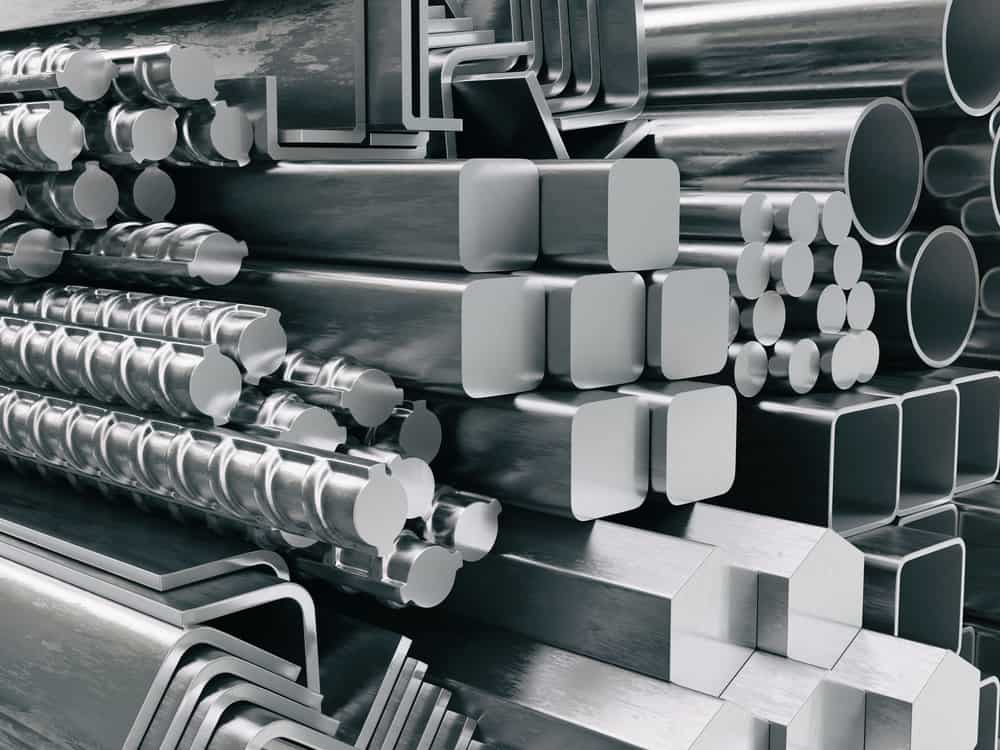

Only a few materials perform well in extreme manufacturing conditions. Inconel is one of those extraordinary materials. Although slightly more expensive, Inconel is a preferred material across wide-ranging industries that include nuclear, aerospace, power generation, and chemical processing plants. With high-quality welds, Inconel pipe can prevent leaks and provide corrosion…