Fusion welding is any welding technique that heats two pieces of material to their melting point and joins them together while molten. This term can be a subject of confusion as engineers may use it as a blanket term to refer to all types of arc welding (which is technically correct). Welders may have a narrower definition, using it to mean autogenous welding or TIG welding of tube or tube sheet without additional filler material.

When it comes to fusion welding for aerospace applications, the standards as defined by the American Welding Society D17.1 assume the more expansive definition of fusion welding. The standard provides exhaustive criteria for qualifying welders on all butt joints, t-joints, pipe positions, and pipe-to-plate positions on metals like steel, aluminum, nickel, magnesium, cobalt, titanium, and alloys thereof using both manual and mechanized gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and plasma arc welding (PAW). Essentially, it covers every fusion welding type that could conceivably be used in aerospace with an intense focus on qualifying welders and defining acceptance criteria for what they produce. Mechanizing, or automating, fusion welding for aerospace offers the opportunity to meet these standards more reliably while shortening the training time needed for welders.

The Need for Quality Fusion Welding in Aerospace

Aerospace has always been an exciting field with developments and potential developments that capture the imagination. However, since the mid-twentieth century, that excitement and potential has largely been speculative. Recently, that has changed with private companies pursuing electric flight, autonomous flight, supersonic flight, and even space flight.

Simultaneously as the number of companies working in aerospace has expanded, a shortage of welders and other skilled trades has developed—which is becoming more acute as baby boomers age out of the workforce. This is an especially pressing need in the realm of aerospace as the specifications for welds in this industry are demanding, and there is very little leeway allowed. The need for qualified aerospace welders is increasing, and the number of qualified welders available has declined. Welding automation, like orbital GTAW, can step into this gap and meet the standards for fusion welding for aerospace applications.

Orbital Fusion Welding for Aerospace Applications

Orbital welding is a welding technique whose history is intimately linked with aerospace. It began with the boundary-pushing x-planes in the nineteen-fifties and the need to manufacture fuel lines that wouldn’t leak under extreme pressure changes. Since then, orbital welding has had long and successful use in fusion welding for aerospace applications. Specifically, it has been used to weld:

- Fuel Lines and Fitting: Lines made of materials like aluminum, steel, or titanium that are responsible for the delivery of fuel from fuel storage to the aircraft powerplant. Fittings such as couplings, adaptors, and valves are frequently welded into these lines as well as direct tube-to-tube welds.

- Hydraulic Lines and Fittings: Responsible for transmitting hydraulic fluid, which can be corrosive to brakes, landing gear, and control surfaces. Lines and fitting must be able to resist pressure extremes inside and out without leaking.

- Vacuum Lines and Fittings: Typically made of materials such as rubber, plastic, or aluminum, and may include fittings such as check valves, vacuum regulators, and vacuum pumps. Vacuum lines and fittings must be able to maintain a tight seal and withstand temperature and pressure changes without leaking.

These are vital systems that need to hold fluids or maintain a lack of gases during changes of elevations that radically change the external pressure vs. that which is contained within the lines. These systems require a highly skilled welder—or orbital GTAW.

Orbital GTAW meets the exacting demands of this industry by automating the process of welding tubes and pipes. In orbital welding, the torch assembly is mounted to a track around the pipe or tube, and all aspects of the weld geometry, like arc length, travel speed, and oscillation, are automated. The result is a weld that is consistently performed over and over. So long as the parameter meets acceptable criteria, the weld setup is performed correctly, and the weld head and power supply are in good condition, an acceptable weld will be produced. This results in very consistent welds that can be repeated over and over. The importance of this in meeting fusion welding for aerospace applications standards cannot be overstated.

Why Orbital Welding is Preferred in Aerospace

In fusion welding for aerospace applications, consistency is the objective. The required strength of the weld and having that strength last through recurring pressure changes and high-intensity vibration is directly correlated to consistently fusing the metal the entire length and depth of the joint. Any discontinuity, no matter how minor, can form a stress point that can potentially lead to joint failure. The advantage of automating fusion welding for aerospace applications is that it removes the most inconsistent element—the welder. The welder can grow tired, slip, or otherwise make an error that can compromise a weld.

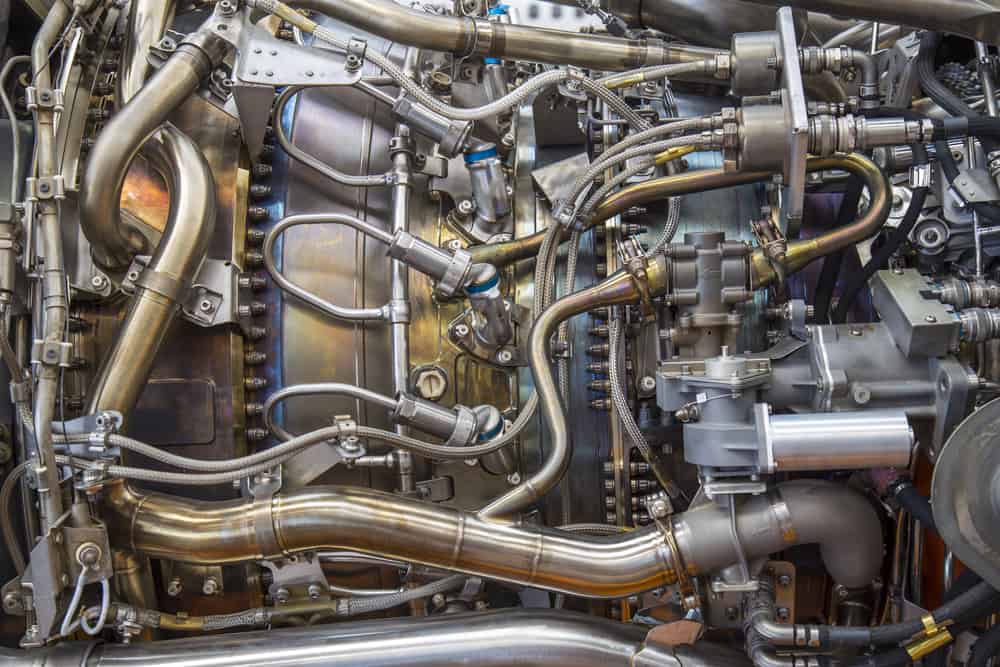

This does not make orbital GTAW welding infallible, but it does mean that it can provide highly precise and repeatable welds that consistently meet the needed standards of fusion welding for aerospace applications. A weld head is much smaller than a fully kitted-out welder and can fit into smaller spaces. This is a distinct advantage when welding something like a hydraulic line in the cramped confines of an aircraft wing or any one of the nests of fuel lines found on the average rocket motor. It also allows for welding to take place in atmospherically closed environments and is an important consideration for welding metals like titanium, where even slight exposure to the atmosphere can seriously compromise the weld.

The standard for fusion welding for aerospace applications, AWS D17.1, is more concerned with ensuring that welders are qualified to meet the welding criteria developed by project engineers than setting actual parameters for individual welds. Orbital welding plays a critical role in meeting these standards using cutting-edge technology and automation. If you are looking for assistance with fusion welding for aerospace applications, AMI can help.

Fusion Welding For Aerospace Applications With AMI

Arc Machines, Inc. is a long-time industry leader in orbital welding solutions in fusion welding for aerospace applications. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Contact us to arrange a meeting. Arc Machines welcomes the opportunity to discuss your specific needs.