Welders, shop supervisors, and even accountants all have an interest in deciding how to calculate welding productivity and its impact on profitability. While calculating productivity can be a tricky exercise, welding shops with high-volume tube and pipe welding processes or similar types of repetitive repairs have the benefit of generating production metrics that can be used to calculate welding productivity and monitor process improvements. Common tube or pipe welding tasks such as butt, fusion, narrow groove, and tube-to-tubesheet can provide baseline data to help measure welding efficiency. Resultant metrics for calculating welding productivity might take into consideration:

- Units of production per day/week/month/quarter, depending on manufacturing volumes.

- Filler wire used, measured as wire weight or wire length consumed.

- Arc-on time as a percentage of an overall welding task, in hours per week/month/quarter.

- Scrap or rework rates.

Each of these metrics provides information on welding productivity, but no single, summary metric can accurately give insight into the more granular tasks that affect overall welding productivity. For this reason, it can be helpful to look at productivity from more than one point of view.

How to Calculate Welding Productivity for Pipe and Tube Projects

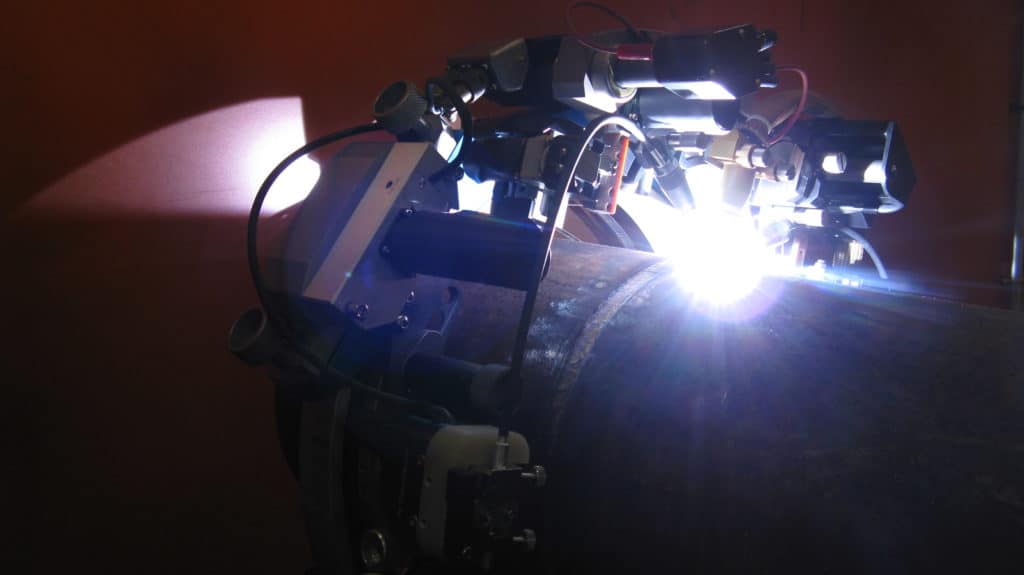

Since it has little need for operator intervention, the orbital welding process is ideal for high-quality, repeatable welding applications. By replacing manual processes with orbital welding methods, a wide range of industries has realized significant improvements in welding productivity. Although the calculations used to measure improvements in efficiency vary by shop, the benefits—quantitative and qualitative—are impressive.

Calculating Productivity Using Overall Process Time

One client of Arc Machines, a manufacturer of corrosion-resistant flow sensors used in food and beverage industries, calculates welding productivity based on the completion time for welding pressure flow sensors to piping. Each welding process varies, based on the number of sensor joints, pipe size, and type of piping the sensor will be welded to. The process used by this manufacturer involves combinations of:

- Two to four weld joints between a central casting containing the sensor with flanges on either side that connect with piping

- Joint sizes from two to 14 inches

- Schedule 80 pipe, carbon steel, stainless steel, duplex stainless steel, chrome-moly, and various nickel-based alloys, depending on corrosion requirements

By replacing a manual MIG welding process with an automated GTAW hot wire process, manual processes that would typically require a week to complete can now be completed in a single day. In the course of four years of production and thousands of welds, only two welds have been rejected. This low rejection level has contributed even further to the reduction of overall welding process time.

Calculating Productivity Using Man-Hours

Installing 6,000 linear feet of stainless steel piping (1/2-inch to 4 inches outer diameter (OD) and from 0.035 to 0.085 inches in wall thickness) in one brewery involved hundreds of fusion welds to ensure a smooth inner bead. Orbital welding techniques were employed for more than 90 percent of the welds. Modular weld heads were used to weld pipes, tees, and elbows varying in OD from 1 1/2 to 4 1/2 inches, with the typical two-inch OD weld taking 1 1/2 minutes of arc plus one minute of gas purge to complete. In comparison to the estimated number of man-hours to complete the job using manual welding techniques, orbital welding methods reduced man-hours by 15-20 percent and fabrication time by 50 percent, drastically increasing welding productivity.

How Orbital Welding Improves Productivity Rates

The ultimate goal of choosing a method to calculate welding productivity is to identify opportunities to improve the efficiency of the welding process using new techniques, technologies, and materials. Orbital welding is one technique which has the potential to provide significant improvements in productivity. Several individual tasks in a typical manual tube welding process present ideal opportunities for quantifiable improvements through the use of orbital welding.

- Alignment: Interchangeable orbital weld head cassette modules are designed for a wide range of tubing diameters. Clamps align and hold tubing or fittings prior to welding, eliminating the time required for manual tacking.

- Setup: Programmable orbital welding power supplies and controllers store weld schedules including details regarding pipe or fitting OD, wall thickness, material, weld type—tube, pipe, fittings, and welding variables—current, travel speed, pulsation, and time. The specific weld schedule stored in the controller’s memory is easily recalled when ready to weld.

- Weld time: Weld schedules provide precise control of welding processes, including pre- and post-purge gas flows, wire feed, electrode angle, arc distance, pulsation, and travel speed. Automated control using optimized welding parameters eliminates the variability of manual welding processes, minimizes arc time, and efficiently delivers consistent results without compromising quality.

- Changeovers/downtime: A wide assortment of modular weld heads and a library of welding schedules enable quick changeovers between various tube and pipe welding tasks to reduce downtime.

- Post-process rework: Consistent quality welds can significantly, if not completely, reduce the need for post-welding tasks.

Depending on the type of welding process being performed, time savings achieved by orbital welding techniques can range from minutes to hours, as in the case of major rework associated with a poor-quality manual weld. In high-volume applications or repetitive repair tasks, time savings in any one or more of these areas equate to significant gains when calculating welding productivity.

No Matter How You Calculate Productivity There’s Opportunity for Improvement

Every shop will have its own methods for determining how to calculate welding productivity across the many different welding projects it undertakes. Shops with high-volume welding processes have the benefit of monitoring production metrics to calculate productivity and identify areas for improvement using new technologies and techniques. As proven by the examples mentioned above, orbital welding solutions can make a significant impact on welding efficiency, regardless of how it is calculated.

In addition to improved productivity, orbital welding delivers consistent repeatable, quality welds, greatly reducing the time and expense associated with rework. Shops intent on improving welding productivity should seek out industry innovators like Arc Machines, Inc. With decades of experience in the industry, Arc Machines can provide solutions tailored to meet any orbital welding need.

Arc Machines, Inc. offers reliable, precision products designed to improve your welding productivity and quality. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.