Stainless steel is a critical material in a range of industries. Without it, the dairy, food, and beverage industry would have great difficulty in keeping food safe while producing it in industrial quantities. Similarly, the chemical and biopharmaceutical would find it impossible, or at least uneconomical, to operate as they presently do. Stainless steel is a vital material and, in many ways, a real-life example of a wonder material.

It should come as no surprise that there are many types of stainless steel welding. A material with use in everything from dental crowns to rockets has equally wide use in industry. As a consequence, the need to weld stainless steel has resulted in a plethora of types of stainless steel welding.

The Types of Stainless Steel Welding

Stainless steel is notoriously prone to heat distortion during welding. This is a larger issue when dealing with thin-walled materials or materials where alignment is especially important, like stainless steel tube welding. Certain types of stainless steel welding mitigate this issue by minimizing heat input, but do so at the price of speed. These processes become prohibitive in welding thick-walled materials, as they extend the time to completion. Others make quick work of welding thick-walled stainless steel, but cannot be used on thin-walled materials. An overview of these different processes can be seen in the table below.

| Types of Stainless Steel Welding | ||

| Process | Visual | Description |

| Shielded Metal Arc Welding(SMAW) |  |

Welding using a flux-coated (shielded) electrode. Electrodes are available for most types of stainless steel. SMAW can weld austenitic, ferritic, and martensitic stainless steels with the proper choice of electrode. |

| Submerged Arc Welding (SAW) |  |

Welding by submerging the workpiece, weldhead, and consumable electrode in a thick coating of flux dropped down from a hopper. The process can be used on very thick pieces of metal of a half-inch and above thickness. The pipe is rotated beneath the welder. As the process is gravity-fed, welding is restricted to the flat position or 1G pipe welding. |

| Gas Metal Arc Welding (GMAW or MIG) |  |

GMAW is a versatile welding process that can be used in any position. Its speed makes it an excellent choice for finishing thick materials that require multiple passes. The low voltage arc starts that are possible with GMAW also make it a good choice for welding thin stainless steel and minimizing distortion due to heat input. |

| Flux Core Arc Welding (FCAW) |  |

Flux core is essentially wire feed welding with similar arc start and characteristics as SMAW. Arc voltage needs to be high to start and sustain the arc through the flux. The resultant heat limits how thin the stainless steel that can be welded with FCAW is, and the heat input can lead to distortion. However, this is a very versatile welding process that can be used nearly anywhere. |

| Gas Tungsten Arc Welding (GTAW or TIG) |  |

GTAW welds stainless steel using a non-consumable tungsten electrode shielded by argon gas. This provides very clean and pure welds with exceptional strength. GTAW can also weld stainless steel in any position. The process does, however, require a substantial amount of time and setup in order to reach these very high standards. |

Complicating the choice of stainless steel welding types still further is that there are different types of stainless steel, each with its own properties. In most daily applications, the differences in stainless steel due to these properties are largely immaterial. However, in very high-specification welding for industries like petrochem, biopharmaceuticals, and thermal power generation, these unique properties and how they react to different types of stainless steel welding can matter greatly.

Welding Different Types of Stainless Steel

Different alloys like 316 L vs. 316 or 304 are pretty common knowledge. Less common is knowledge of the differences between ferritic vs. austenitic stainless steels or ferritic vs. austenitic vs. martensitic. A rough breakdown of how these different types of stainless steel function is below.

Ferritic Stainless Steel

- Predominantly composed of the ferrite phase, which has a body-centered cubic crystal structure.

- Magnetic in all conditions, which can be an advantage or a disadvantage depending on the application.

- Offers good corrosion resistance, especially in oxidizing environments.

- Not as ductile as austenitic stainless steel, limiting its formability and weldability.

Austenitic Stainless Steel

- Predominantly composed of the austenite phase, which has a face-centered cubic crystal structure.

- Non-magnetic in the annealed (softened) state, but some magnetic response can be observed when cold-worked or welded.

- Relatively low carbon content, typically below 0.08%.

- Excellent corrosion resistance, particularly in acidic and chloride environments.

- High ductility and excellent formability, making it suitable for a wide range of applications.

Martensitic Stainless Steel

- Has a martensitic crystal structure characterized by high hardness and strength.

- Magnetic in all conditions due to iron and the martensitic phase.

- Good corrosion resistance, but not as resistant as ferritic or austenitic stainless steels.

- High carbon content and the martensitic state allows for hardness and wear resistance but reduces ductility.

- Martensitic stainless steels are deliberately induced only at the surface level to resist wear and corrosion but maintain ductility across the rest of the workpiece.

The different properties of these metals need to be accounted for in selecting a welding process and the fill materials used during welding. The choice of stainless steel electrode for SMAW welding needs to account for both the position of welding and whether the workpiece will be ferritic or austenitic. Weld positioning also plays a substantial role in the choice of fill material as elements like silicon in the fill material can enhance flow, allowing greater penetration in the flat but possibly interfering with fusion in the vertical and overhead positions.

Gas-shielded arc welding processes like GTAW and GMAW can have these interactions. However, they are, to an extent, reduced due to the fact that the removal of shielding fluxes removes some of the potential chemical interactions between stainless steel and other elements.

GMAW and GTAW Types of Stainless Steel Welding

Both GMAW and GTAW allow for starting and sustaining arcs at lower voltages compared to other welding processes. This minimizes heat distortion. As they are gas-shielded, chemical interactions are also reduced. These are significant advantages in ensuring consistent welds and reliably getting those consistent results.

They are, however, not without their disadvantages. GMAW can have issues with fusion and penetration. GTAW provides high-quality welds with excellent fusion in all regards. As previously mentioned, though, it is a very slow process, assuming that a skilled operator is available. GTAW has a very high bar for qualification and certification of acceptable welds.

There are solutions available for GTAW, though. Automation has allowed for the creation of welds far above what even skilled manual welders can produce in shorter time frames. Hot wire GTAW—which preheats the fill material before it enters the puddle—enhances the speed of deposition and welding overall, although it still is a relatively slow process compared to other welding types. A GTAW root pass combined with GMAW cap passes can provide the optimum combination of types of stainless steel welding, producing high-quality welds at speed.

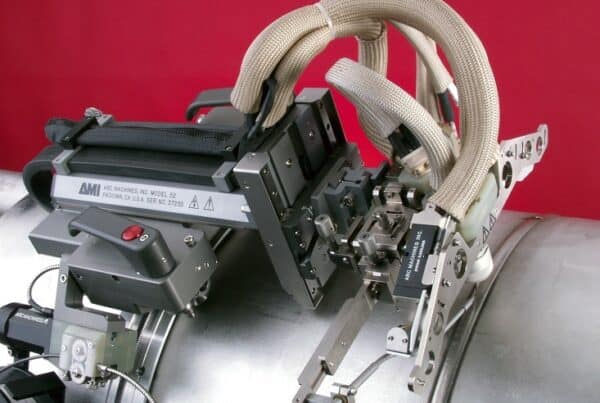

Arc Machines, Inc. provides high-quality orbital welding heads and power supplies for GTAW stainless steel welding. Contact us to discuss your specific needs.