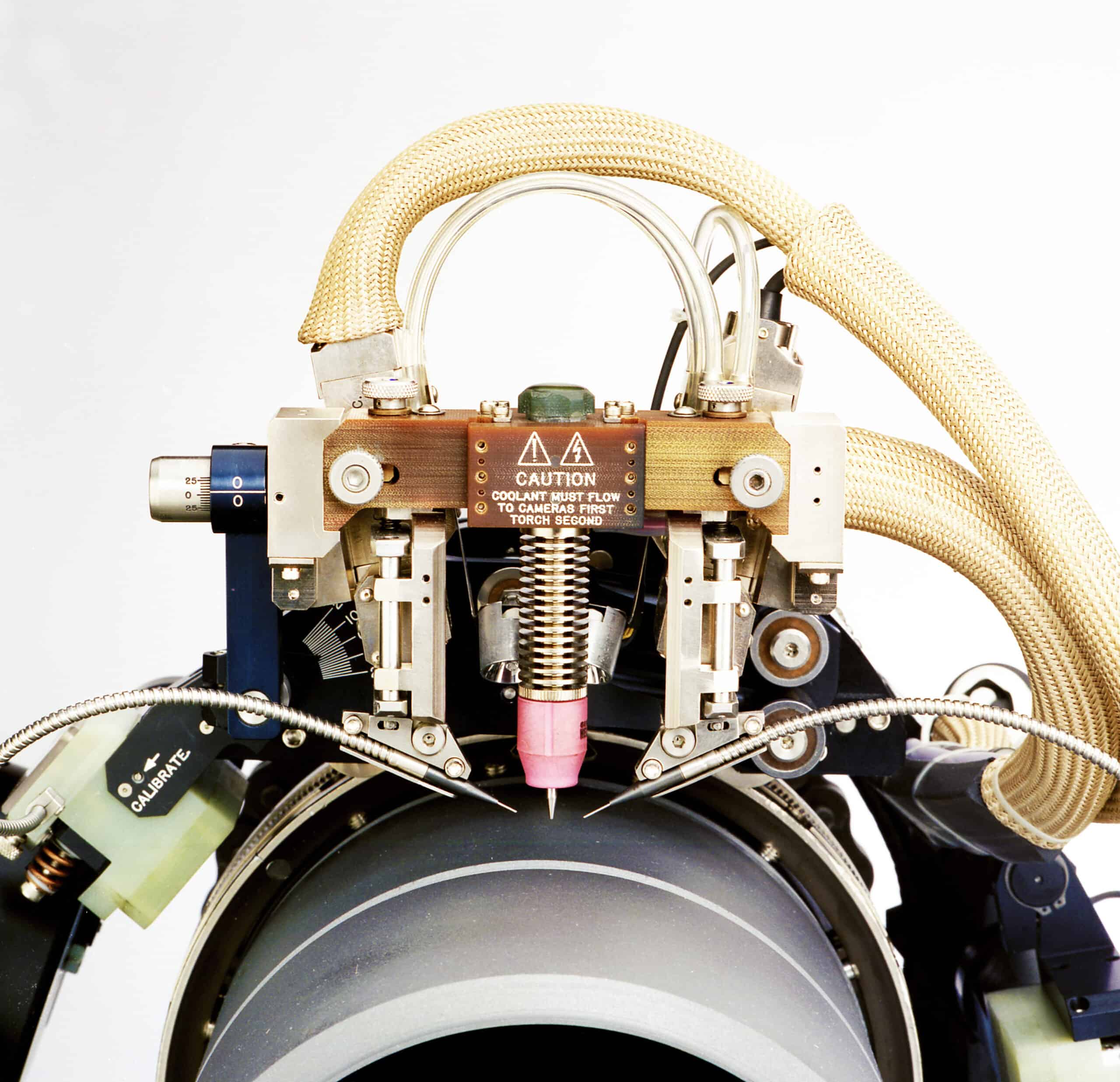

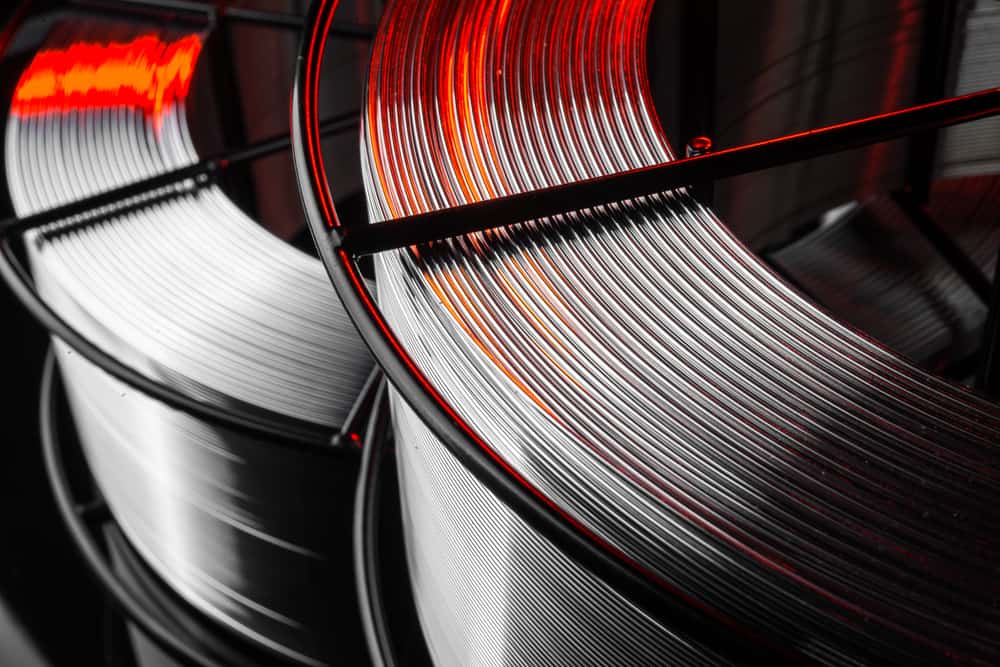

As the scale of global pipeline construction continues to increase, industries are looking for advanced and effective ways to ensure pipe welds meet and exceed standards while providing a longer service life. But overcoming pipe welding challenges—such heavy wall welding, welding in curved areas, and ensuring proper alignment in the…