Manual welding diagnostics and repair is straightforward for manual welding machines. It is the sort of thing that is often done entirely on the shop floor even for relatively complex setups like Gas Tungsten Arc Welding (GTAW) machines. The same is not true of sophisticated orbital welding machines. These are far more complex systems that involve custom gearings, small servos, and highly specialized control modules. There are far fewer issues the average operator is capable of diagnosing and fixing themselves.

Many parts of orbital welding diagnostics and Tungsten Inert Gas (TIG) weld head repair require a cross-disciplinary skillset that most welders simply haven’t had the opportunity to cultivate. This is a concern because orbital welding machines are critical infrastructure, and a downed machine can delay timetables for weeks while waiting on repairs—either shipping to the manufacturer or waiting for a representative to arrive.

Orbital and manual machines share some common characteristics that experienced welders can diagnose and repair on their own.

Having said that, orbital and manual machines share some common characteristics that experienced welders can diagnose and repair on their own. With remote support over phones or other devices, there are many other faults in orbital welders that can be readily diagnosed and remedied in the shop.

Troubleshooting Orbital Welder Issues in the Field

The majority of orbital welding machine faults are often basic, visible problems that are capable of being repaired by field operators without guidance. Coolant and gas leakages are obvious issues that fall in this realm. Repair is often as simple as tightening a connection or replacing a hose. This is straightforward, and nearly anyone can do it.

Potentially less obvious, but still easily remedied issues, are power connections. When it comes to timing problems in welding patterns or arc voltage, the most likely culprit isn’t a flaw or damage to the weld head, but a loose connection somewhere between the weld head and the power supply. Checking to ensure that all connections are fastened tightly should be the first step on an orbital welding maintenance checklist when trying to diagnose a problem, along with making it a part of a routine arc welding machine 5-minute daily inspection checklist.

Other similarly easy repairs may not be readily obvious, but a manufacturer’s technical support team should be able to help you troubleshoot. Remote orbital welding diagnostics can help identify these issues and walk onsite personnel through the steps needed for TIG weld head repair or power supply checks, ultimately saving everyone the cost of equipment downtime.

Using Remote Diagnostics for Power Supplies and TIG Weld Head Repair

Orbital welders are sophisticated systems that combine precise mechanics with computer controllers. There are a fair amount of simple steps that can be missed or performed incorrectly, which can ultimately cause error messages or welding issues. A pre-welding calibration error is an example of this kind of difficult to diagnose but easy to fix repair.

Before starting a weld, autogenous orbital welding heads must find a home position against which they compare positioning for all parts of a welding parameter. Don’t confuse this with a more thorough annual calibration to make sure that all parts of an orbital welding system are operating within expected parameters. If a weld head is unable to find the home position it will result in an error message; if it finds an incorrect home position, then it can negatively affect welding performance. The cause of these issues may not be obvious to those that don’t have in-depth familiarity with orbital welding systems. Nevertheless, it is a straightforward fix involving adjustments to a simple switch that the operator can easily be walked through over the phone with the manufacturer.

Remote diagnostic services can identify simple and easy to remedy services without removing orbital welding machines from the site.

There are other simple error messages or easily remedied faults that at first glance might seem like complicated issues requiring manufacturer services. Remote diagnostic services can identify simple and easy to remedy services without removing orbital welding machines from the site or having them out of service for a length of time that adversely affects deadlines.

The Future of Remote Diagnostics and Repair

The modern world’s connectivity offers many diagnostic options for manufacturing equipment like orbital welding through IoT in welding. The weld process data captured through interconnected orbital welding equipment can be used to accurately and quickly diagnose problems with welding equipment remotely. They can be used to anticipate problems before they have a chance to develop with preventative maintenance practices offering considerable time savings.

However, more prosaically, this networking also offers easy and swift access to detailed engineering drawings of orbital welding systems. This allows moderately experienced welders to better analyze and diagnose problems for TIG weld held repair in the field, especially when guided by someone with a great deal of experience. This remote service can be enhanced through the use of other remote technologies like augmented reality, where an experienced technician from the manufacturer can see what the machine operator sees and can guide them through set up, diagnosis, and even repairs if needed.

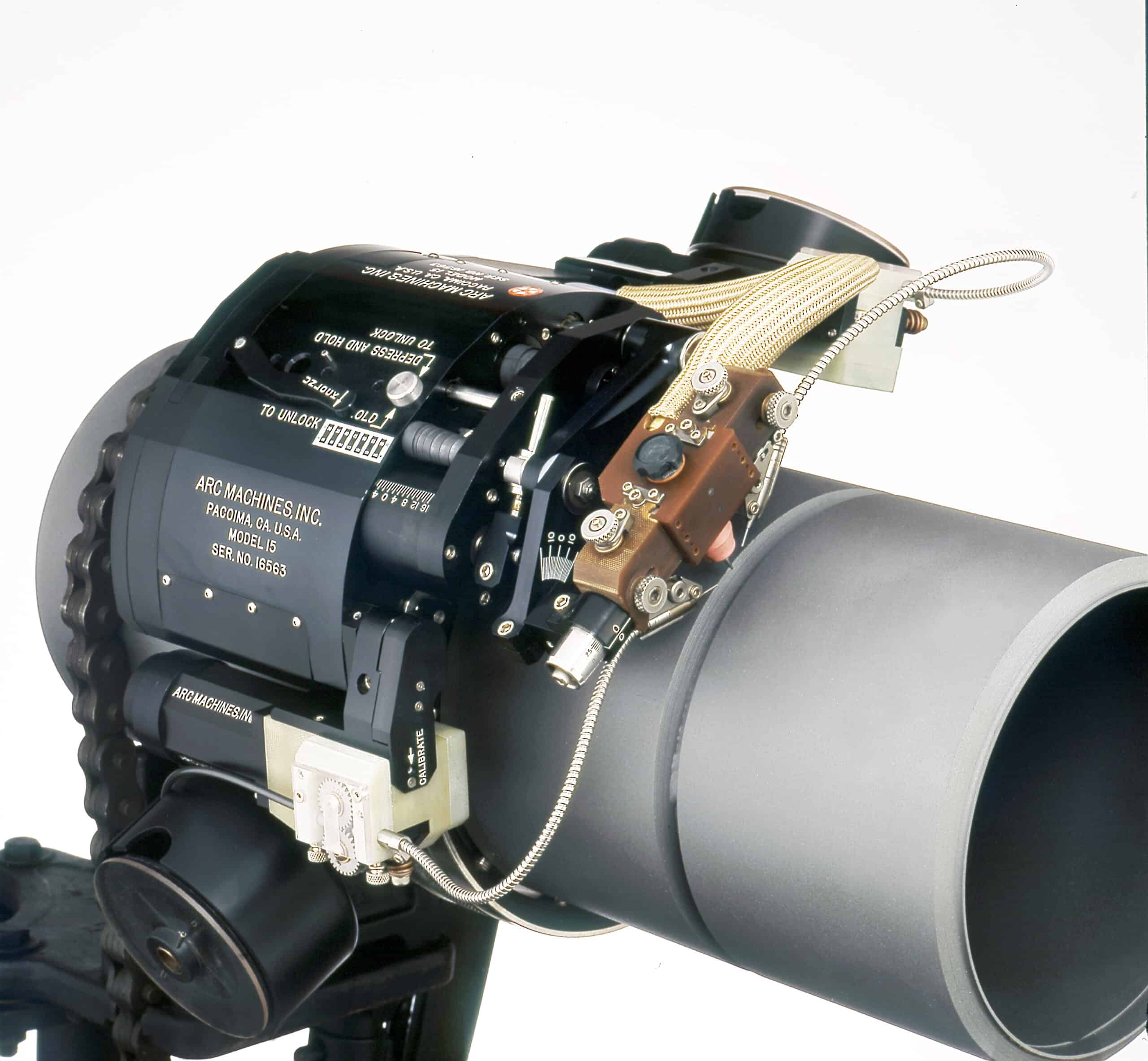

Arc Machines, Inc. pioneered many orbital welding technologies and continues to be a leader in weld data networking and remote orbital welding diagnostics and repair. For product inquiries, contact sales@arcmachines.com, and for service contact service@arcmachines.com. To develop a custom solution, contact us to arrange a meeting.