The welding of pipe and tube is one of the most challenging types of welding. The need to move an electrode around the entire circumference of a pipe or tube complicates manual welding, as the welder needs to shift positions multiple times to complete the weld. This makes it extremely difficult to meet the needs of high purity or high specification welding and adds an additional challenge to an already difficult welding process like gas tungsten arc welding (GTAW), also known as tungsten inert gas or TIG welding.

The solution for many of the most demanding industries is to automate the process of welding tubes and pipes—a process known as orbital welding. An orbital TIG welding system automates the most difficult aspects of the welding process, allowing the operator to focus on delivering quality results.

What Is an Orbital TIG Welding System?

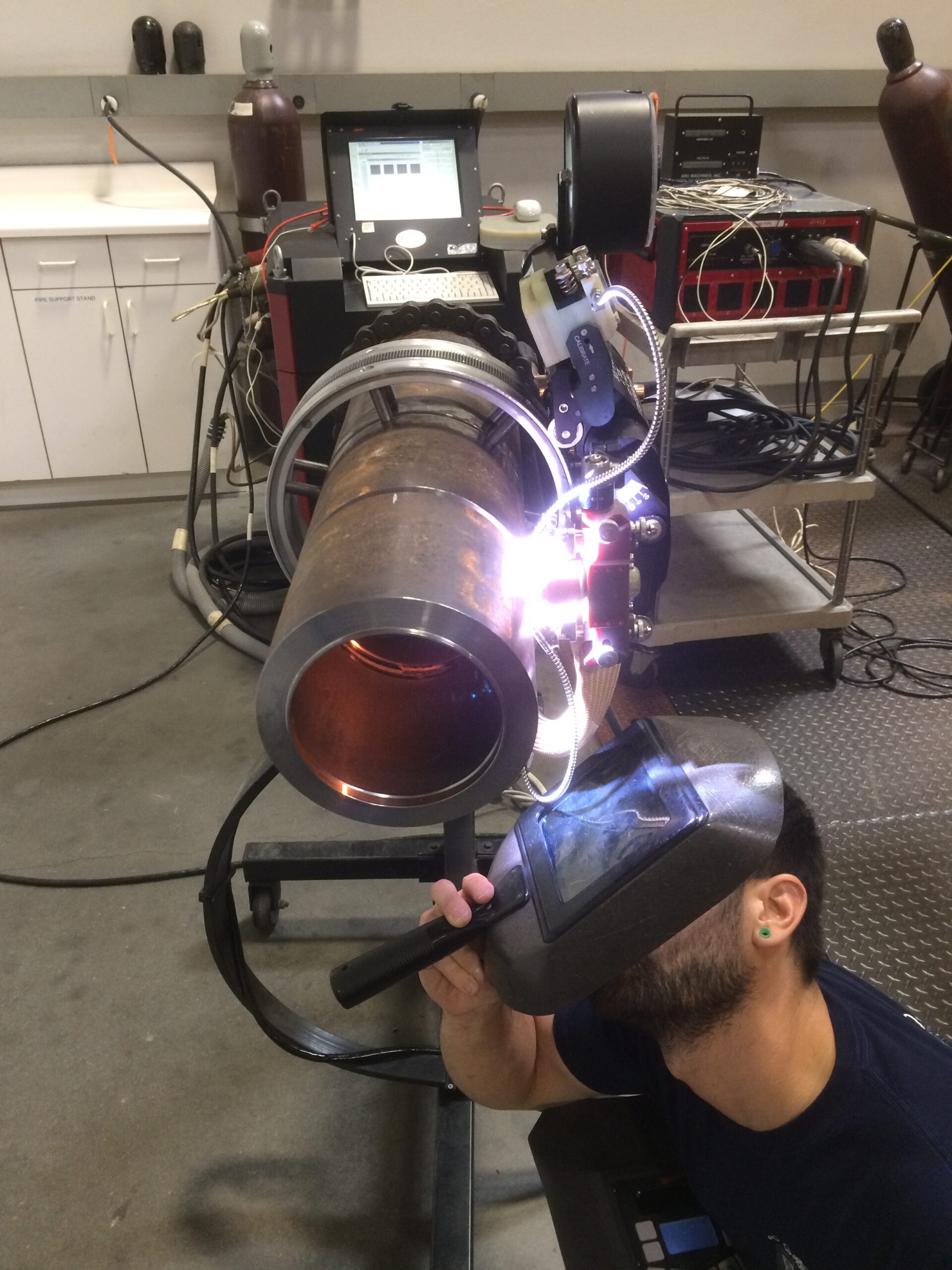

Orbital welding is an arc welding technique in which a welding electrode is rotated around a workpiece that remains fixed. In other words, the weld head “orbits” the workpiece. The history and uses of orbital welding have been extensive, including most arc processes except shielded metal arc welding, also known as SMAW or stick welding. The constantly shrinking nature of the consumable electrode, as welding progresses, makes automating SMAW welding prohibitively difficult. However, automated or semi-automated orbital welding systems can be found for flux core arc welding (FCAW), gas metal arc welding (GMAW), as well as gas tungsten arc welding (GTAW). GTAW, or TIG, is actually the original orbital welding system that was designed in the 1940s to meet the demands of NASA’s X-plane program.

These orbital TIG welding systems are a multicomponent system that is designed to weld either the interior or exterior circumference of a pipe or tube using a tungsten electrode in a specially adapted weld head. The process is used for autogenous tube welding, tube to tube sheet welding, and even big bore pipe welding. Although large diameter pipe welding often involves additional welding processes. Orbital TIG welding is a slow process, and the larger the diameter of the pipe, the longer it can take. Hot wire GTAW can speed up deposition rates. Another option is to use an orbital TIG welding system to complete the most critical root pass and complete cap passes with another process like GMAW or FCAW. These additional welding processes can significantly speed up the production of large diameter pipe welding or fabrication of other similarly large diameter or thick-walled materials like welding pressure vessels.

An orbital TIG welding system is, of course, a system. What these systems can weld is largely determined by the capacity not only of the weld head but also the power supply. However, the capabilities of these systems can be expanded through the use of additional add-on elements.

Weldheads for Orbital TIG Welding Systems

Orbital TIG welding systems are multipart systems. At the very least, they will consist of a power supply and a weld head. The weld heads are where the most apparent differences are to be found. Orbital TIG produces very high-quality welds, and there is a need for high-quality welding in nearly every industry. The result has been a proliferation of a wide variety of weld heads meant for unique purposes. A selection of the most common weld heads for an orbital tig welding system are:

- Closed Weld Heads: Closed weld heads are made for autogenous welding of smaller-diameter tubing. The body of these weld heads wraps around the whole circumference of the workpiece, and the weld head body itself helps contain shielding gases. These weld heads are among the most automated welding available and can weld with minimal supervision.

- Tube sheet Weld Heads: Like closed weld heads, tube to tube sheet weld heads are made for autogenous welds. However, unlike closed weld heads, these orbital TIG systems are largely open and are more immediately recognizable as TIG arc welding systems.

- Open Weld heads: These are the most diverse range of weld heads available for a TIG orbital welding system. These weld heads are meant for welding large diameter and thick-walled pipe. In order to accommodate these large pipes, open weld heads are modular systems that mount to tracks. These tracks can be mounted to pipes of any size or can even be adapted for welding in the flat, horizontal, or vertical.

- Interior Diameter Heads: Interior diameter or I.D. weld heads are designed for welding the inner circumference of a pipe or tube. These weld heads can be used to join materials, but they are just as often used to clad the interior of pipes with more resistant or stronger materials.

These categories of weld heads aren’t necessarily as cut and dried as they may first appear. There is a wide range of different purpose-built weld heads. For example, a Model 34 weld head is a very specific type of open weld head that was made for sealing nuclear waste canisters. Even though it is technically an open weld head, it has a more superficial resemblance to a closed weld head due to being designed specifically for a certain type of canister. It can also be adapted to other purposes, so its design has a degree of modularity.

As sophisticated and diverse as orbital weld heads are, they are actually the simplest part of an orbital TIG welding system. Modern power supplies are substantially more than just a transformer that puts high voltage power through to the weld head. They are sophisticated programmable control units that control not only the weld head but also gas, electrical current, and everything else that goes to the weld head.

Orbital TIG Welding Power Supplies

A typical arc welding power supply is not a simple system. At the very least, it converts the electrical current coming into the polarity or current type that is needed to complete the weld. In wire feed arc welding processes like GMAW and FCAW, it includes the mechanical systems necessary to feed the wires. In processes like GMAW and GTAW, where gas shielding is used, a power supply also includes gas feeds and may include ways of digitally adjusting the gas flow rate.

Orbital welding power supplies must manage all of the above, plus make allowances for programming that will guide the weld heads through their welding procedures—likely to include multi-dimensional movement, changing heat controls, and wire speed feed through different parts of the weld’s orbit. Higher heat is needed to ensure fusion at the weld’s start, and faster wire speeds are potentially needed while the weld head moves through the overhead position. The power supply of an orbital TIG welding system is effectively a welding robot’s brain but requires even more adaptability in both software and hardware.

In addition to running weld heads from the power supply’s manufacturer, there is an increasing expectation that an orbital welding power supply should also be able to operate weld heads from different manufacturers. In addition to this, there are also a variety of extra add-ons that might be required to complete an acceptable orbital TIG welding parameter successfully. These include things like liquid cooling systems for heavy-duty weld heads, hotwire heating systems that increase the speed of welding and even additional systems like purge sensors that help ensure that the interior space of a pipe or tube has been completely purged before welding begins. In this day and age, analytics and even the ability to help adjust welding parameters as needed are also something that welding power supplies need to account for.

Arc Machines Inc. provides complete orbital TIG welding systems for tube, tube sheet, and pipe welding, including weld heads, power supplies, purge sensors, and hot wire GTAW and weld head coolant systems. Our Model 217 and Model 317 provide complete support for our orbital welding systems and can even support competitor weld heads if needed.

Contact us to find out more about Arc Machines products to help you get the job done.