Some things happen like clockwork. Now, I have nothing against groundhogs, but there are other more reliable indicators that warm weather is arriving, such as the sprouting of leaves and the sighting of birds. Almost as predictable is the announcement of a new and improved feeder mechanism for weed eaters. I will admit that progress is being made; however, completely preventing the plastic line of these tools from jamming seems to be an almost insurmountable task.

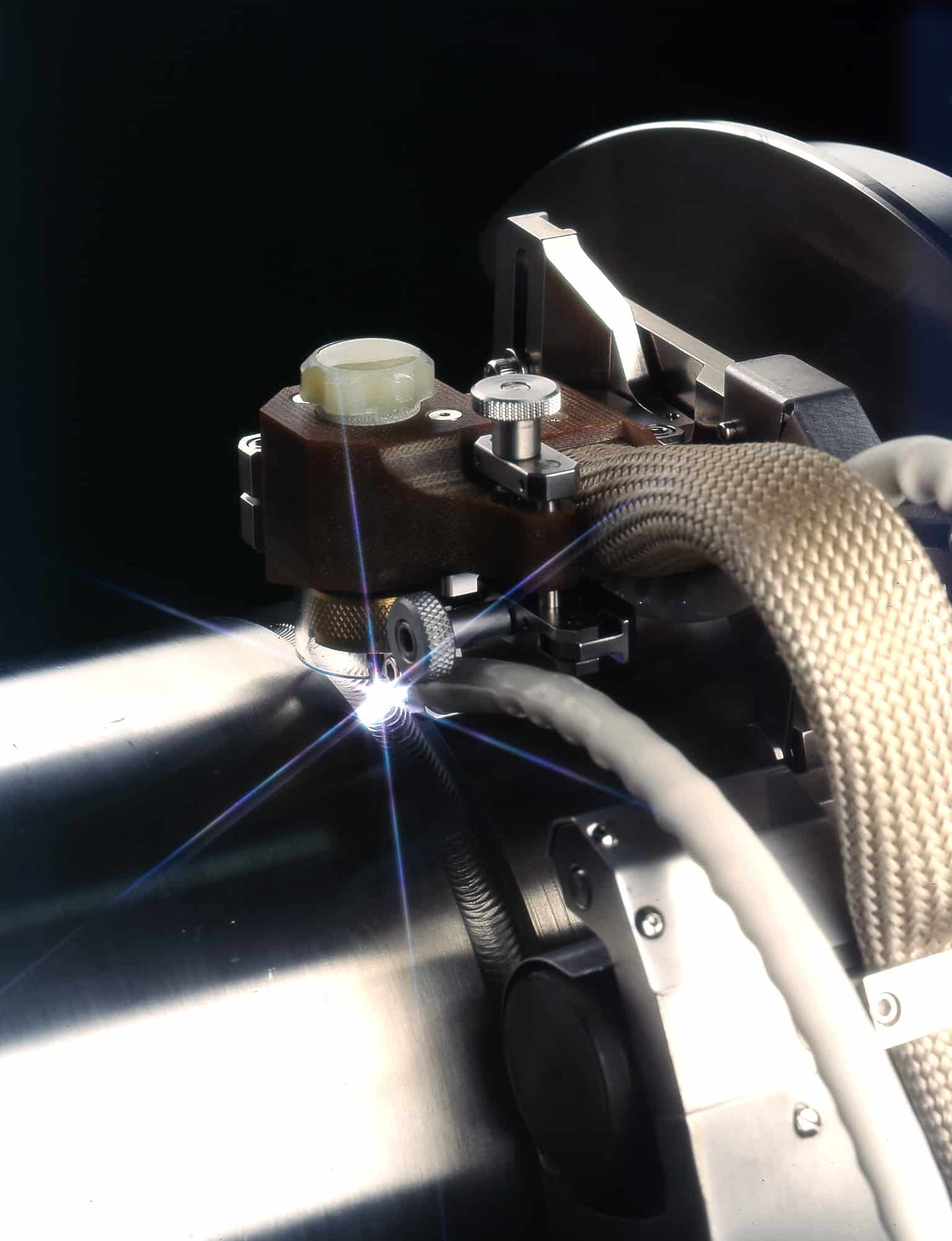

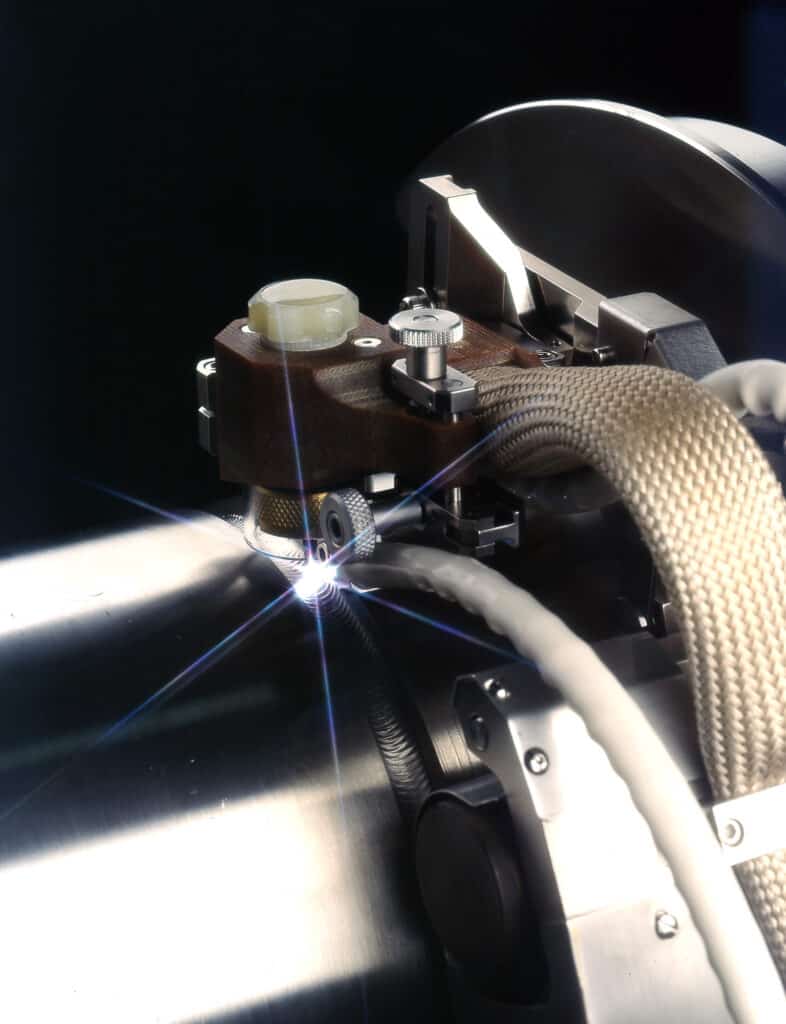

For manual welding, similar frustrations over jamming exist for wire feeding in Metal Inert Gas (MIG) welding also known as Gas Metal Arc Welding (GMAW), or in Flux Core Arc welding (FCAW). It may be due to tip size, the liner, or the gun itself. Mechanized welding processes, like orbital welding, are safer and more efficient than manual welding, and provide more controlled weld feed operation.

Automated wire feed as used for orbital welding processes is indeed an improvement over manual feeder operation; however, wire feed welder jamming can and does occur. Having to stop a job to fix a wire feed jamming issue is a minor annoyance in most manual welding. However, it can cause significant downtime in the sophisticated applications orbital welding is used for. The frequency and severity of these occurrences can be minimized, as we discuss below.

Typical Causes of Wire Feed Welder Jamming

A jammed feeder wire is typically caused by a simple error or wear. In orbital welding, it can cause significant problems, including lengthy downtime for rework or the need to replace expensive specialty metals or exotic alloys. It is best if it is caught early before work begins, and most of the causes can be checked and remedied as part of a pre-shift arc welding machine 5-minute daily inspection checklist. These should be the first things considered if an error is encountered. However, there are some issues that can cause wire feed welder jamming that may be caused by errors in either machine settings or the choice of materials.

Wire Feed Speed Interference

In addition to using the wrong diameter wire, which impacts the melting temperature, speed is also a primary concern that affects weld quality, as well as feed wire flow. It is a basic procedure to check machine wire speed settings against the provided welding parameters. However, loose connections, wear of the machine, or even something as simple as a worn feed liner can cause potential wire feed issues. These should be checked before welding begins and double-checked if an error occurs during welding. If machine settings are correct, all connections are firm, and no part of the wire feed has visible wear, it could be a calibration issue.

Incorrect Wire Feed Diameters

A constant wire feed operation is essential to create consistent, precise welds. This is critically important in the high-specification applications where orbital welding is used. The use of the incorrect wire can cause wire feed jams through either the wire diameter being too large for the wire feed liner and mechanisms causing it to drag. Conversely, if the wire is too small for the application, it may cause the wire to melt back into the mechanism due to overheating or allow for kinking of the wire that can impede the feed. Therefore, using the correct wire diameter is just as important as using the correct metal type for wire feed welding.

Inadequate Clearance for Wire

An issue that is unique to orbital welding that can cause wire feed welder jamming is inadequate clearance for the wire feed mechanism to operate. One of the many advantages of orbital welding is that it can weld tubes or pipes in inaccessible places with little available space. Weld heads and wire feeds can be configured to fit into smaller spaces still. This can potentially cause constrictions between the wire spool and the feed mechanism that impede the smooth feeding of consumable wire.

Incorrect Wire Heater Settings for the Environment

An additional unique consideration specific to orbital welding is preheating of the wire using an additional wire heater. This is used in fixed position pipe cladding processes to increase the deposition speed of the material. The actual temperature of the wire as it is fed into the molten puddle can be affected by the surrounding environment with especially cold or hot conditions. This causes the wire temperature to be beyond the parameters called for in welding specifications. If the wire is too cold, this can cause wire feed welder jamming. The temperature can be adjusted as needed following test welding at the beginning of a shift.

How to Prevent Wire Feed Jamming

Most welding machine problems can be avoided by following a well-planned maintenance schedule that includes short term and long-range preventive maintenance. Likewise, the risk for wire feed welder jamming can be greatly reduced by preventive measures, as listed below.

- Select the best feed wire material for the welding process.

- Make sure the feed wire size matches the liner and mechanism size.

- Perform test welds prior to the beginning of a shift to verify machine operation.

- Utilize a welding monitoring system to check for degradation in weld quality.

- Note any changes in motor function that may indicate problems, such as sound.

- Inspect the wire feeder mechanism on a routine basis for signs of wear.

If taken, the preventive steps above will save you from the headache of interruptions and equipment downtime. If a jam does happen, it can usually be easily fixed without tearing the mechanism down, as the reel itself is the most likely culprit. If it appears to be more complicated, contact your support team for guidance.

Arc Machines, Inc. has been an industry leader in delivering high-quality welding equipment for decades, including wire feed mechanisms. In addition to supplying the products for advanced welding technology, we also provide personalized service at several tiers, including remote support, to meet your needs and ensure that you stay working instead of losing productivity. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.