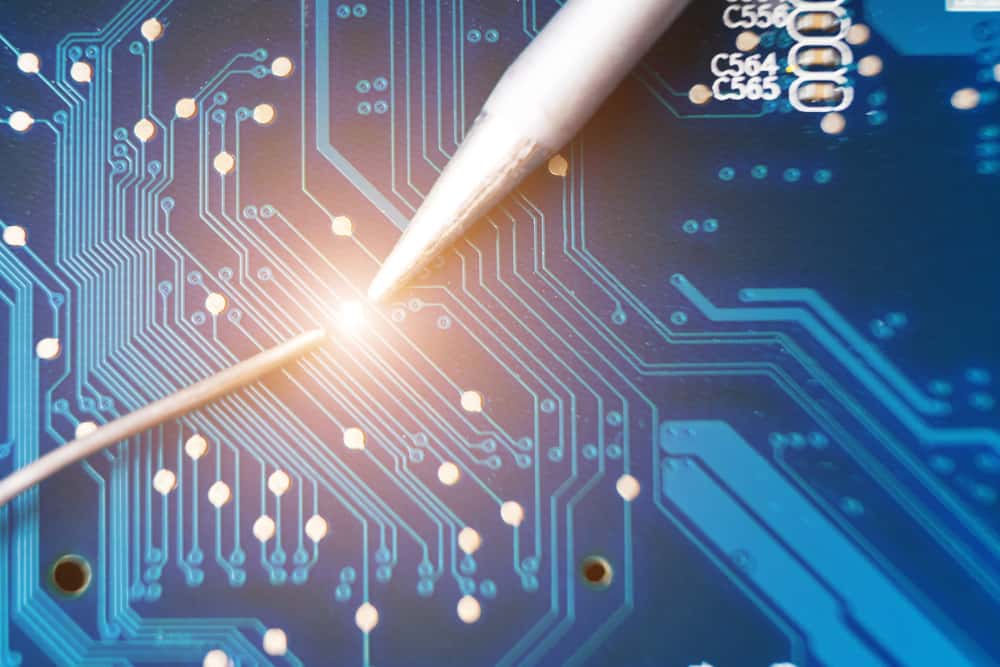

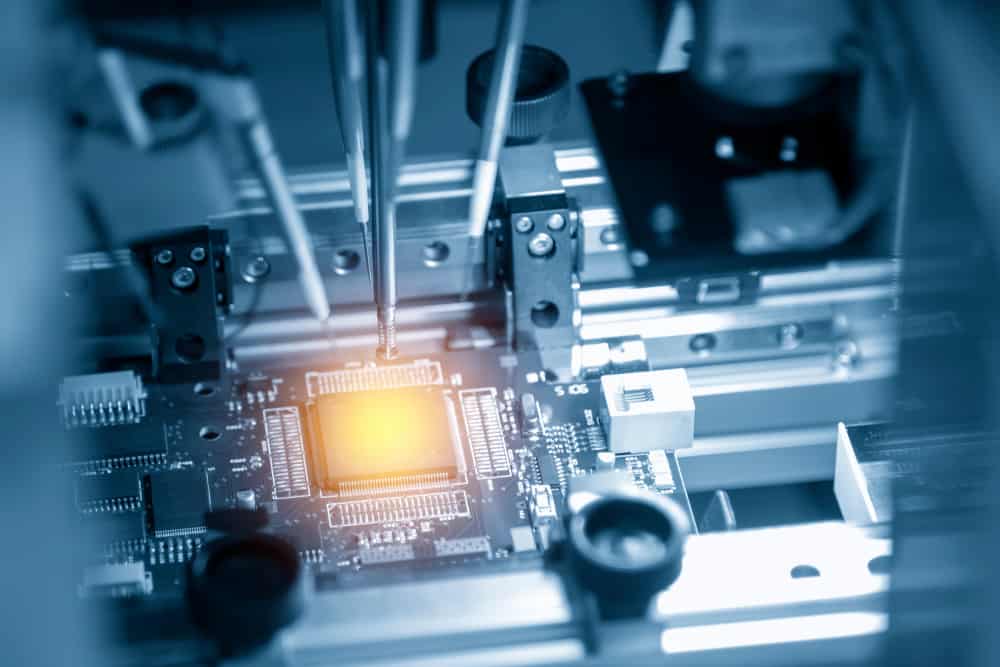

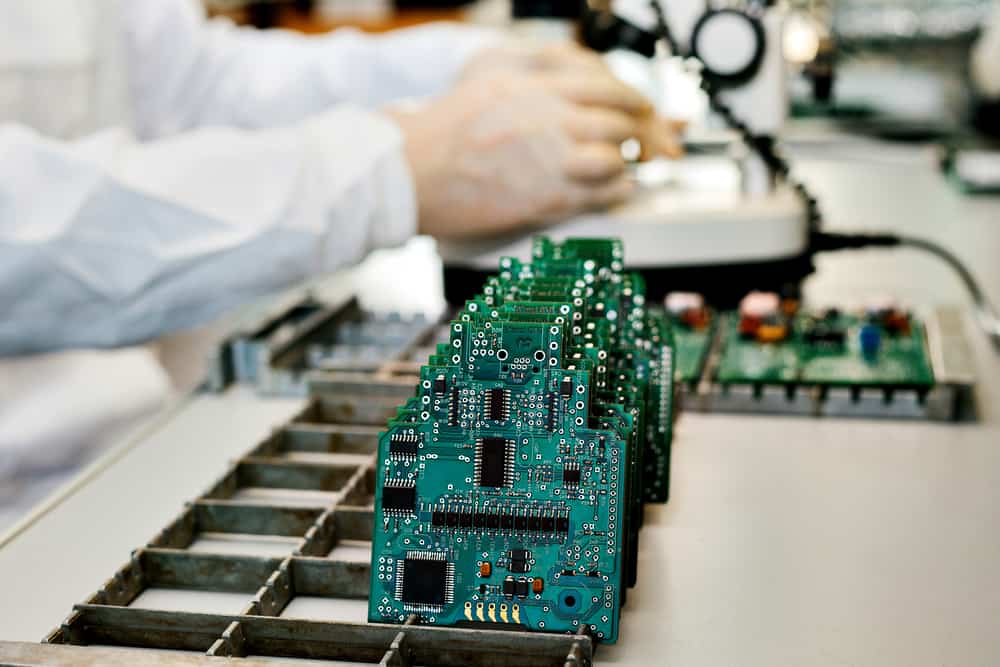

Semiconductor manufacturing has become more complex, with today’s chips requiring nanometer-level precision. Additionally, the range of exotic materials used in the manufacturing process, alongwith the specialized skills and required technology to create a semiconductor chip have also expanded. As global demand increases, manufacturers can struggle to adhere to quality standards….