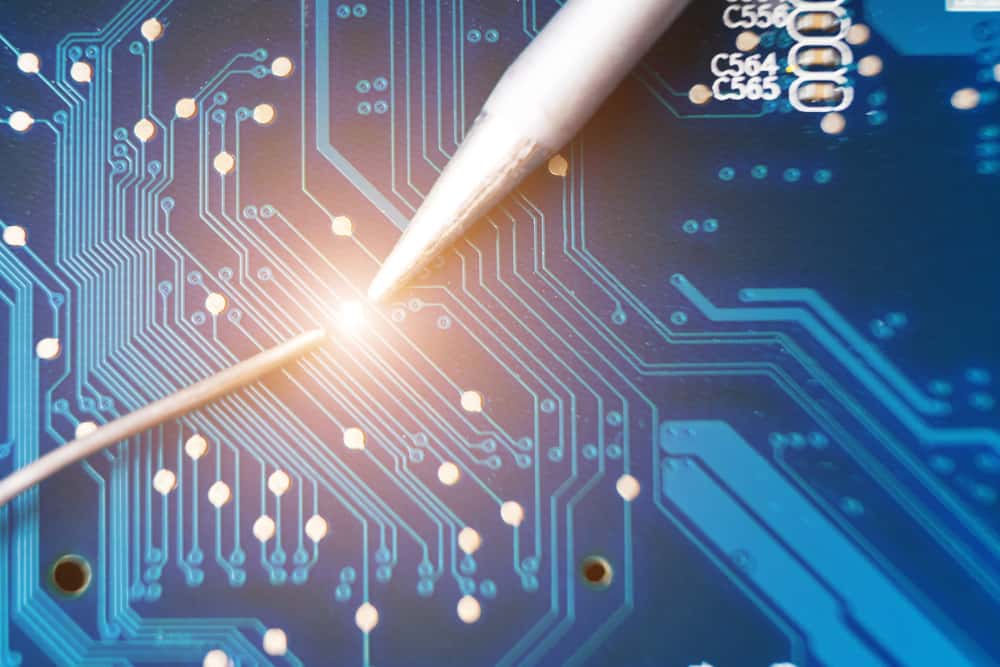

One of the primary reasons I pursued mechanical and electrical technology and associated occupations was its reliance on mathematics and sciences such as chemistry and physics. In contrast to other fields of study, the principles of science and mathematics reflect its foundation in consistent and repeatable laws and theorems. If…