Nuclear power, a prominent energy source in the United States, contributes nearly 20% of total U.S. electricity generation. With 94 nuclear reactors operating across 28 states, the industry has increased its focus on the safety of nuclear components and structures to ensure public safety. One component that requires special attention is the nuclear steam generator.

Steam generators are an integral part of the nuclear reactor because they enable the conversion of water into steam using the heat produced and transferred from the reactor core. These generators have a significant role in regulating the flow and preventing core damage. Consequently, high-quality nuclear steam generator welding that assures strength, consistency, and purity is necessary. This article will discuss the function and importance of the nuclear reactor and how precision welding can address associated safety concerns.

The Function of a Nuclear Steam Generator

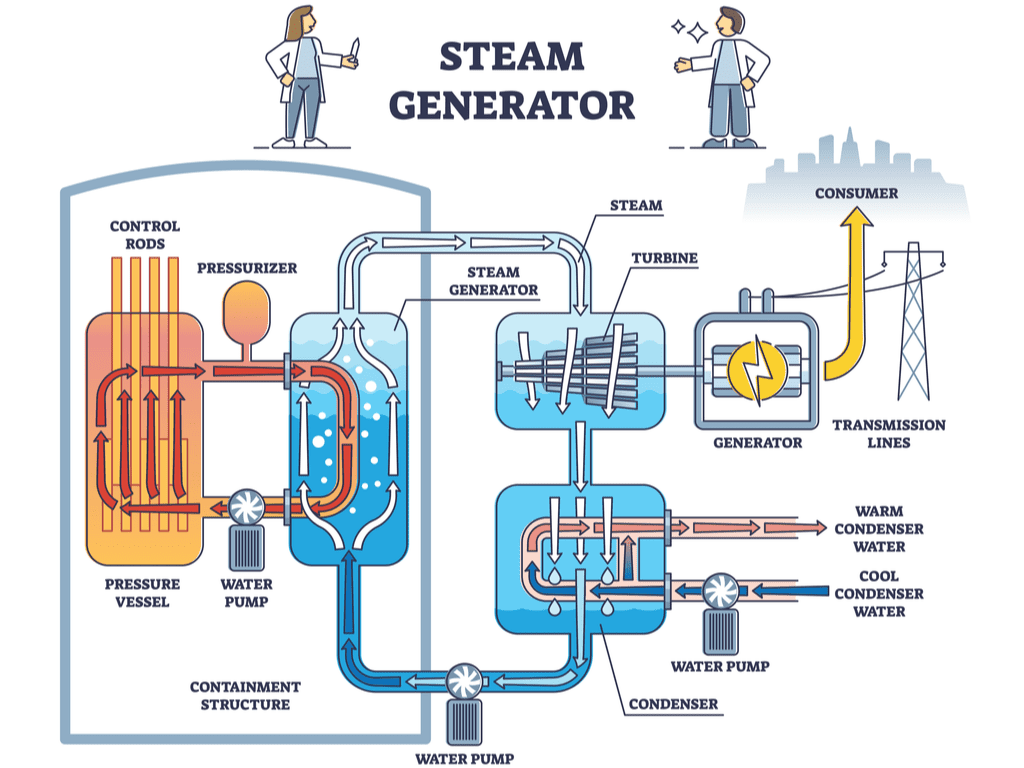

In nuclear power plants steam generators provide a similar function as heat exchangers. They are placed between primary and secondary loops as a heat transfer mediator in a pressurized water reactor. Water in the primary loop is highly pressurized to prevent boiling while heated with the help of fuel rods. This heat passes to the steam generator via a tube where heat is transferred to the secondary loop water (which is not pressurized and is allowed to boil), generating steam that drives the turbine.

The heat transfer mechanism cools the water in the primary loop that travels back to the reactor to reheat and continue the cycle. They can be compared, to an extent, with heat exchangers; however, the stakes are higher. A small defect in fabrication can lead to radiation transfer from irradiated to non-irradiated water.

Although nuclear plant construction follows established standards, exposure to high temperature and pressure cycles can cause degradation and lead to issues that include tube wear, stress-corrosion cracking (in the inner and outer diameter of the tube), fatigue cracking, and pitting. These defects in the steam generator also increase failure risks.

Concerns With Nuclear Steam Generator Welding

Flow-induced vibration, impurities, fissures, chemicals, and mechanical stresses are the leading causes of failure in steam generator tubes. In some cases, they may stem from the materials used for tubes and tubesheets. The tube sheet connection is also the point where most fatigue cracking or vibration-induced cracking occurs. Therefore, special care is required when welding these joints.

Achieving the best results during welding and fabrication requires welders to be aware of the following guidelines:

- Select the best tube alloy. In most cases, the established choice is Inconel 600 or 690.

- Choose a welding process that can overcome the challenges of tube and tubesheet welding applications. GTAW can be an ideal choice, given the control and shielding it offers to ensure deep weld penetration and weld purity.

- Opt for a welding machine that enables a level of precision that is difficult or impossible to achieve with manual welding.

- Make sure safety protocols are in place, as steam generator welding requires working with narrow tubes in tight spaces. This can be accomplished with flexible auto weld heads capable of welding in any position with minimal clearance.

Adapting Orbital Welding for Safe Operation

We discussed several nuclear steam generator welding challenges and the precision required to overcome those challenges. The necessary precision and consistency can be achieved with the help of orbital welding. For critical tube-to-tubesheet or sleeve welding, setting up a weld schedule for high-specification weld parameters can help solve complex welding requirements.

By selecting the right material, electrode, and welding equipment, manufacturers can address the concerns regarding nuclear steam generator welding and fabrication.

Arc Machines, Inc. is a leading supplier of advanced automated orbital welding equipment—including a wide range of weld heads and remote control pendants that ensure consistency and precision while maximizing safety in nuclear steam generator welding. For inquiries regarding these and other products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.