In welding, precision and efficiency are key factors that influence the quality and durability of the output. Among the different welding techniques, welders prefer gas tungsten arc welding (GTAW) and plasma arc welding (GTAW-P or PAW) to ensure accuracy and control in the fusion process. The similarities between the two techniques, mostly based upon the use of non-consumable electrodes and inert shielding, are the base on which these approaches produce clean and quality welds. However, some significant differences between each welding approach make them unique for varying types of welding applications.

So today, we will compare GTAW vs. GTAW-P(PAW) and explore the scenarios where each approach is appropriate.

GTAW vs. GTAW-P: Exploring The Differences

In the sections below, we will take a deep dive into each and explore the similarities and differences in GTAW vs. GTAW-P.

GTAW

GTAW, also known as tungsten inert gas (TIG), is a welding process that utilizes a non-consumable tungsten electrode to initiate an arc with the workpiece. The arc generates intense heat and melts the base metal to create fusion. The inert shielding gas provides a protective environment to keep the contaminants away from the weld pool, facilitating the creation of a clean weld joint.

One key feature of the GTAW process is its exceptional control of weld parameters. Welders can adjust the parameters such as the current, voltage, travel speed, gas flow rate, etc., to ensure precise and consistent weld results free of all major and minor weld defects. Other benefits of opting for the GTAW process include:

- The capability of welding in various positions such as overhead, vertical, horizontal, etc.

- Compatible with a wide range of materials, including dissimilar metals.

- Low heat input compared to other welding processes minimizing the risk of distortion.

- Produces a clean and aesthetic weld appearance.

GTAW-P or PAW

Plasma Arc Welding, PAW or GTAW-P, is a welding process that uses a highly concentrated, high-temperature plasma arc to melt and join the workpiece. Like GTAW, the process involves selecting electrodes and shielding gas. The next step is the generation of the plasma arc, which is done by passing a high-velocity gas, which typically includes argon or a mixture of argon and hydrogen, through a narrow nozzle opening. The temperature of the plasma arc may reach temperatures as high as 30,000°F. When such high-temperature plasma is directed toward the metal, it melts the workpiece to create a weld joint.

A few key features of the GTAW-P process include:

- High heat concentration due to the plasma arc resulting in deeper penetration and faster welding.

- Excellent control over the weld parameters.

- Compatible with a wide range of materials, including ferrous or non-ferrous.

- High plasma density enables deep penetration, which means it is suitable for the thickest of metals.

- The reduced heat-affected zone (HAZ) minimizes the chance of distortion or warping.

The table below summarizes the comparison between the GTAW vs. GTAW-P(PAW) welding process.

| GTAW vs. GTAW-P(PAW) | ||

| GTAW | GTAW-P or PAW | |

| Arc generation | Between tungsten electrode and workpiece | The plasma arc is generated by passing high-velocity gas through a narrow orifice |

| Heat concentration | Lower heat concentration | High heat concentration |

| Welding speed | Slower welding speed | Faster welding speed |

| Power requirement | Lower power level | High power level |

| Material thickness | Suitable for thin metals | Suitable for thick and thin material |

| Cost | Lower equipment cost | High equipment cost – requires specialized equipment for plasma generation |

Despite the differences, both welding approaches produce high-quality and precise weld results when welding complex joint designs.

Which Is The Best Welding Approach?

The factors mentioned above are the leading facets that should be considered before selecting the best welding approach. Generally, the following scenarios should be considered.

| Selecting The Ideal Welding Type | |

| GTAW | GTAW-P |

| When joining thinner metalsWhen high precision and control are requiredWhen the welding is of small scale. The welding equipment is compact, easier to handle, and portableSuitable for welding materials such as titanium, stainless steel, and aluminum | When welding thicker metalsWhen you require higher productivity, i.e., for high-speed weldingWhen heavy fabrication has to be done in the industrial settingSuitable for welding ferrous and non-ferrous metals as well as exotic alloys |

When it comes to precision welding, both GTAW and GTAW-P offer their own unique advantages. While GTAW excels in terms of weld quality, versatility, and compatibility with different metals, GTAW-P is the perfect option if you are looking for concentrated heat input and faster welding.

Before deciding the best option between GTAW vs. GTAW-P(PAW), it is essential to consider the complexity of the process and quality requirements for the industry. It is always a good idea to consult expert welding professionals and the related industry standards. With informed decisions, you are sure to achieve high-quality and precise results that meet your project’s specifications.

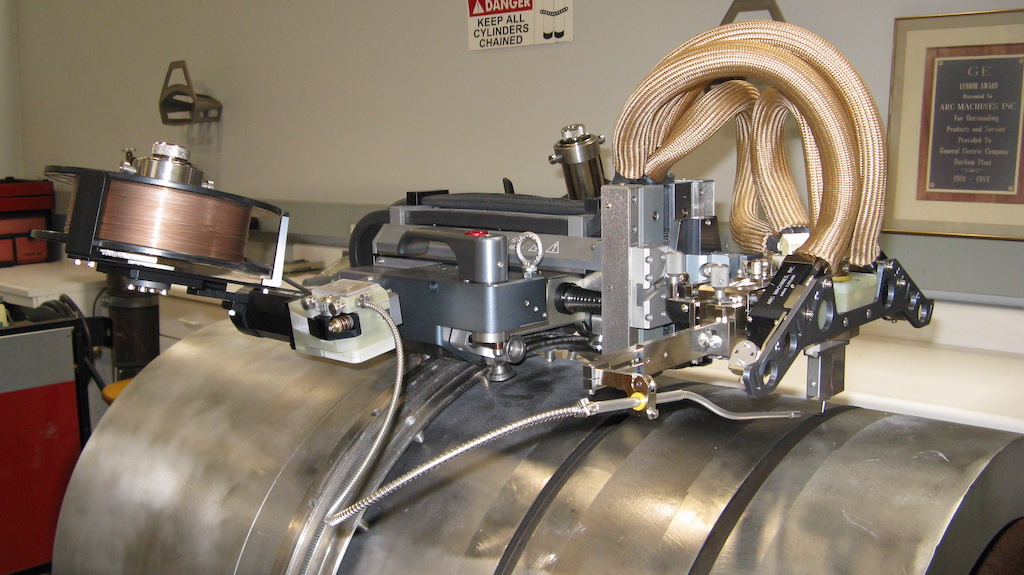

Arc Machines, Inc has been a leading provider of orbital welding solutions for decades. Our unique welding solutions have allowed industries to achieve high-quality, productivity, and efficiency requirements. Contact us today to learn more about the selection criteria between GTAW vs. GTAW-P(PAW) or any other inquiries you may have about your project.